Generator transformer and power generation system

A power generation system and transformer technology, applied in the direction of transformers, transformer/inductor magnetic cores, transformer/inductor components, etc., can solve problems such as difficult to meet steam turbine generator sets, achieve far-reaching economic and social benefits, and huge costs Advantages, the effect of reducing magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

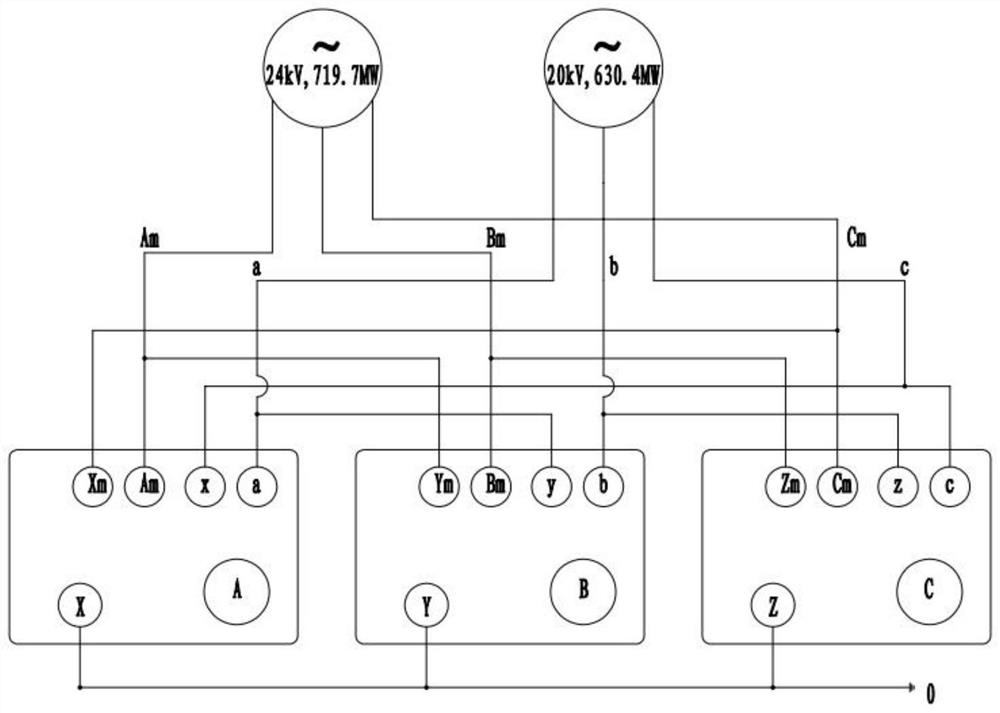

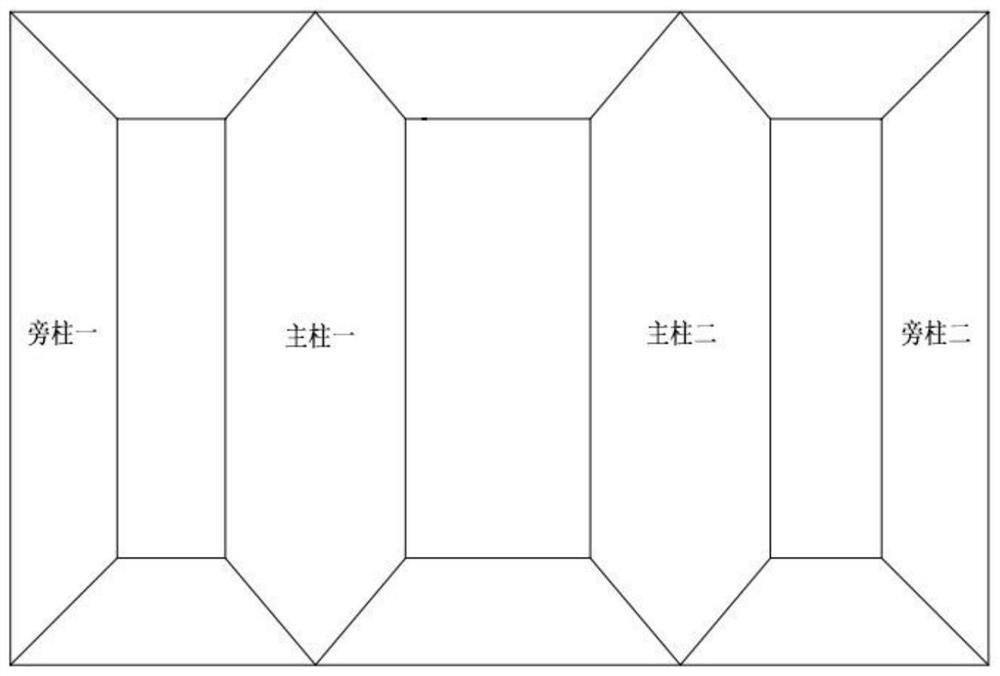

[0027] Such as figure 1 As shown, the generator transformer is a three-phase split structure, which is composed of three single-phase transformers. The iron core of any single-phase transformer is a four-column structure, two main columns and two side columns.

[0028] Such as image 3 As shown, the high-voltage coil 1 7 and the low-voltage coil 1 2 are arranged on the main column 1 core, and the high-voltage coil 2 16 and the low-voltage coil 2 11 are arranged on the main column 2 iron core.

[0029] According to the capacity and output voltage of the generator set, the capacity of main column 1 and main column 2 can be set, as well as the voltage of low-voltage coil 1 and low-voltage coil 2. Low-voltage coil 1 and low-voltage coil 2 can be connected to different capacities and output voltage levels generator set.

