An integrated electrical module mounting bracket and its assembly

A mounting bracket and integrated technology, applied in the direction of transportation and packaging, circuits or fluid pipelines, vehicle components, etc., can solve the vibration requirements of the controller, can not meet the lightweight requirements of the whole vehicle, integrated installation in a bracket, etc. problems, to achieve good sealing and NVH performance, to solve the low maintenance efficiency, and to solve the effect of difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

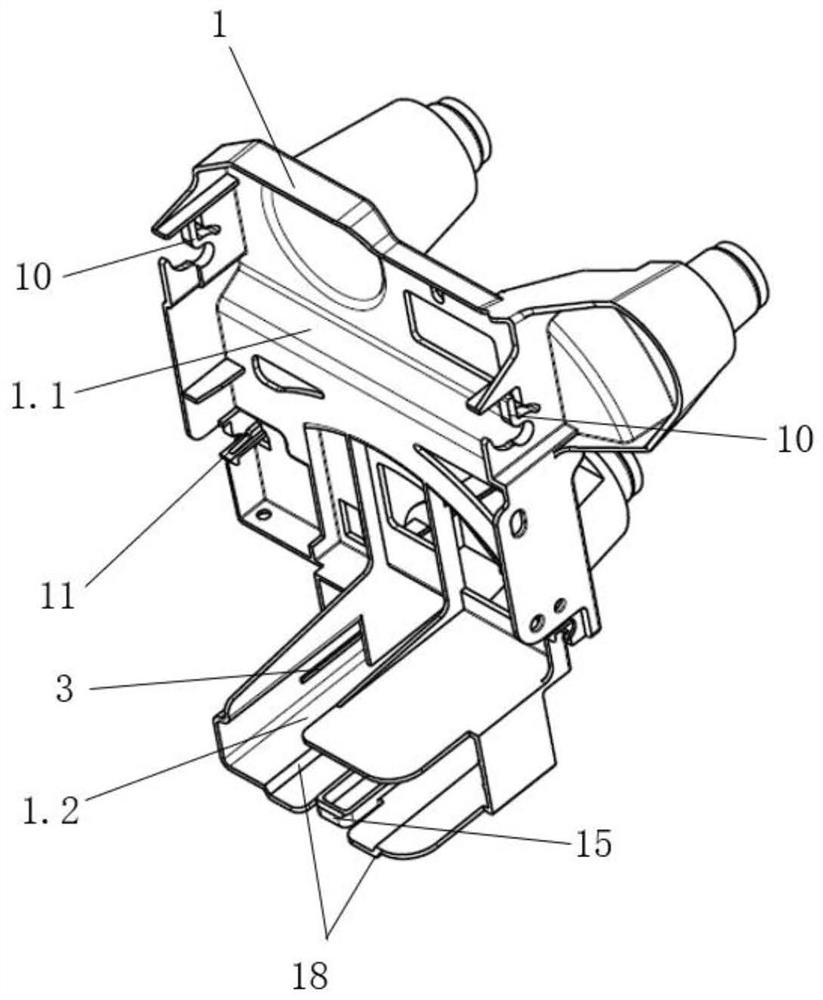

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the invention. The positional relationships described in the embodiments are consistent with those shown in the accompanying drawings.

