Energy saving management method for motor in conveyor belt

A management method and conveyor belt technology, applied in the management field, can solve problems such as power loss and waste, and achieve the effects of energy saving, strong practicability and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

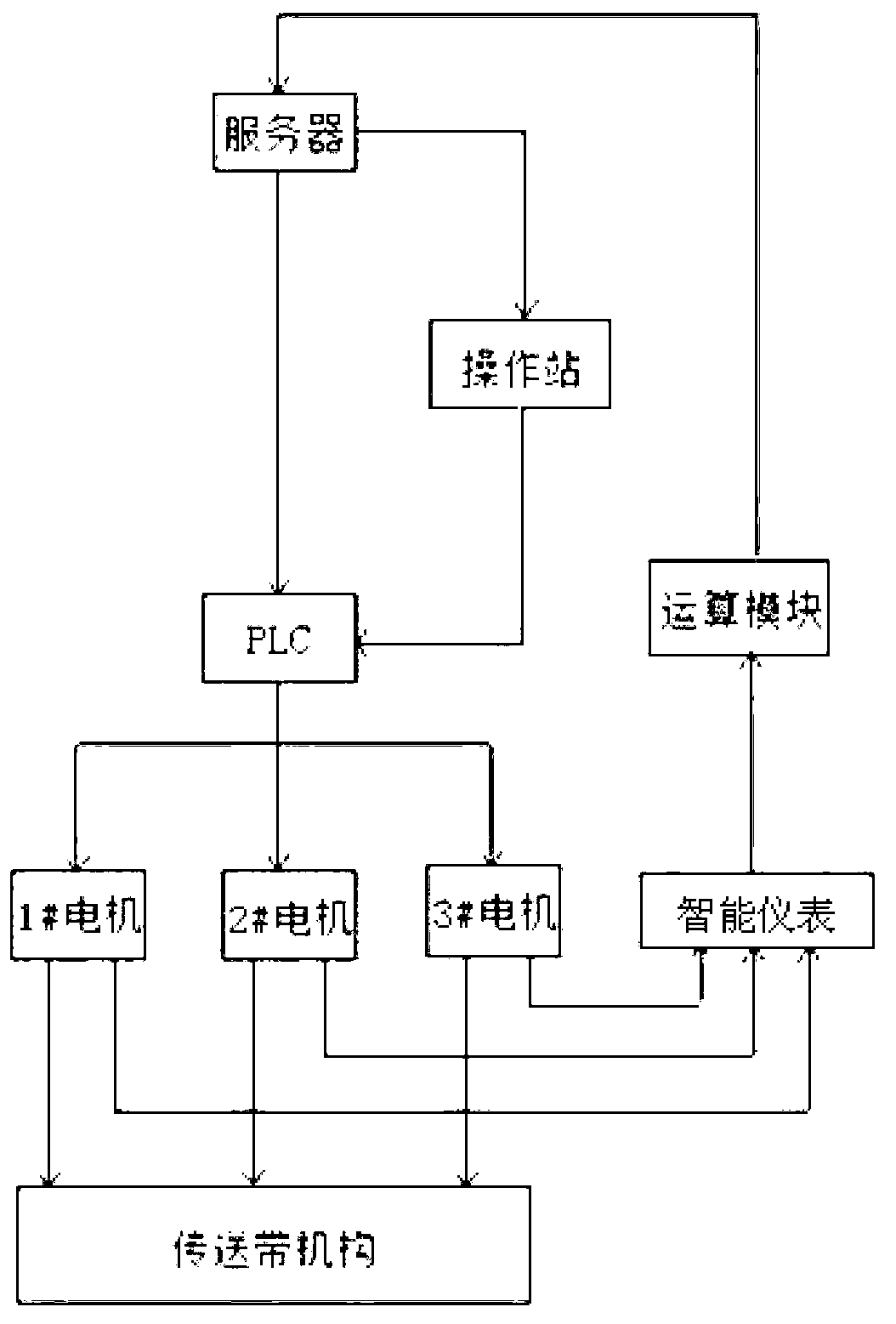

[0029] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and working principle of the energy-saving management method for the motor in the conveyor belt proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. illustrate.

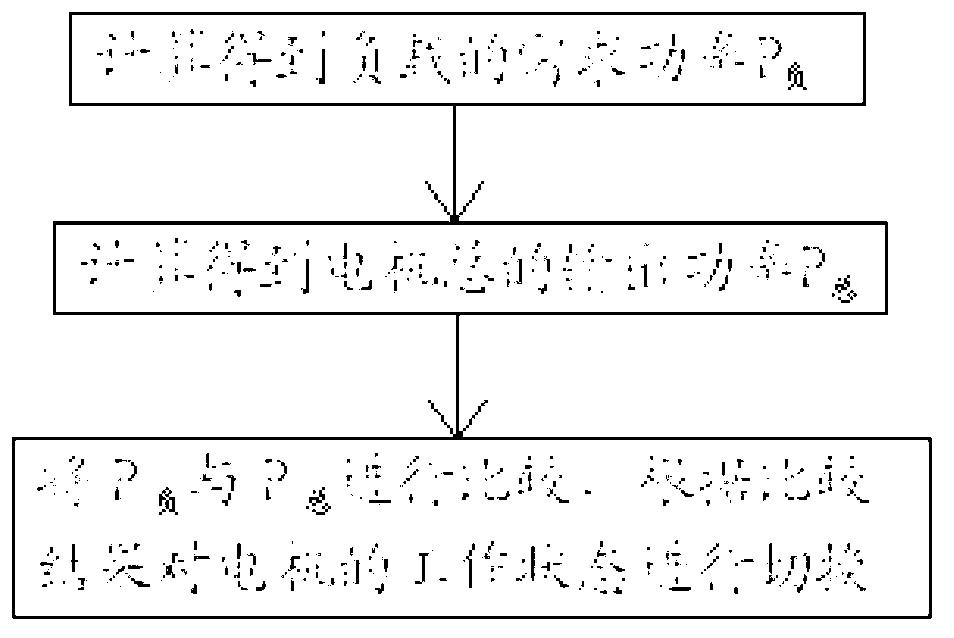

[0030] Depend on figure 1 It can be seen that the energy-saving management method of the motor in the conveyor belt provided by the present invention includes:

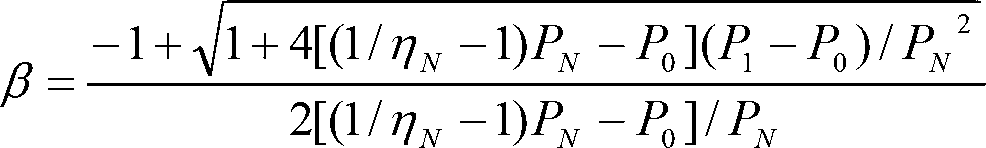

[0031] Calculate the demand power P of the load 负 ; Specifically, through the formula The required power of the load is calculated; among them, m is the mass of the load, g is the gravity coefficient, t is the time for the load to do work, and h is the height of the vertical rise of the load.

[0032] Then the output power P of the motor at no load is obtained through the smart meter 0 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com