Labeling device for freeze-dried powder injection production

A technology of freeze-dried powder injection and fixing plate, which is applied in the field of labeling devices for freeze-dried powder injection production, and can solve the problems of inconvenient operation, difficult device clamping and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

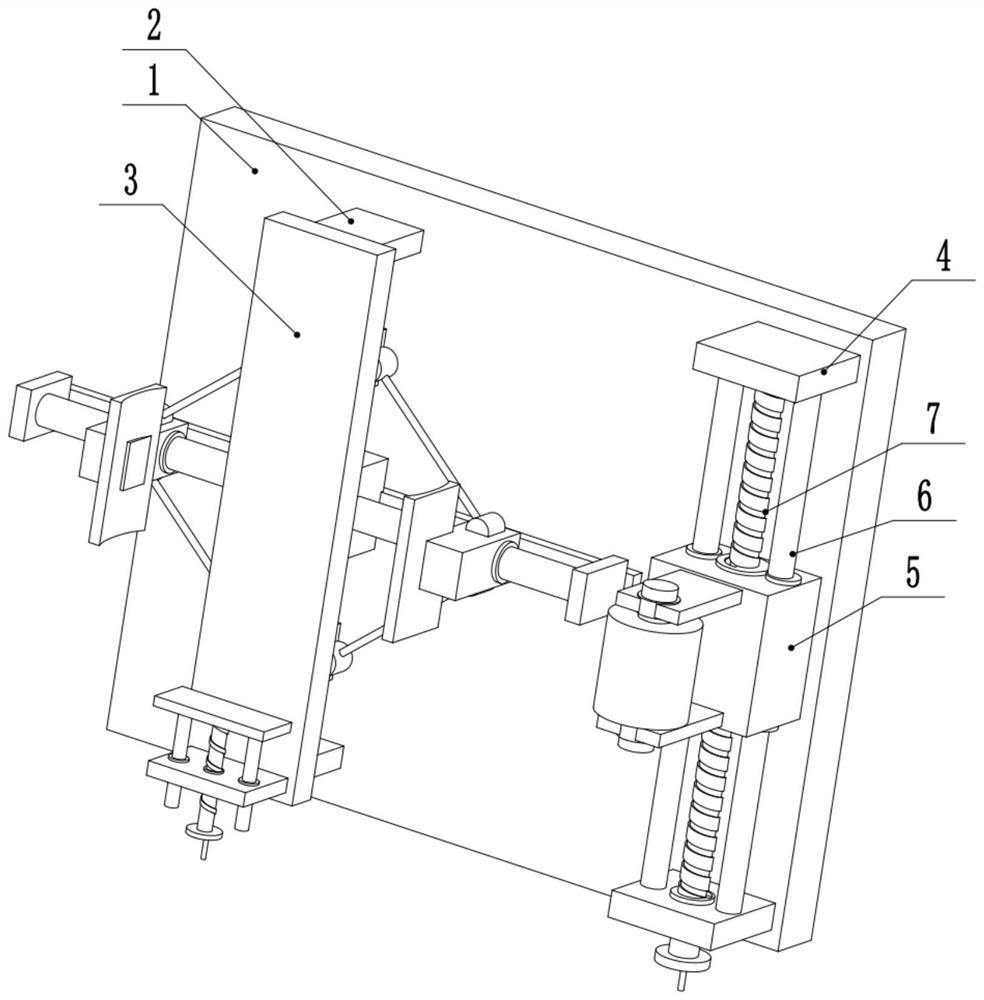

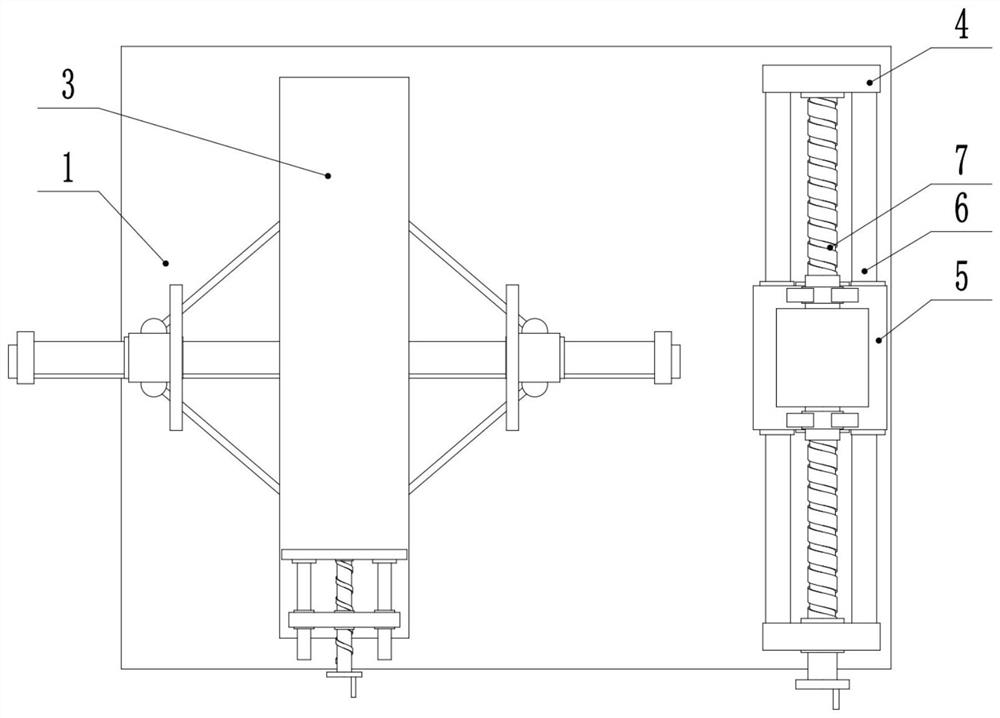

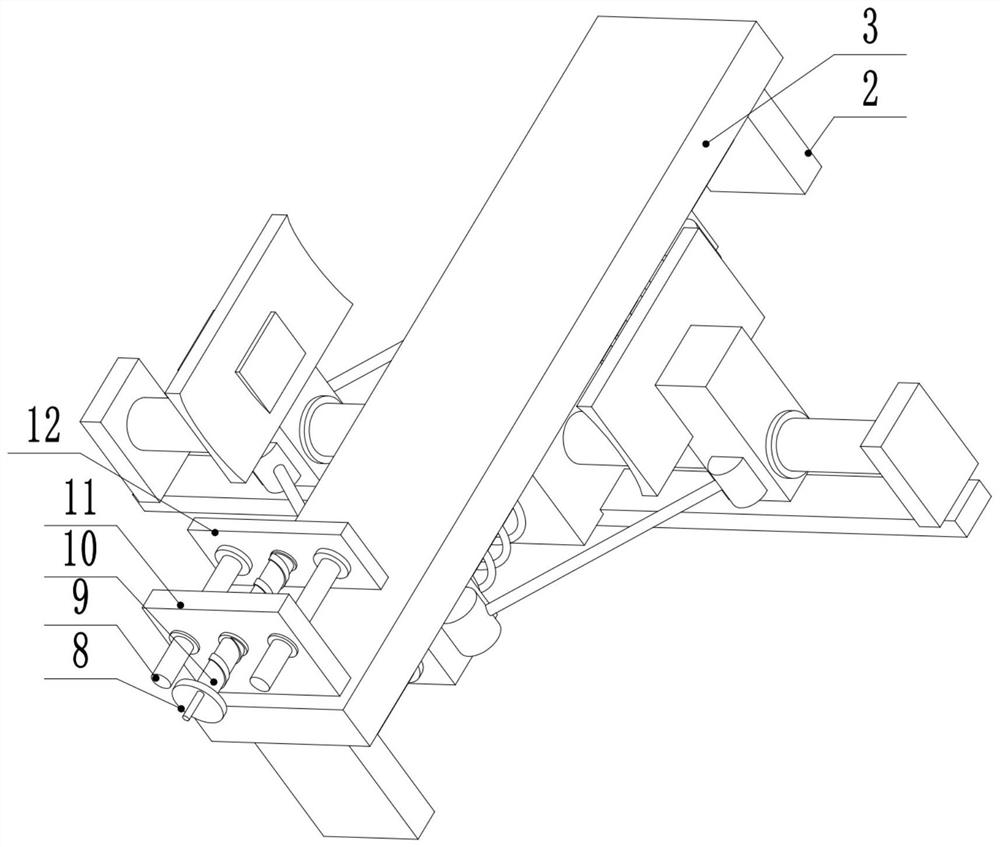

[0028] see Figure 1-5 , a labeling device for the production of freeze-dried powder injections, comprising a base plate 1, the left side of the base plate 1 is provided with a first fixing plate 2, the front end of the first fixing plate 2 is fixedly connected to the upper and lower sides of a fixing table 3, and the fixing The rear side middle part of platform 3 is provided with fixed seat 13, and the upper and lower sides of fixed seat 13 is provided with first slide bar 14, and one end of first slide bar 14 away from fixed seat 13 is fixedly connected to the middle part of first fixed plate 2, the second The middle part of a sliding rod 14 is slidably connected to the first slider 16, and a spring 15 is arranged between the first slider 16 and the fixed seat 13, and the spring 15 is sleeved in the middle part of the first guide rod 6, and the left and right sides of the fixed seat 13 Both sides are provided with the second slide bar 17, the middle part of the second slide ...

Embodiment 2

[0031] see Figure 5 , the second embodiment is improved on the basis of the first embodiment, the fifth fixing plate 23 clamps the upper and lower ends of the rotating shaft 24 . In order to facilitate the clamping of the label paper, the rotating shaft 24 and the fifth fixing plate 23 are arranged in a clamping connection mode. Before using the device, the label paper is first set on the outside of the winding roller 25, and the rotating shaft 24 is stuck on the fifth fixed plate. On the fixed plate 23, when the label paper needs to be used, only the free end of the label paper needs to be pulled. At this time, the winding roller 25 rotates around the rotating shaft 24, so that the label paper is pulled out, thereby enabling the use of the label paper.

[0032] In the present invention, during use, first place the device on the ground, wrap the label paper on the outside of the winding roller 25, pull the left clamping plate 20 to the left, place the packaging bottle on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com