A dynamic vibration absorber for an electric drive assembly and a dynamic vibration-absorbing torsion-resistant rear mount

A dynamic vibration absorber and dynamic vibration absorption technology, applied in the direction of electric power plant, power plant, vehicle parts, etc., can solve the technical requirements that cannot meet the light weight of electric vehicles, the vibration isolation and fatigue performance of the mount cannot be taken into account, and it cannot adapt to pure electric vehicles. Electric vehicles, such as high torque, achieve the effects of light weight, increased safety and reliability, and improved vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

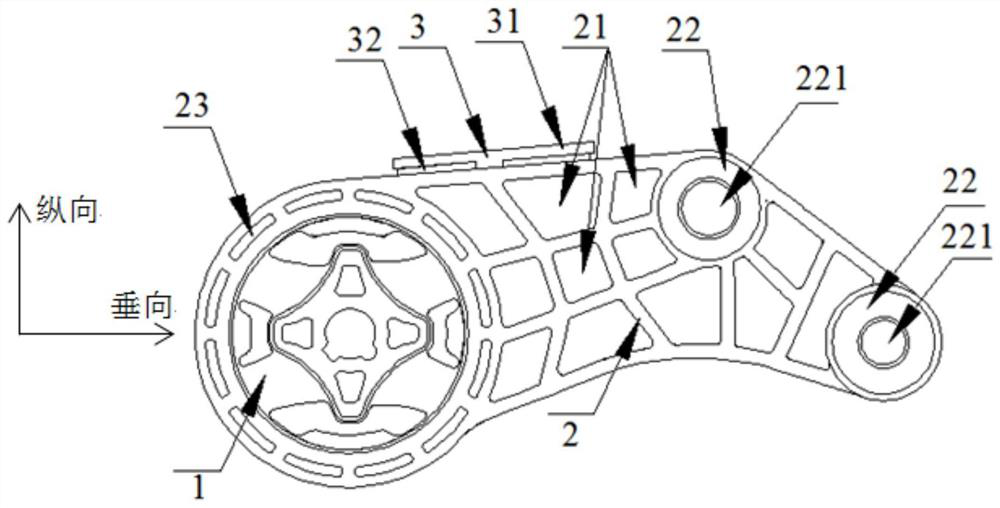

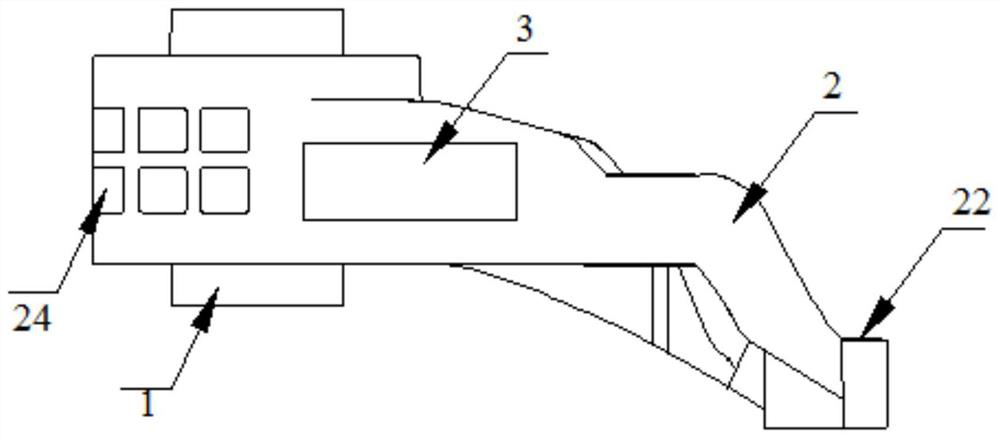

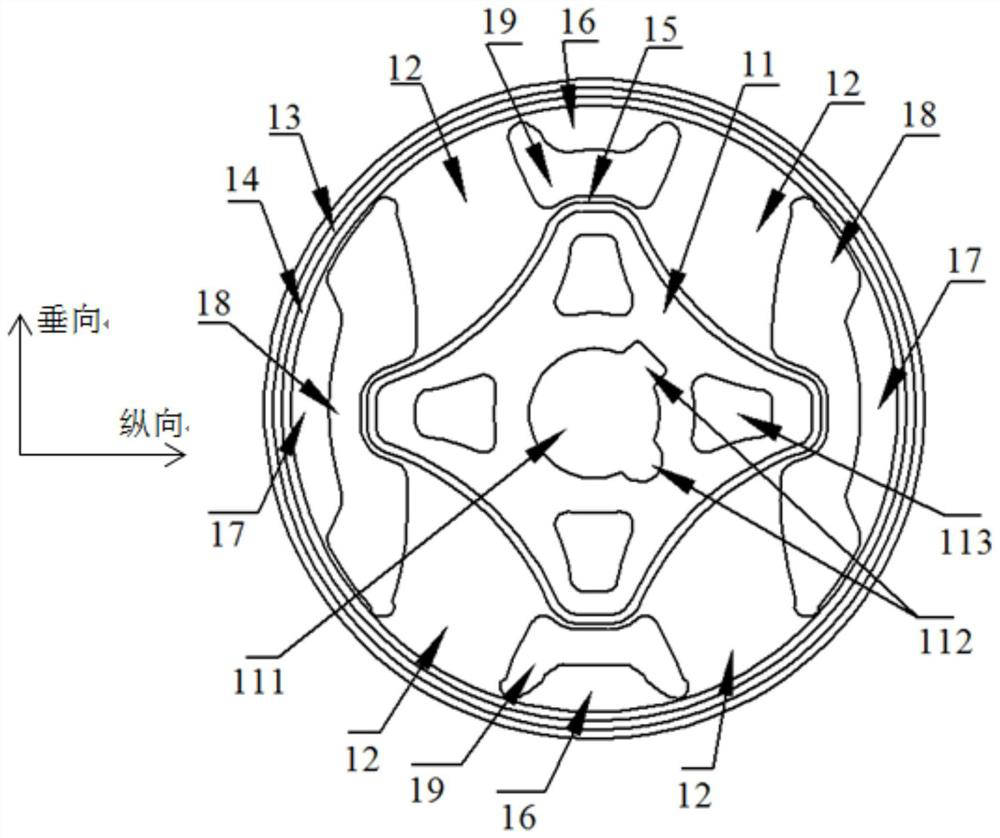

[0029] This embodiment provides an electric drive suspension system. The layout of the electric drive suspension system adopts a three-point centroid layout, including left suspension, right suspension and rear suspension, and the left suspension and right suspension are symmetrically arranged. , its connection line is close to the torsion axis of the electric drive, the rear suspension is far away from the center of mass of the electric drive, and the rear suspension bears much larger vertical and longitudinal forces than the front suspension, among which the vertical force is the largest, so this is It is required that the vertical (vertical) stiffness of the rear sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com