Hole puncher for paper punching

A technology for hole punching and holes, which is applied in the field of hole punching, can solve the problems of not having automatic centering, punching misalignment, etc., and achieve the effect of increasing the waste material storage space and sharp knife edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

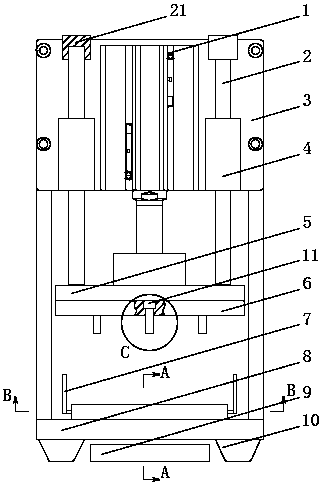

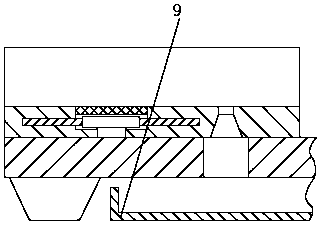

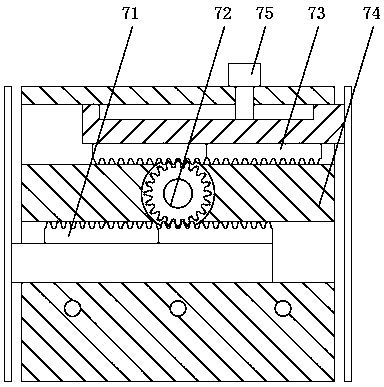

[0026] combined with Figure 1-4 As shown in the figure, a hole puncher for paper punching includes a vertical plate 3 arranged in order from top to bottom, a cover plate 5 slidably connected with the vertical plate 3 up and down, a cutter fixing plate 6 fixedly connected with the cover plate 5, a clamp 7. The bottom plate 8 and the waste box 9 connected with the fixture 7; the vertical plate 3 is provided with a driving device for driving the sliding of the cover plate 5; the cutter fixing plate 6 is provided with a punching knife 11; The fixedly connected mounting plate 74 , the gear 72 rotatably provided in the mounting plate 74 , the first baffle plate 71 slid left and right on the mounting plate 74 , the second baffle plate 73 slid left and right on the mounting plate 74 ; the axis of the gear 72 The first baffle plate 71 and the second baffle plate 73 are arranged opposite to each other and both have racks that mesh with the gear 72 .

Embodiment 2

[0028] In order to better implement the present invention, on the basis of Example 1, in conjunction with the following Figure 1-4 As shown, further, the driving device includes a cylinder 1 with one end connected with the vertical plate 3 and the other end connected with the cover plate 5, a bushing 4 fixedly connected with the vertical plate 3, slidingly arranged in the bushing 4 and connected with the cover The guide rod 2 to which the plate 5 is connected.

Embodiment 3

[0030] In order to better implement the present invention, on the basis of Example 1, in conjunction with the following Figure 1-4 As shown, further, four corners of the lower end surface of the bottom plate 8 are provided with height-enhancing rubber pads 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com