Salt pan slag breaking method

A salt field and slag breaking technology, applied in the direction of alkali metal chloride, etc., can solve problems such as low work efficiency, achieve the effect of improving work efficiency, avoiding repeated breaking of slag and omission of slag breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for breaking slag in salt fields, specifically comprising:

[0021] Locate the four-corner coordinates of Yantian;

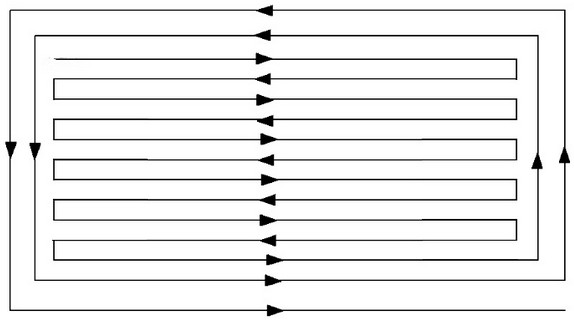

[0022] Plan the walking route of the slag breaking device according to the information of the four positioning points;

[0023] The slag breaking device performs slag breaking processing according to the planned walking route.

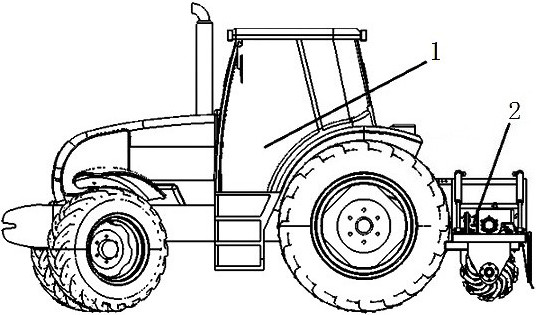

[0024] It should be noted that, as attached figure 2 As shown, the slag breaking device includes a tractor and a slag breaker pulled by the rear of the tractor. The slag breaker is hung on the rear support of the tractor and driven by the tractor rear output shaft.

[0025] Further, the specific method for locating the coordinates of the four corners of the salt field includes installing positioning piles at the four corners of the salt field, the video acquisition device collects the position of the positioning piles as the positioning point information, and transmits the positioning point information to the server, a...

Embodiment 2

[0031] A method for breaking slag in salt fields, specifically comprising:

[0032] Locate the four-corner coordinates of Yantian;

[0033] Plan the walking route of the slag breaking device according to the information of the four positioning points;

[0034] The slag breaking device performs slag breaking processing according to the planned walking route.

[0035] It should be noted that, as attached figure 2 As shown, the slag breaking device includes a tractor and a slag breaker pulled by the rear of the tractor. The slag breaker is hung on the rear support of the tractor and driven by the tractor rear output shaft.

[0036] Further, the specific method for locating the coordinates of the four corners of Yantian includes installing a positioning device on the tractor that pulls the muck breaker, the tractor pulls the muck breaker to the four corners respectively, the positioning device obtains the information of the positioning point, and transmits the information of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com