Double-motor rotor structure

A rotor structure, dual motor technology, applied in the direction of electric components, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems of layout interference, loss, large size of a single motor, etc., to improve motor efficiency and reduce motor loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

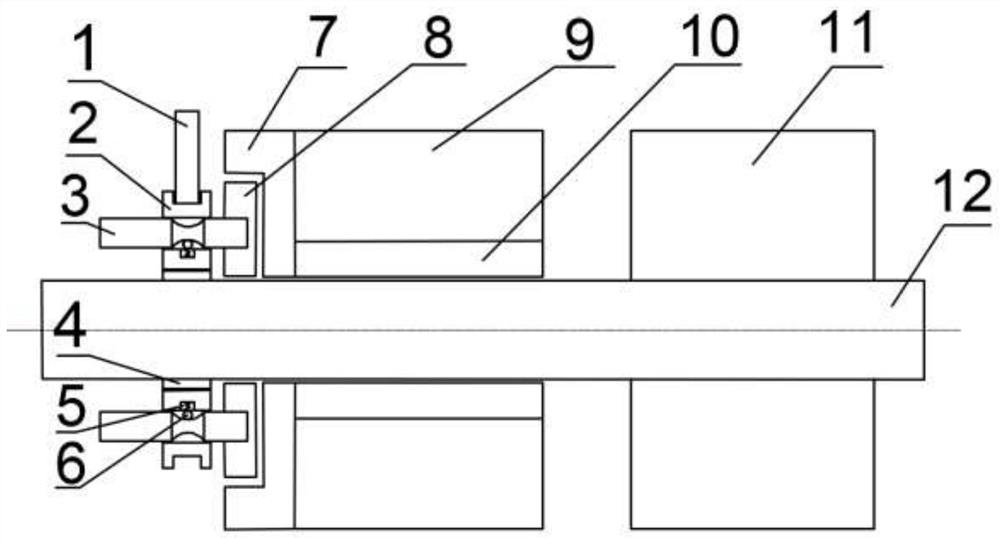

[0015] The dual-motor rotor structure of the present invention includes a lever 1, an adapter sleeve 2, a positioning pin 3, a spline hub 4, a steel ball 5, a spring 6, a friction cone 7, a friction cone 8, a first rotor core 9, a sleeve Shaft 10 , second rotor core 11 and output shaft 12 . Among them, the driving rod 1 is connected with the adapter sleeve 2, the positioning pin 3 is slidingly connected with the adapter sleeve 2, the spline hub 4 is fixed on the output shaft 12, and the steel ball 5 is pressed into the adapter sleeve 2 by the spring 6 to play a positioning role. . The friction cone ring 8 is installed on the positioning pin 3, and the friction cone ring 8 is brought into contact with the friction cone disc 7 through the dialing of the lever 1, and the friction cone disc 7 is connected with the first rotor core 9, and the sleeve shaft 10 and the The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com