Sewage pump

A technology for sewage pumps and pump casings, applied in the direction of pumps, pump control, pump components, etc., can solve the problems affecting the progress of the project, reduce the working efficiency of sewage pumps, slow down the flow rate, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

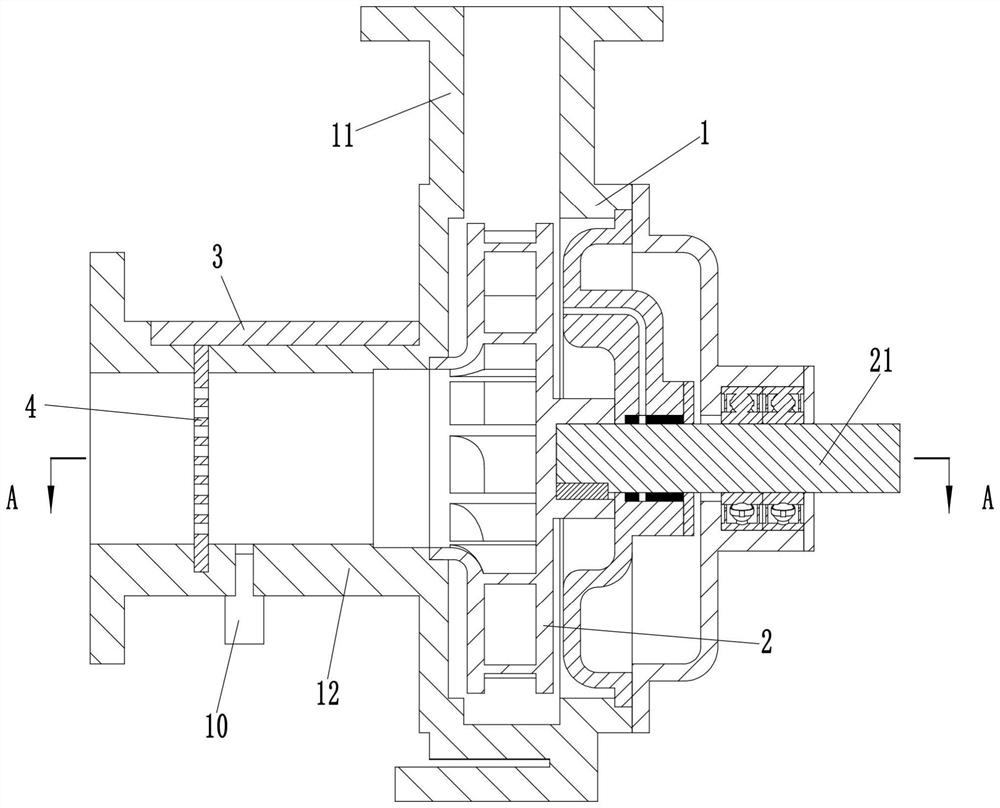

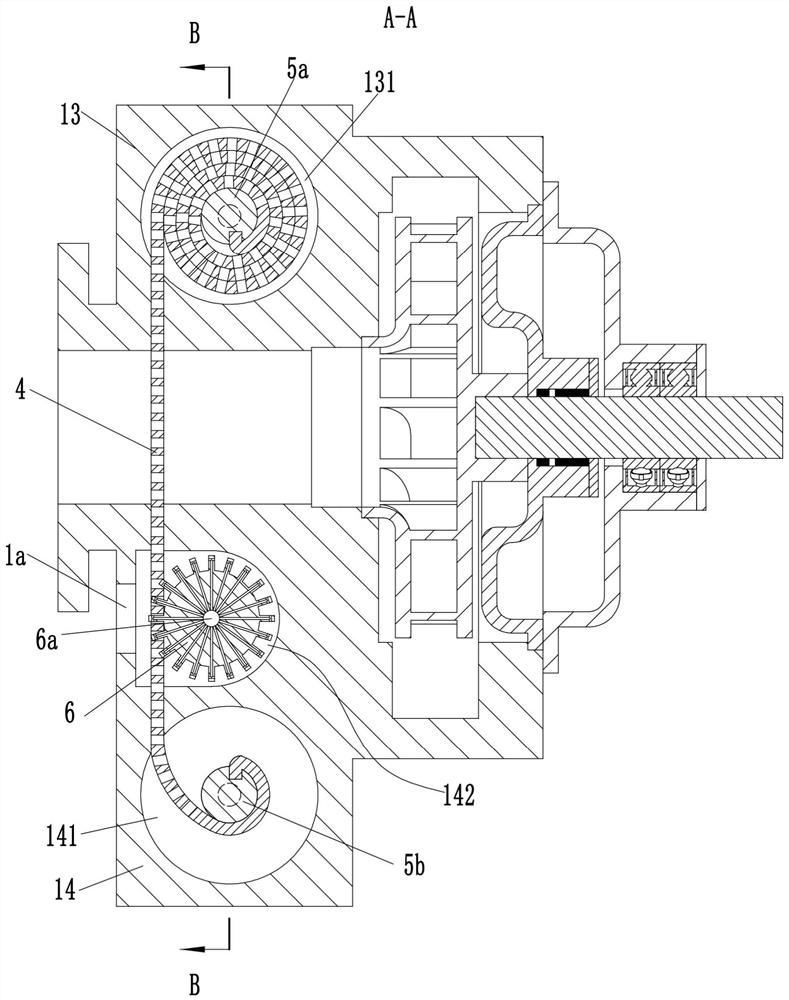

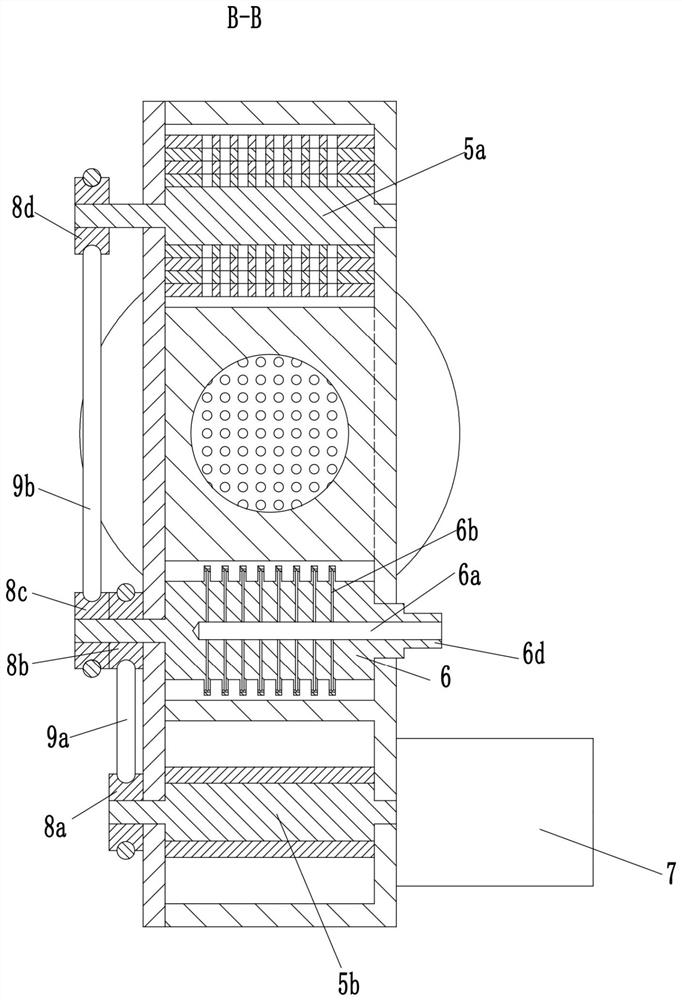

[0019] see Figure 1-4 As shown, the present invention provides a sewage pump, including a pump casing 1, an impeller 2 is arranged inside the pump casing 1, and a power unit fixedly connected with the impeller 2 is provided on the right side of the pump casing 1 to drive the impeller 2 to rotate. shaft 21; the outer side of the pump casing 1 is provided with an outlet pipe 11 along the radial direction of the impeller 2, and an inlet pipe 12 coaxial with the power shaft 21 is provided along the axial direction of the impeller 2; The first bump 13 and the second bump 14 are respectively provided on both sides of the two sides, and the inside of the first bump 13 is provided with a first turning groove 131 along the axial direction perpendicular to the inlet pipe 12, and the inside of the second bump 14 is A second turning groove 141 is arranged perpendicular to the axial direction of the inlet pipe 12, and a third turning groove 142 is arranged between the second turning groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com