Plate heat exchanger

A technology of plate heat exchangers and plates, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the unfavorable weight and volume of heat exchanger products, increase the resistance of fluid flowing through the flow channel, and the fluid Problems such as small flow resistance can improve heat transfer and transportation, expand effective cross-sectional area, and achieve good heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

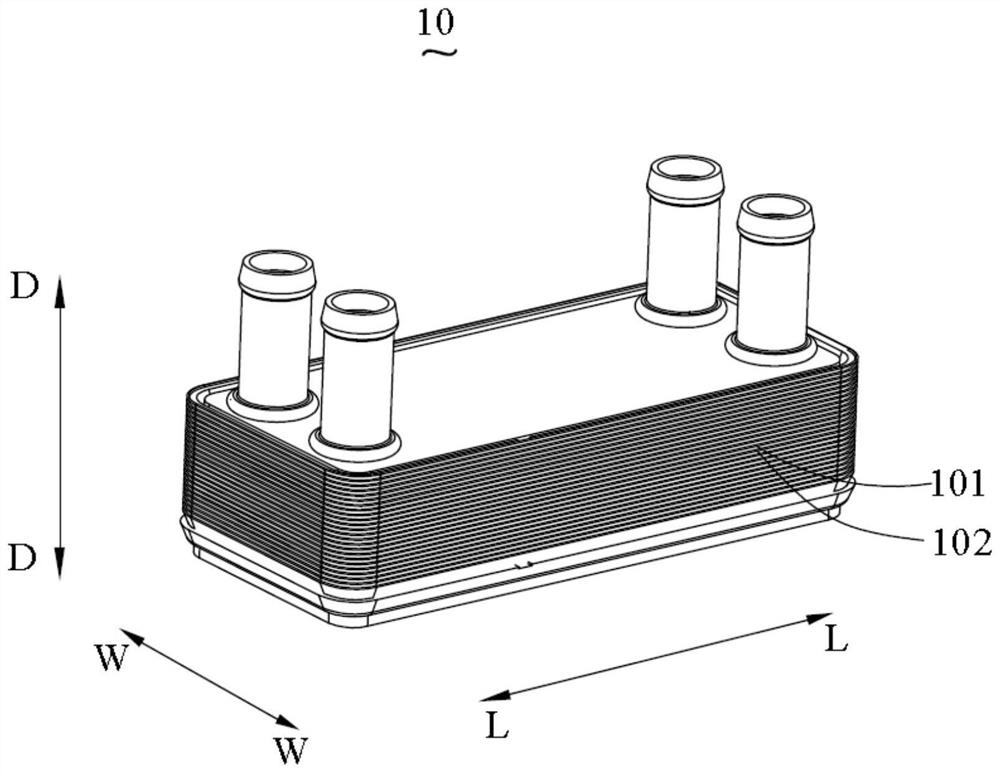

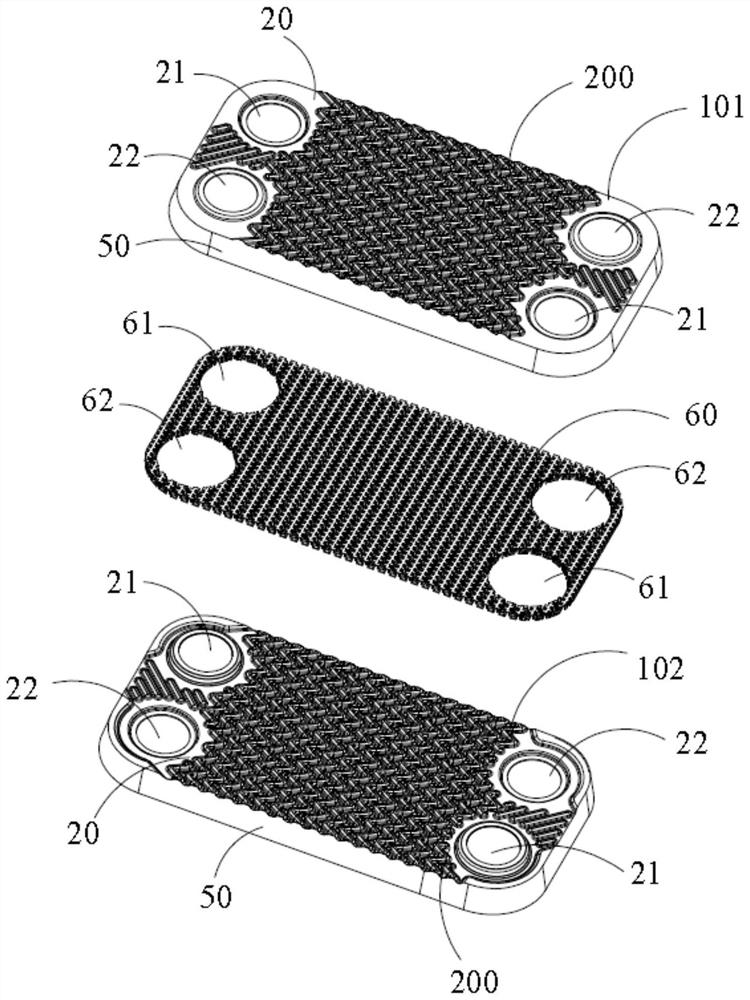

[0033] refer to figure 1 , the present application provides a plate heat exchanger 10, which includes several plates and at least one fin plate 60. Specifically, the fin plate 60 can be fixed between the two plates by brazing. The several plates include a first