Medium-temperature high-humidity noodle drying process

A noodle and medium temperature technology, applied in drying, drying machine, baking and other directions, can solve the problems of unsatisfactory effect, long drying room length, broken bars, etc., achieve chewy texture, avoid internal and external stress differences, and delay drying speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

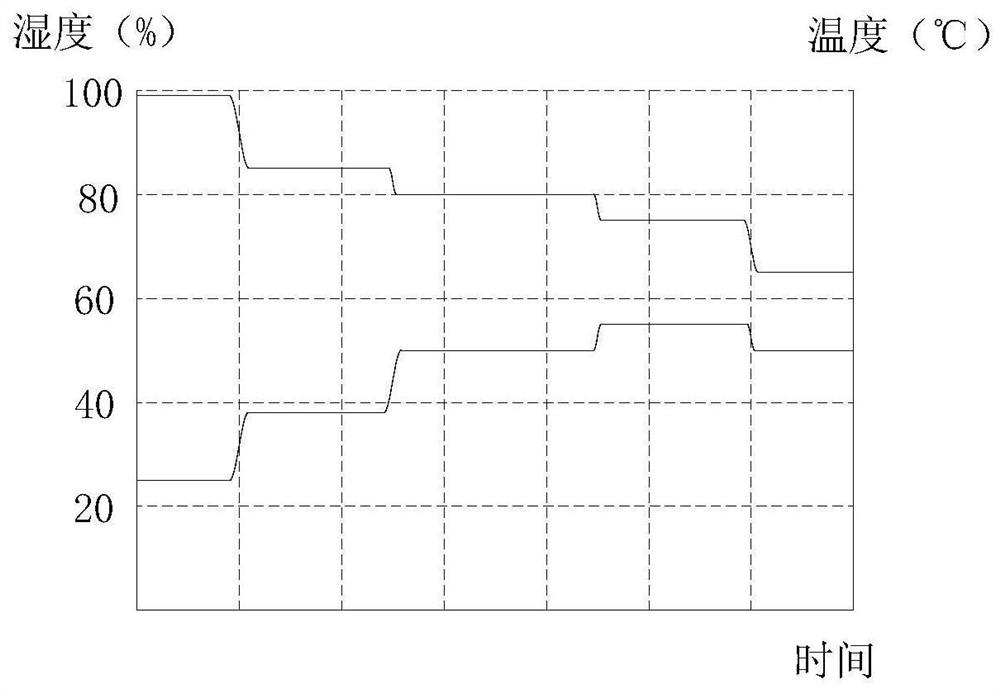

[0024] Such as figure 1 As shown, in the medium-temperature and high-humidity drying process of noodles in this embodiment, the noodles after cutting are sent to the drying room for drying in stages. The noodles are noodles with a diameter (or thickness) of 1.0 mm, and the initial humidity in the drying room is 98 %, reduce the air humidity in each stage to 65% in turn, the initial temperature in the drying room is 25°C, first increase the temperature in the drying room to 55°C, and then reduce the drying temperature to 50°C in the last stage, the moisture content inside the noodles at each stage The difference with the moisture content of the skin is less than 2%, and then the noodles are sent out of the drying room to cool naturally. When leaving the drying room, no conjunctiva is formed on the surface of the noodles.

[0025] The noodles are sent to the drying room for drying in five stages. The drying time ratio of each stage is 10:15:20:15:10, and the air humidity of each...

Embodiment 2

[0031]This embodiment is the same as Embodiment 1, the difference is that the temperature, humidity, and drying time in the drying room are fine-tuned within a certain range. For noodles with different diameters or thicknesses and different raw materials, the temperature and humidity need to be adjusted to a certain extent. , if the initial humidity is 96%, 97%, 98%, 99% or 100%, and within its range, the temperature and humidity in the subsequent stages can also be fine-tuned, such as reducing the air humidity in turn to 65±5% , the initial temperature in the drying room is 25±2°C, first increase the drying room temperature to 55±2°C, and then reduce the drying temperature to 50±2°C in the last stage, when adjusting the above parameters and subsequent drying time , taking the moisture content requirements of noodles at each stage as an index, generally speaking, after each stage, the moisture content of noodles is 28%, 25%, 20%, 15%, and 12%, and the moisture content error is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com