Ultra-light low-centroid reflector flexible supporting structure of miniature space remote sensor and assembling method

A technology of mirror support and micro-space, which is applied in installation, instrumentation, optics, etc., can solve problems such as difficult to arrange support structures, affect the surface shape of the mirror, and the center of rotation and the center of mass of the mirror do not coincide, so as to avoid internal stress, Effects of reduced surface accuracy and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

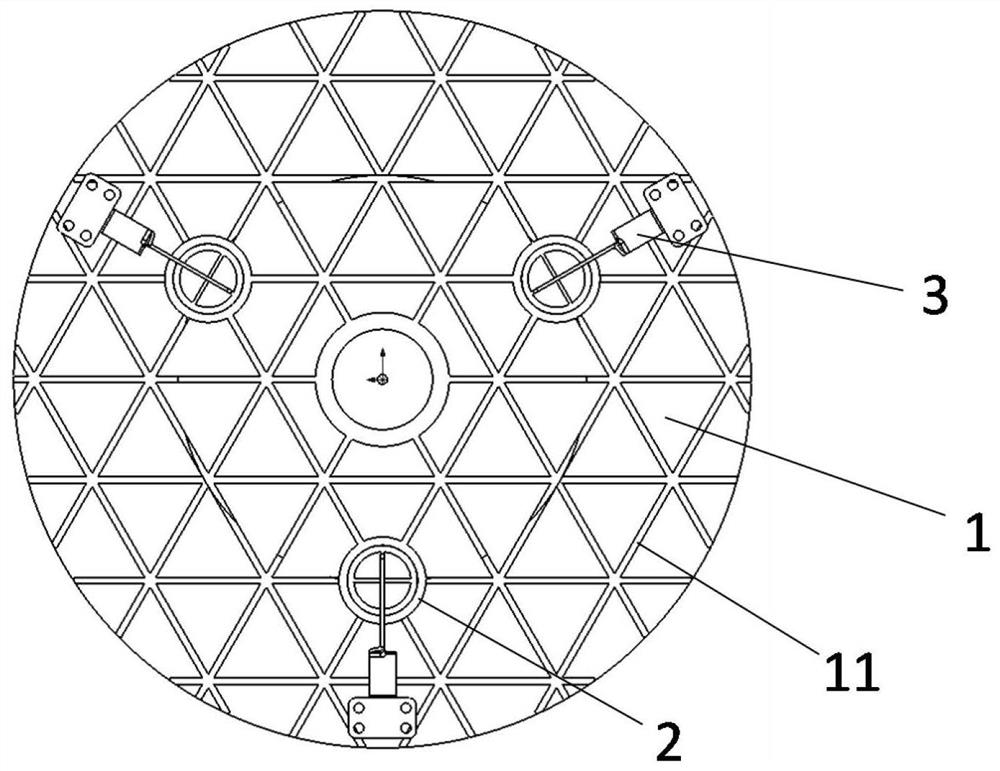

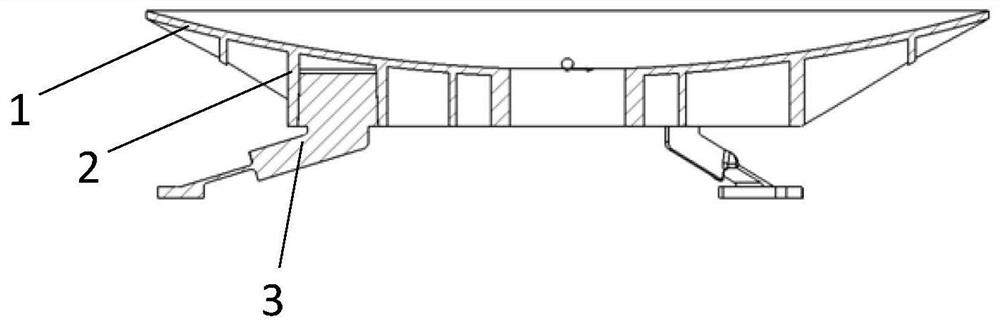

[0045]A flexible support structure for an ultra-light low-centroid reflector of a miniature space remote sensor, comprising a reflector support shell 1, the shape of the front of the reflector support shell 1 is adapted to the reflector to be supported, and the front of the reflector support shell 1 The inner diameter of the mirror is 80-400mm, which is equal to the outer diameter of the ultra-light low-centroid reflector, and also includes three reflector support hole structures 2 evenly arranged on the same circumference of the back of the reflector support shell 1 (with three 120° circles) Uniformly distributed support holes), and three integrated flexible support units 3; each flexible support unit 3 includes a mirror bonding cone ring 31, a cross support structure 32, a flexible component 33 and a substrate mounting platform 34; the reflector The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com