Dispersive type pulp preparation method

A standardized and dispersed technology, applied in the direction of chemical instruments and methods, mixer accessories, mixers, etc., can solve the problems of pulp cannot be fed effectively, adhesion, and pulp cannot be stirred effectively, so as to improve the feeding diameter and prevent The effect of vortex and easy feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

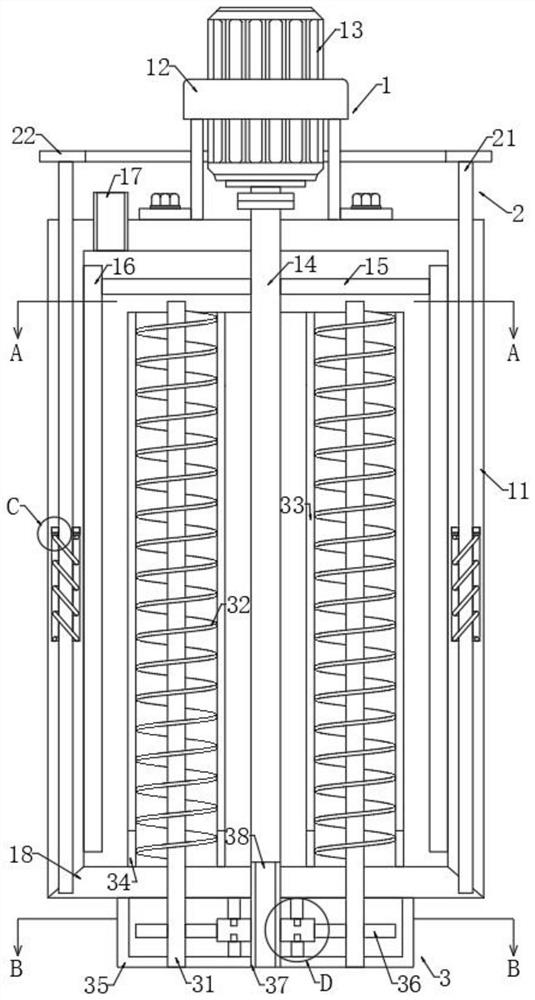

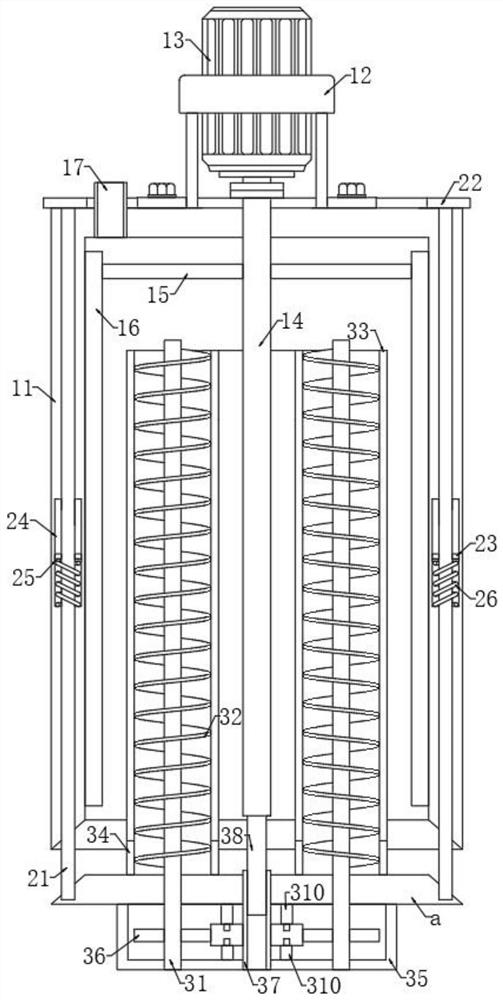

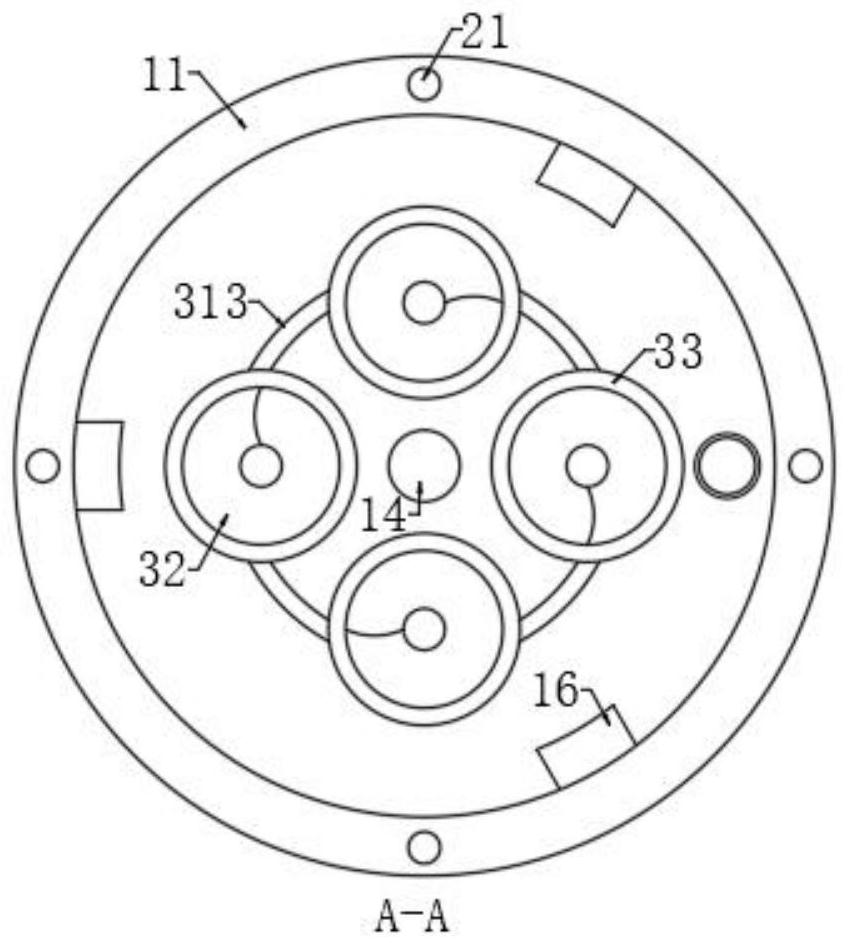

[0029] Such as Figure 1-Figure 7 Shown, a kind of dispersion system pulp method of the present invention, this method comprises the following steps:

[0030] S1: According to the type of pulp that needs to be produced, select the corresponding raw materials for pulping, and initially crush the selected raw materials;

[0031] S2: Remove impurities from the crushed raw materials in S1. After the removal of impurities from the raw materials is completed, put the raw materials together with water into the cooking pot for cooking. After the cooking of the raw materials is completed, take out the raw materials mixed with the liquid for use;

[0032] S3: Pass the mixed raw material prepared in S2 into the inside of the mixing tank 11 in the pulping ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com