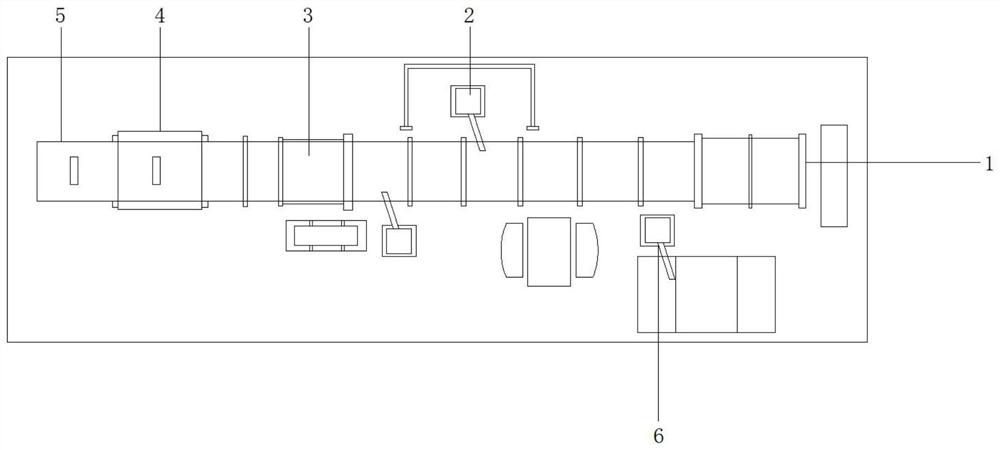

Novel full-automatic door body glue injection production line

A fully automatic, production line technology, applied to the surface coating liquid device, coating, etc., can solve the problems of low processing efficiency and cumbersome procedures of complete sets of equipment, and achieve the effects of improving efficiency, saving factory space, and simplifying management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The line body adopts the tooling mold floating production method. When changing the model, you only need to transfer the corresponding tooling mold to the mold changing station. After the change, it can be directly sent to the line body to participate in production. The production process is as follows: Manually install two door frames at the same time, press the button, automatically clamp the door frame----clamping and holding, transport to the gluing station-----clamping and holding, robot automatic gluing----- Clamping and holding, - conveying to the glass placing station, manually placing the glass---clamping and holding, conveying to the pressing station, holding pressure for 10 seconds------clamping and holding, conveying 10 work Position----clamping and holding, conveying to the door removal station, automatic release of the clamping, automatic door removal, and taking the door to the final assembly line for final assembly----the loosened tooling board is automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com