Building sewage treatment device

A sewage treatment device and construction technology, applied in the direction of water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of reducing sewage treatment efficiency, unfavorable sewage treatment, and inability to crush solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

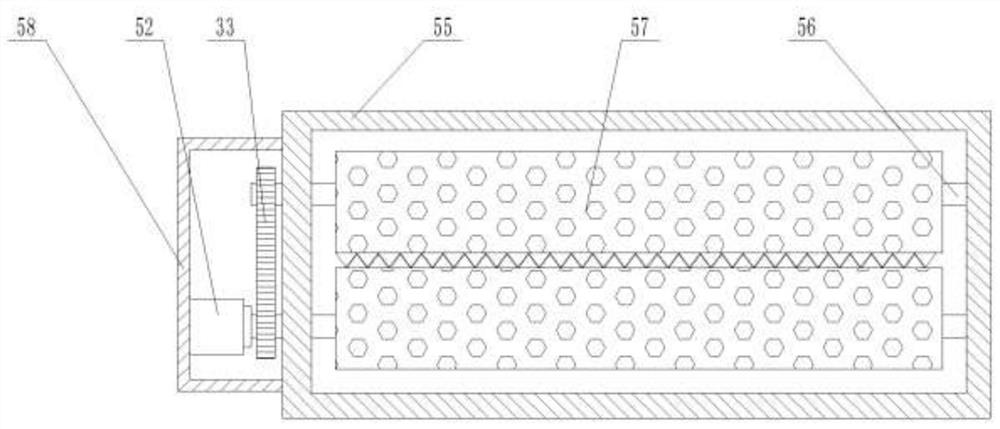

[0023] see Figure 1~Figure 5As shown, a building sewage treatment device includes a base 13, four corners of the lower side of the base 13 are provided with rollers 14, the top left end of the base 13 is provided with a treatment box 1, and the top left end of the treatment box 1 is provided with a fixed frame 55, Two second rotating shafts 56 are rotatably installed in the fixed frame 55, and crushing rollers 57 are fixedly sleeved on the two second rotating shafts 56, and the two crushing rollers 57 are engaged with each other. Protective cover 58, one end of the two second rotating shafts 56 extends into the protective cover 58 and is fixedly sleeved with gear 33, and the two gears 33 are meshed, and the protective cover 58 is fixedly installed on the inner wall of the side away from the fixed frame 55 There is a drive motor 52, the output shaft of the drive motor 52 is fixedly connected to one end of the corresponding second rotating shaft 56, the inner wall of the fixed ...

Embodiment 2

[0030] On the basis of embodiment one, refer to Figure 5 A control panel 2 is arranged on the front top outer wall of the treatment box 1, a first cover plate 23 is arranged on the front bottom outer wall of the treatment box 1, and a second cover plate 41 is arranged on the front outer wall of the disinfection box 39. Can realize intelligent control by arranging control panel 2, reduce manpower operation, have improved work efficiency, by arranging the first cover plate 23 to be convenient to the inspection and maintenance of treatment box 1 inside, also be convenient to replace the first active carbon filter screen 10 and simultaneously The second activated carbon filter screen 12 facilitates the inspection and maintenance of the inside of the disinfection box 39 by setting the second cover plate 41 .

[0031] Working principle: in the process of use, by setting the protective cover 58, the gear 33, the drive motor 52, the guide hopper 54, the feed hopper 53, the fixed fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com