Vehicle synchronizer assembly and vehicle

A synchronizer and vehicle technology, which is applied to the transmission field of vehicles, can solve the problems of incomplete meshing, wear of gear sleeves and engaging teeth, etc., and achieves the effect of avoiding wear and tearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

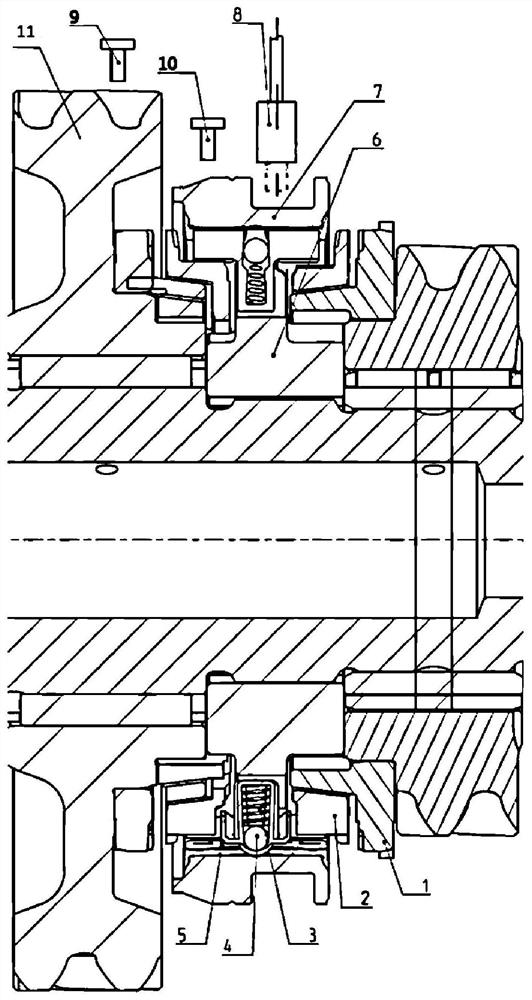

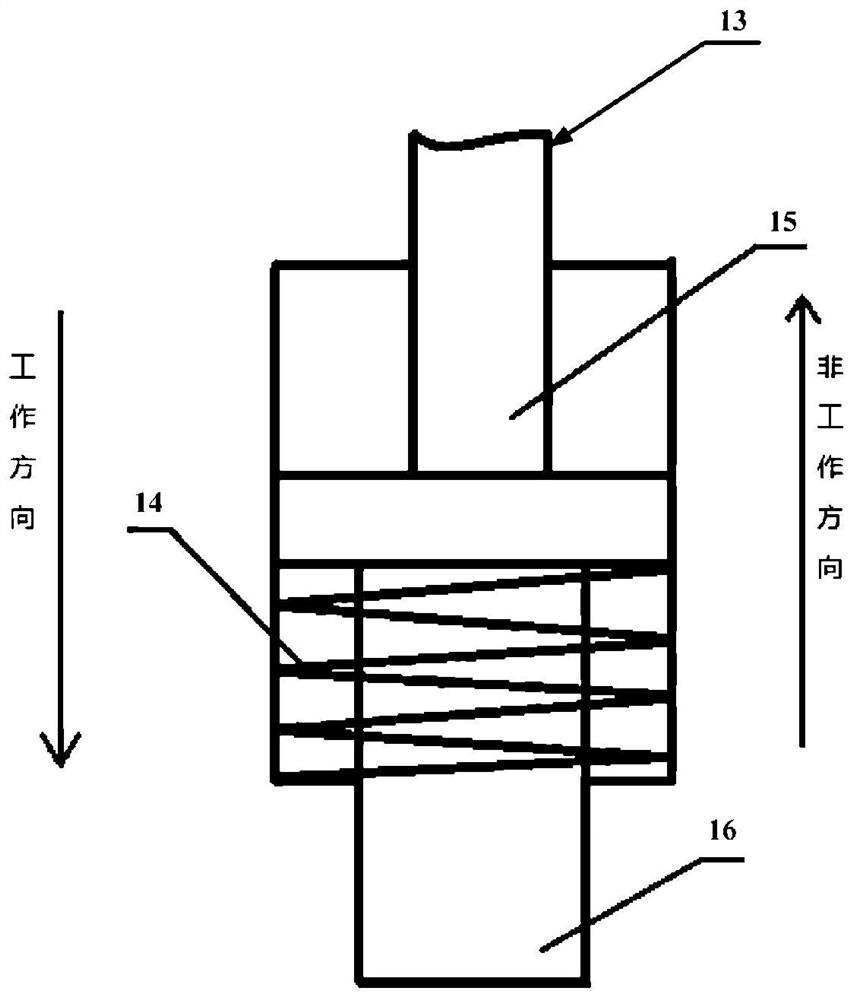

[0029] figure 1 A schematic structural diagram of a vehicle synchronizer assembly according to an embodiment of the present invention is shown. like figure 1 As shown, the vehicle synchronizer assembly generally includes a gear hub 6 , a gear sleeve 7 , a slider 5 , a synchronization ring 2 , engaging teeth, a spring 3 and a steel ball 4 . The gear hub 6 is sleeved outside the working shaft of the vehicle, and the gear sleeve 7 is sleeved outside the gear hub 6 . The gear sleeve 7 is driven by the shift fork to move axially, passes through the synchronous ring 2, and meshes with the gear gear 11 to realize shifting and transmitting torque. The synchronous ring 2 synchronizes the speed gear 11 and the gear sleeve 7 with different rotating speeds quickly before engaging the teeth through the conical surface friction pair. In order to solve the technical problem of incomplete meshing after shifting due to wear of the locking angle between the tooth sleeve 7 and the engaging to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com