plate 101 and a second plate 102, and the number of the first plate 101 and the second plate 102 may be multiple. Of course, the plate heat exchanger 10 may also include other third, fourth, fifth plates, etc. which are different in structure from the first plate 101 and the second plate 102 .

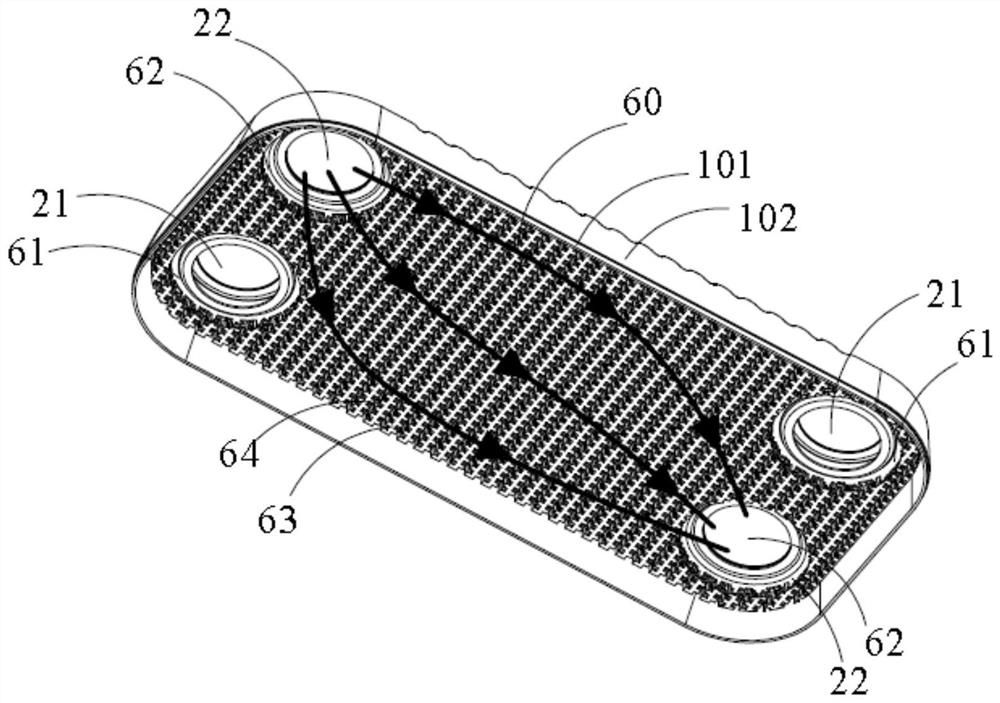

[0034] In some embodiments, refer to figure 2 , the fin plate 60 is located between the reverse surface 300 of the first plate 101 and the front surface 200 of the second plate 102 . The reverse side of the plate 300 figure 2 not shown, refer to Figure 4 As shown in the exploded schematic diagram, the fin plate 60 can increase the heat exchange area of the fluid flowing between the reverse surface 300 of the first plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com