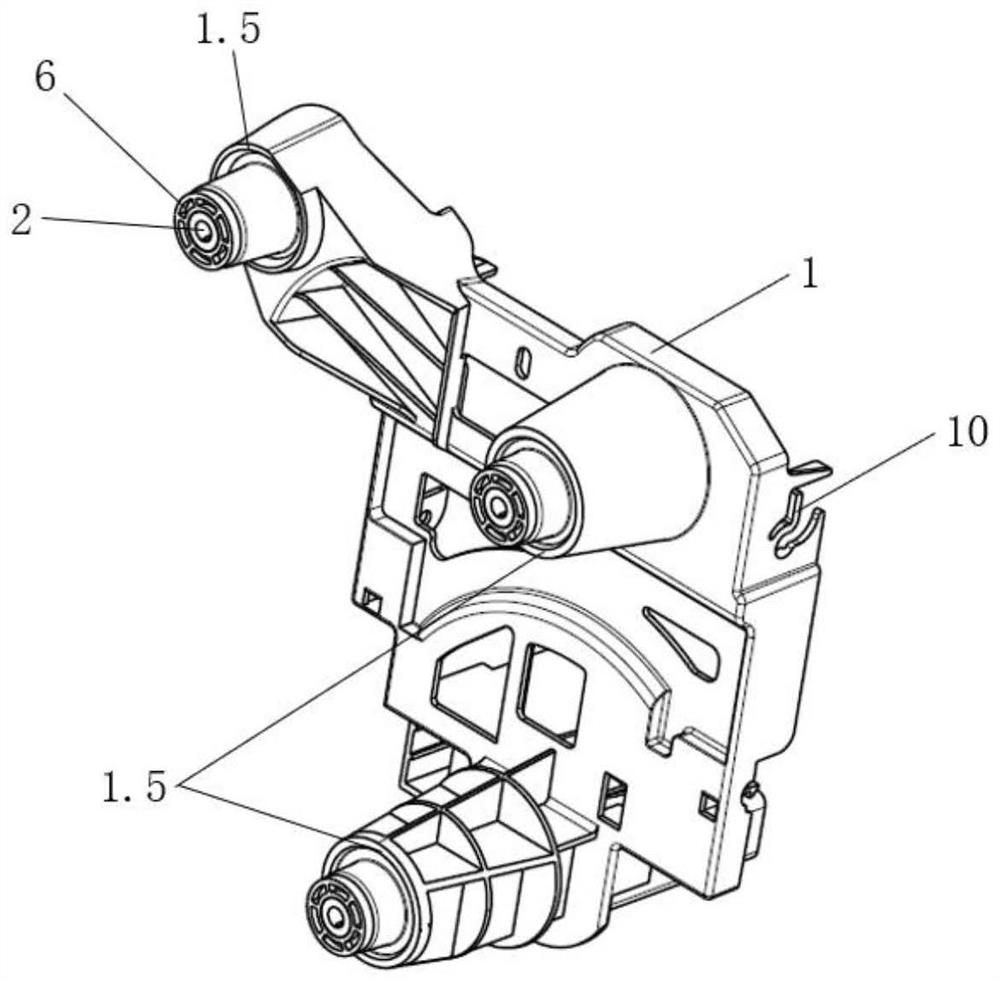

[0037] Such as figure 2 As shown, an integrated electrical module mounting bracket is composed of a mounting bracket body 1, a cushion cushion 6 and a plastic core 2. The structure and connection methods of each part of the mounting bracket will be described below.

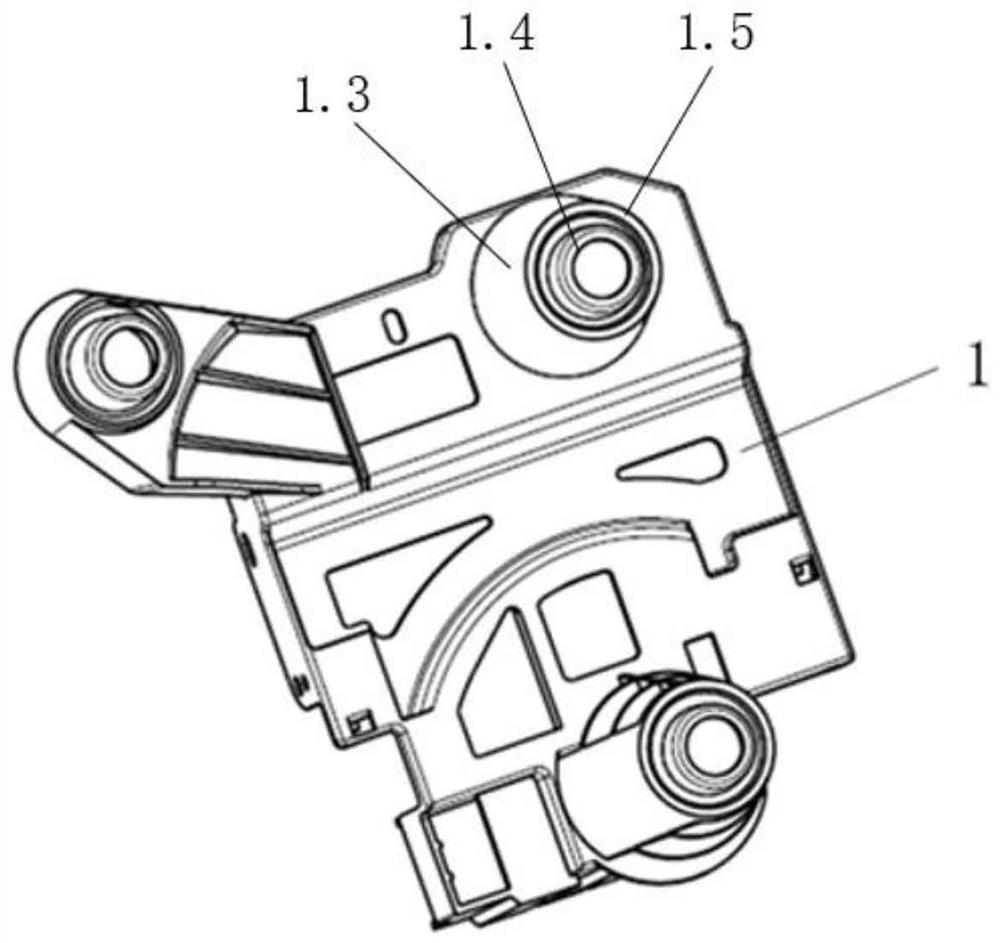

[0038] Mounting bracket body 1 such as figure 1 As shown, one side of the mounting bracket body 1 is provided with three raised hollow columns 1.3, the upper end surface of the hollow column 1.3 is provided with an annular card interface 1.4, and the outer side of the hollow column 1.3 middle part is provided with a raised limiter 1.5. Cushion cushion 6 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com