Laser cutting slag removing device

A cleaning device and laser cutting technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult cleaning, sawtooth deformation of the workbench, affecting the use of the workbench, etc., to achieve the effect of convenient processing and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

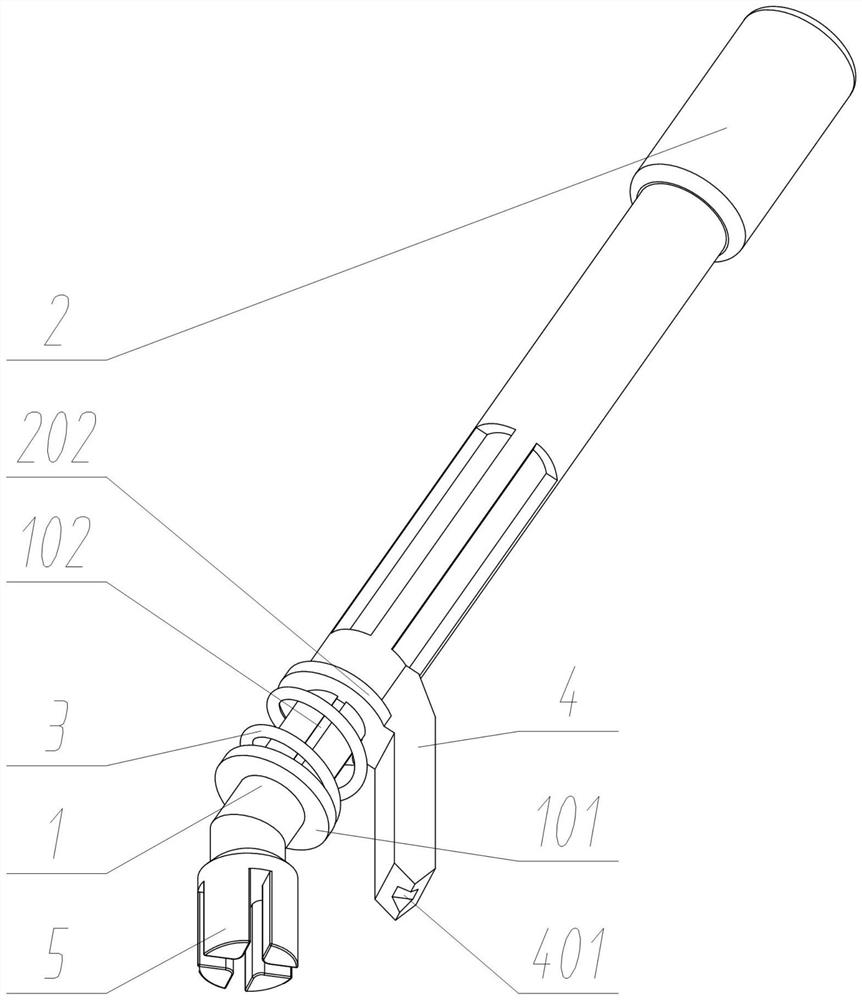

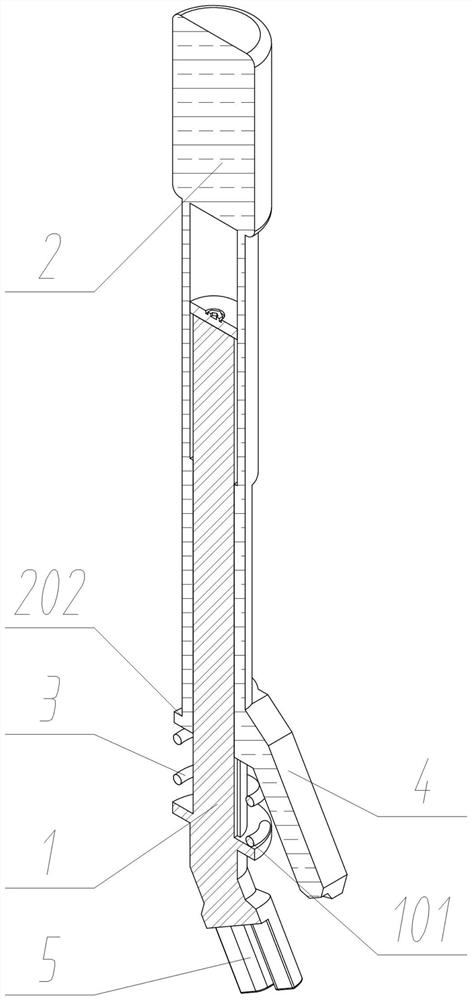

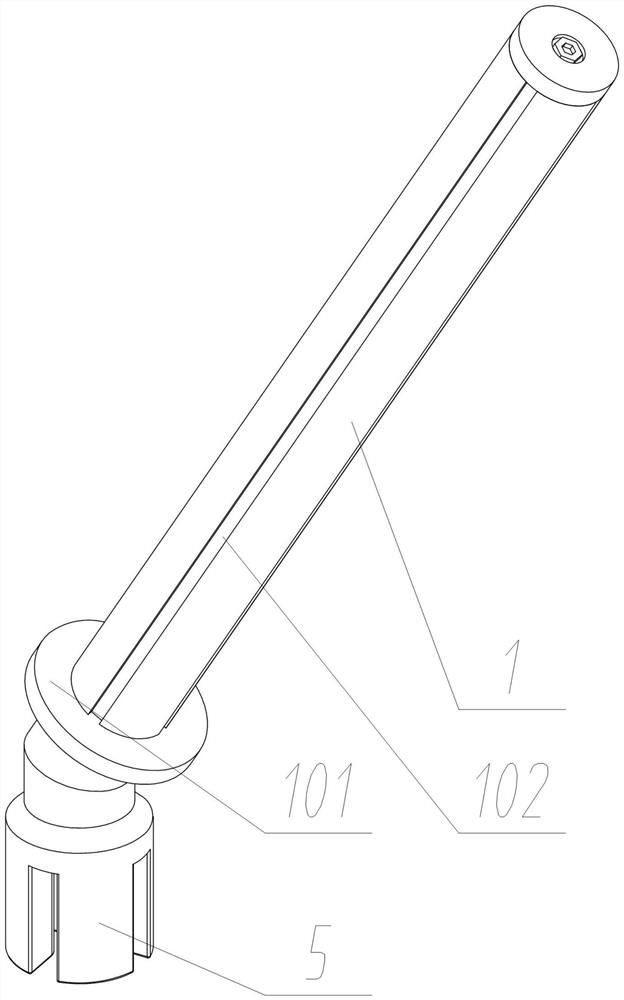

[0024] as attached figure 1 to attach Figure 4 Shown:

[0025] The invention provides a laser cutting slag cleaning device, comprising: a cleaning rod core 1; a group of holding rods 2 are slidably connected to the top of the cleaning rod core 1; A set of support springs 3 is connected; a set of slag cutting scrapers 5 is fixedly connected to the bottom of the cleaning rod core 1 ; a set of crowbars 4 is fixedly connected to the bottom of the holding rod 2 .

[0026] Wherein, the bottom of the cleaning rod core 1 is provided with an annular protruding limiting spring plate 101, and the lower end of the holding rod 2 is provided with a set of corresponding holding rod limiting plates 202, and the two ends of the supporting spring 3 are fixedly connected to the limiting spring respectively. On the plate 101 and the grip bar limiting plate 202, when in use, the supporting spring 3 is installed in the gap between the limiting spring plate 101 and the grip bar limiting plate 202...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com