Coated paper film laminating machine auxiliary equipment

A technology of auxiliary equipment and laminating machine, which is applied in the direction of special paper, lamination auxiliary operation, paper, etc., and can solve the problems of inability to process and cut accurate proofreading of coated paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

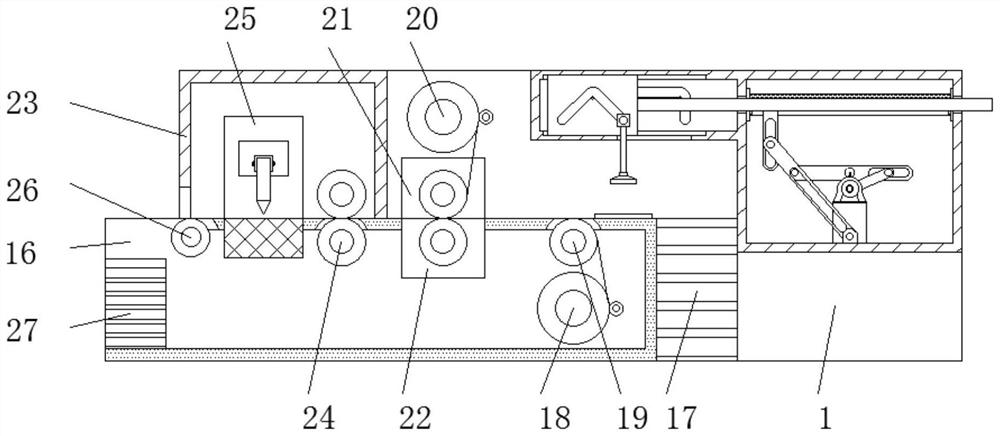

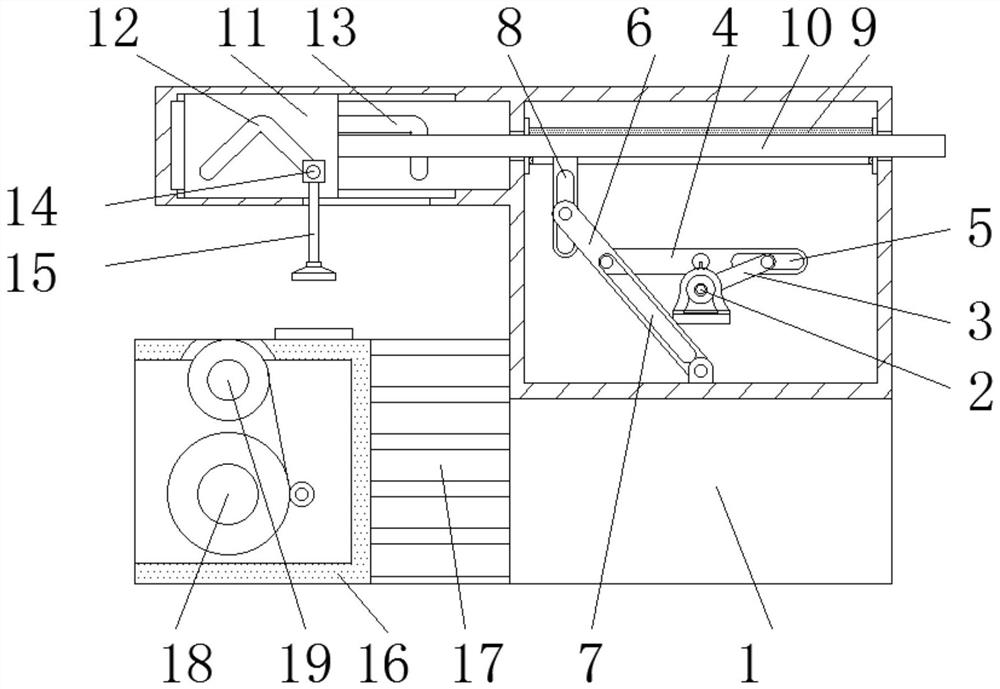

[0030] see Figure 1-7 , an auxiliary equipment for a coated paper laminating machine in an embodiment of the present invention, comprising a feeding frame 1, a motor 2 is fixedly installed on the inner wall of the feeding frame 1, and a first connecting rod 3 is screwed to the output end of the motor 2, The end of the first connecting rod 3 away from the motor 2 is screwed with the first rotating plate 4, and the connecting portion between the first rotating plate 4 and the first connecting rod 3 is provided with a first groove 5, and the first rotating plate 4 is far away from the first rotating plate 4. One end of the groove 5 is located at the inner wall of the feeding frame 1 and is screwed with a second rotating plate 6, and the connection part between the second rotating plate 6 and the first rotating plate 4 is provided with a second groove 7, and the second rotating plate 6 is away from One end of the second groove 7 is screwed with the first orifice 8, and the top ou...

Embodiment 2

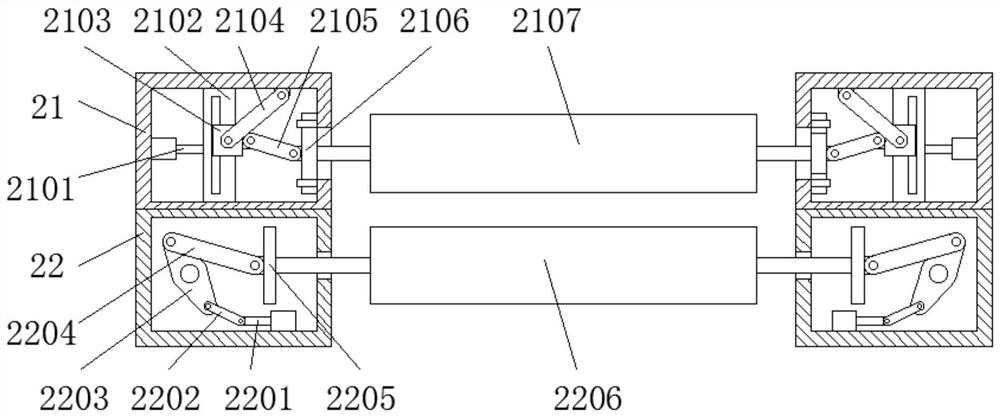

[0032] Compared with Embodiment 1, in this embodiment, the third adjustment box 25 includes a third pneumatic push rod 2501, a third rotating plate 2502, a fifth groove 2503, a sixth connecting rod 2504, a fourth rotating plate 2505, The second orifice plate 2506, the second moving plate 2507 and the knife rest 2508, the inner wall of the third adjustment box 25 is fixedly connected with the third pneumatic push rod 2501, and the output end of the third pneumatic push rod 2501 is located at the third adjustment box 25 The inner wall is screwed with a third rotating plate 2502, and the connection between the third rotating plate 2502 and the third pneumatic push rod 2501 is provided with a fifth groove 2503, and the bottom of the fifth groove 2503 is screwed on the inner wall of the third rotating plate 2502. There is a sixth connecting rod 2504, and the end of the sixth connecting rod 2504 away from the third rotating plate 2502 is located on the inner wall of the third adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com