Vehicle-mounted movable multifunctional sludge treatment vehicle

A sludge treatment vehicle, multi-functional technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as time-consuming and cost-consuming, long processing time, and danger, and achieve Reduce the number of people going down to the well to clean up, reduce the cost of cleaning and transportation, and facilitate the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

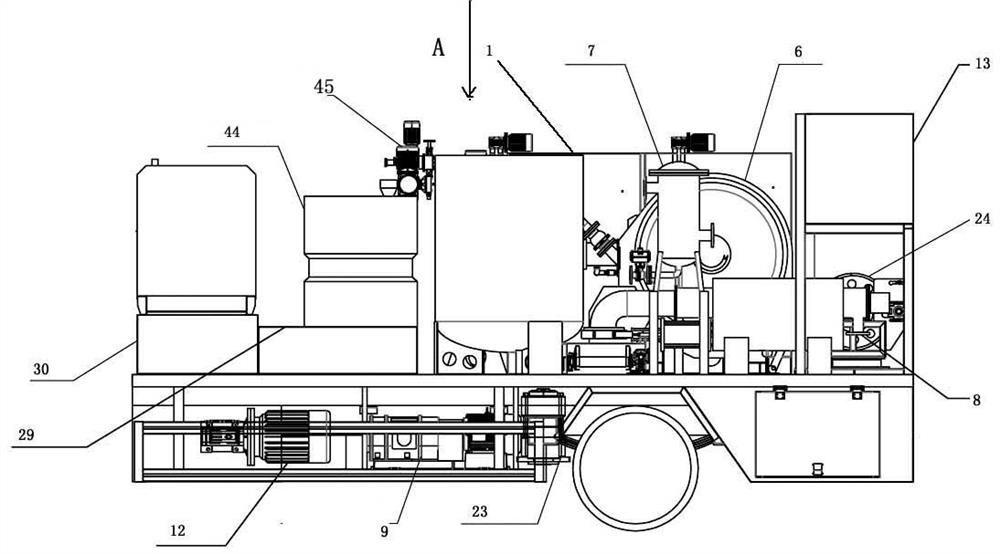

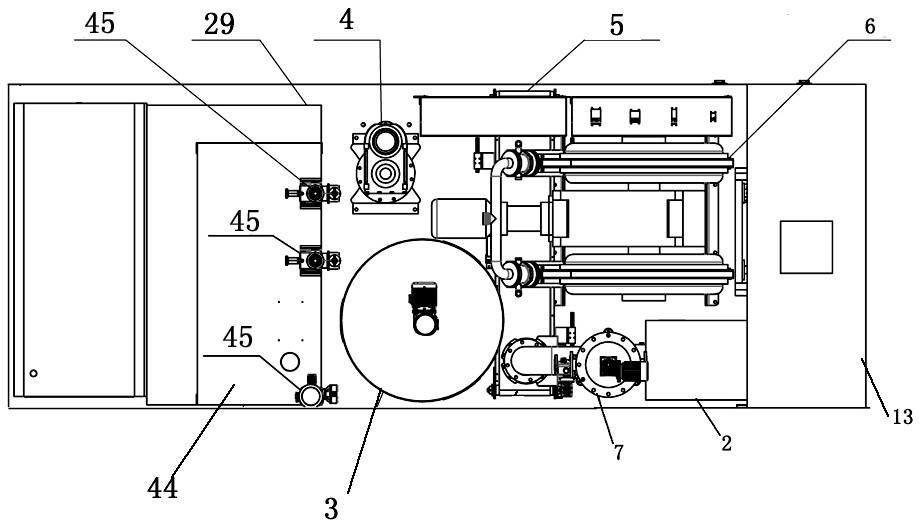

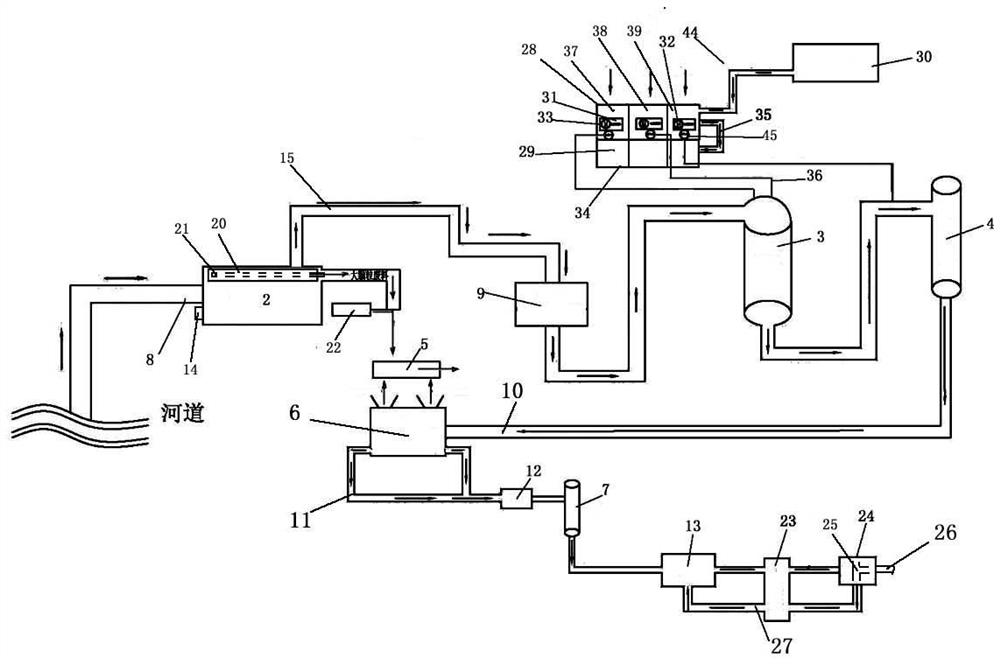

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a vehicle-mounted mobile multifunctional sludge treatment vehicle according to the present invention includes a vehicle body 1 with wheels, and the vehicle body 1 is respectively provided with a coarse filter device 2, a mixing tank 3, and a flocculation tank 4 , conveyor belt 5, main engine 6, filter 7, the front of the coarse filter 2 is connected to the external sewage suction port 8, and one end of the rear is connected to the conveyor belt 5 to transmit the large particle mud, and the other end passes through the rotor pump 9 to remove the remaining Part of the small particle mud is pumped into the mixing tank 3. The rear of the mixing tank 3 is connected to the flocculation tank 4 and the main machine 6 in turn. One side of the main machine 6 is provided with a sewage outlet 10, and the two sides of the bottom are respectively provided with draina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com