Air feeding nozzle of automatic press fitting equipment for automobile barometer pointer and using method

A technology for barometers and automobile instruments, which is applied in the field of upper air nozzles of automatic press-fitting equipment for pointers of automobile barometers. Tube burst and other problems to achieve the effect of avoiding tube burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

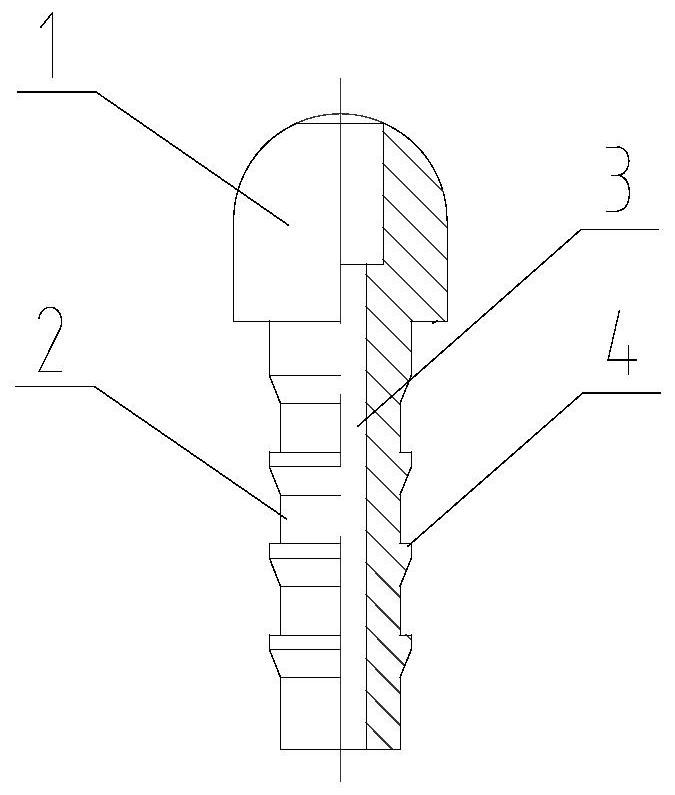

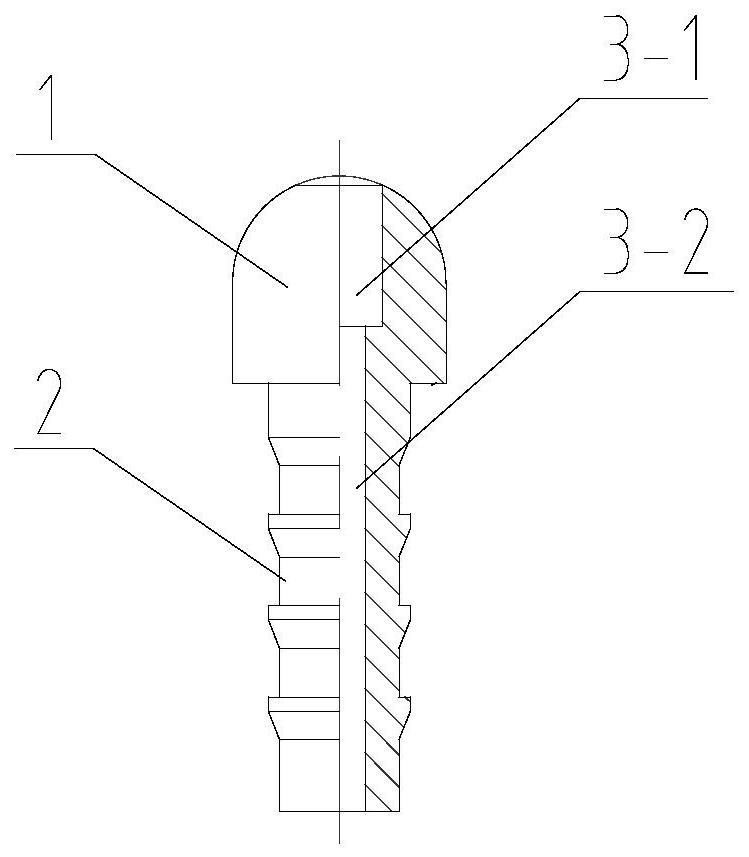

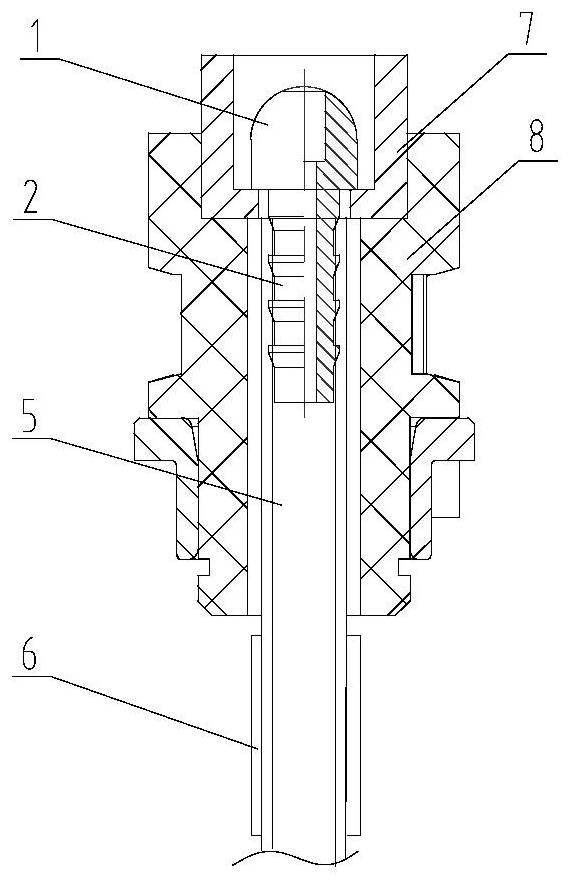

[0029] Specific embodiment one: the upper air nozzle of the automatic press-fitting equipment for the pointer of the automobile barometer, which is characterized in that: the air nozzle includes a head end 1 and a rod end 2, and the head end 1 and the rod end 2 are integrally formed. The top surface of end 1 is hemispherical, the outer end surface of rod end 2 is cylindrical, and the outer end surface of rod end 2 is provided with multi-layer annular protrusions 4 . The inside of the head end 1 and the rod end 2 is provided with a stepped air hole 3 arranged along the central axis.

[0030] In this embodiment, the upper part is made into a hemispherical shape, which is beneficial to closely fit with the ventilation threaded hole of the air pressure pointer of the automobile instrument, so as to prevent air leakage.

[0031] Other specific implementations are the same as the first specific implementation.

specific Embodiment approach 2

[0032] Embodiment 2: The upper air nozzle of the automatic press-fitting equipment for the pointer of the automobile barometer according to claim 1, characterized in that: the outer end surface of the head end 1 is cylindrical.

[0033] Other specific implementations are the same as the first specific implementation.

specific Embodiment approach 3

[0034] Embodiment 3: The head end 1 and the rod end 2 are arranged in a stepped shape, and the outer diameter of the head end 1 is larger than the outer diameter of the rod end 2 .

[0035] In this embodiment, the outer diameter of the head end is larger than the outer diameter of the rod end, in order to limit the specific position during installation.

[0036] Other specific implementations are the same as the second specific implementation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com