[0030] Such as Figure 4 The generator coil structure shown includes coil assembly structure 1 and coil assembly structure 2; coil assembly structure 1 is comp...

Embodiment 2

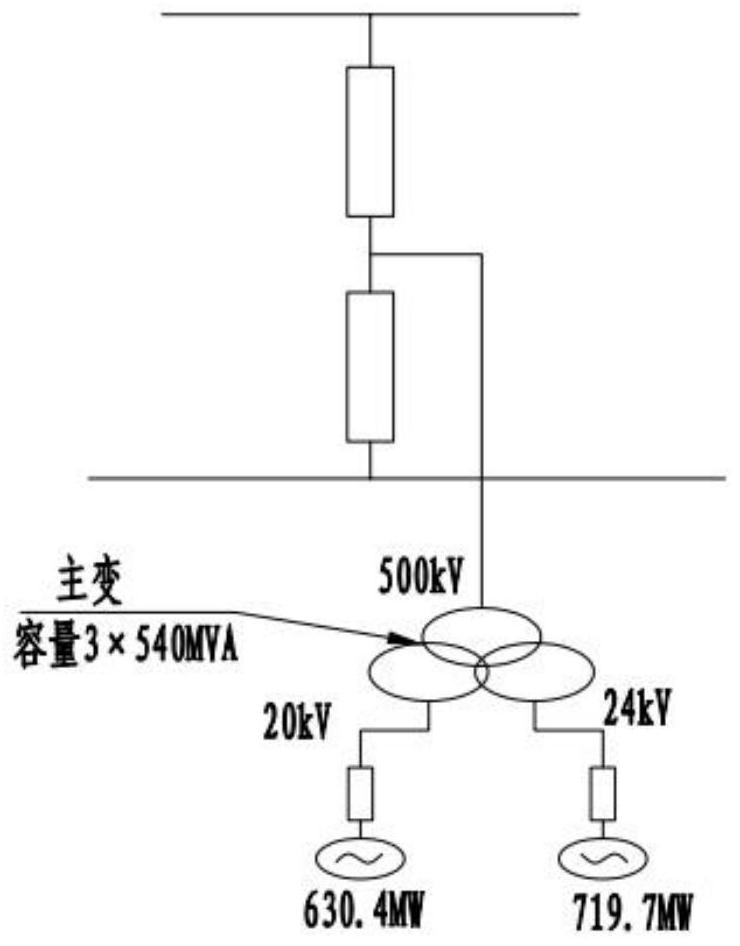

[0040] On the basis of the above embodiments, the present invention also provides a power generation system, see figure 2 , the power generation system includes 2 generator sets and the above-mentioned generator transformer, and the transformer is connected to the generator set and the power grid.

[0041] Specifically, the low-voltage side of the transformer is connected to the generator set, and the high-voltage side of the transformer is connected to the grid, which is used to convert the voltage of the generator set and output it to the grid for use by users.

[0042] The above-mentioned power generation system can greatly reduce the construction cost of the power station due to the adoption of the above-mentioned generator transformer, has a huge cost advantage, and at the same time occupies a smaller area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com