Cart wheel for rail car

A technology of rail cars and pallets, which is applied in the field of wheels, can solve the problems that the wheels cannot meet the requirements of use, and achieve the effects of convenient and quick installation, reduced use costs, and light weight of the wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

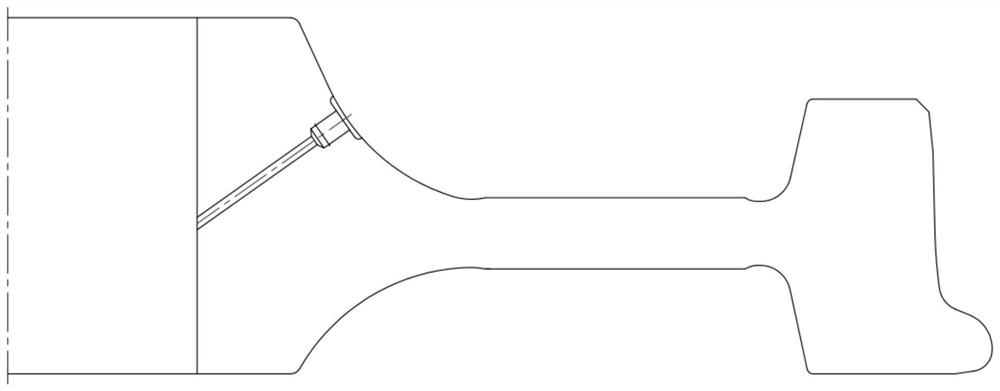

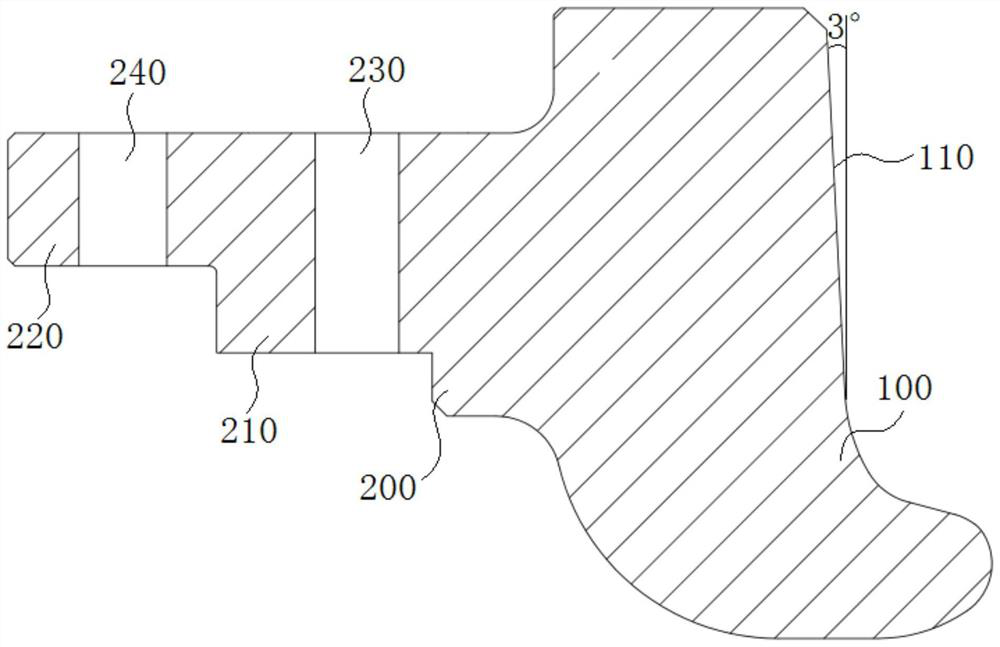

[0031] like figure 2The shown pallet wheel for rail cars includes an integrally formed rim 100 and spokes 200, the rim 100 is provided with a tread 110, the tread 110 has a certain slope, and the slope is 3°; the spoke 200 is provided with The first clamping table 210 and the second clamping table 220, the first clamping table 210 is provided with a through hole 230, and the second clamping table 220 is provided with a threaded hole 240; the rim 100 and the wheel spoke 200 are formed by adding Cr , Ni, Mo, V and Nb trace alloying elements in AARM107 / M208 standard C grade steel, oxygen content below 15ppm. The wheel has a double clamping table, which can be matched with the flange on the axle, and then fixed by threaded holes and through holes 230 through bolts.

[0032] The effect of the above scheme is described. There is a correlation between the slope of the tread surface 110 and the rolling life, and as the slope increases, the rolling life decreases. As a result of te...

Embodiment 2

[0041] It is basically the same as Example 1, except that the added mass fractions of the trace alloying elements according to the total mass of the wheel are Cr: 0.18%, Ni: 0.15%, Mo: 0.05%, V: 0.01% and Nb: 0.35 %.

Embodiment 3

[0043] It is basically the same as Example 1, except that the added mass fraction of the trace alloying elements according to the total mass of the wheel is Cr: 0.25%, Ni: 0.15%, Mo: 0.10%, V: 0.04% and Nb: 0.15 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com