Recycling and screening device

A screening device and box technology, applied in magnetic separation, solid separation, grain processing, etc., can solve problems such as surplus transportation space, environmental impact of waste plastics, waste plastics cannot be shredded, etc., to save costs and realize resource reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

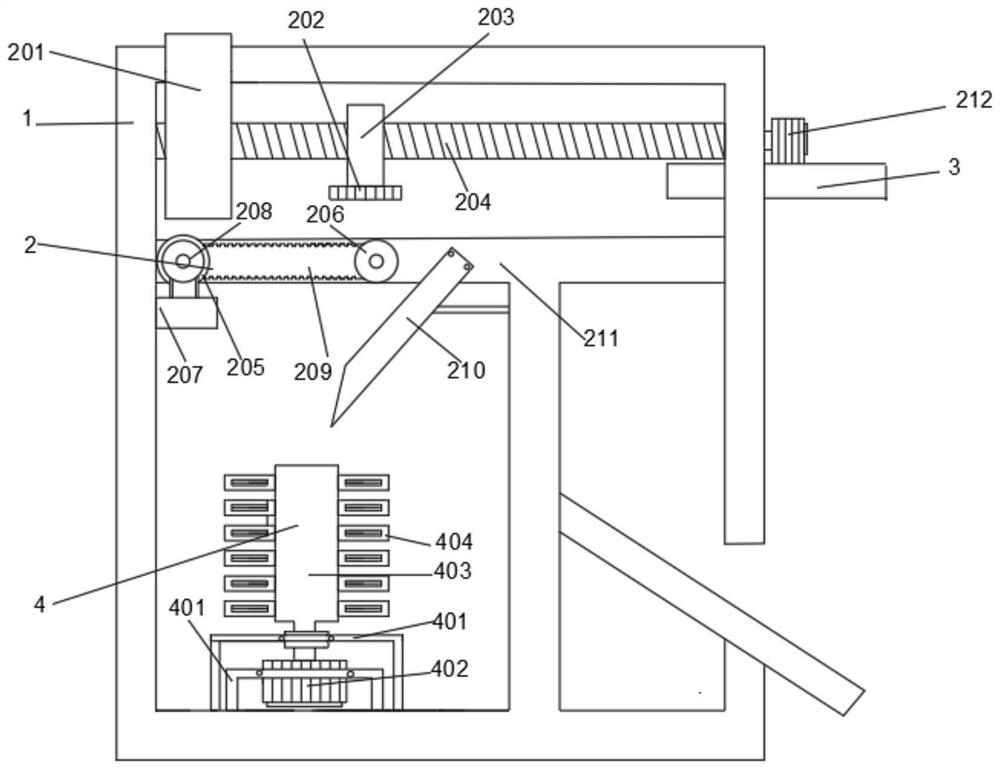

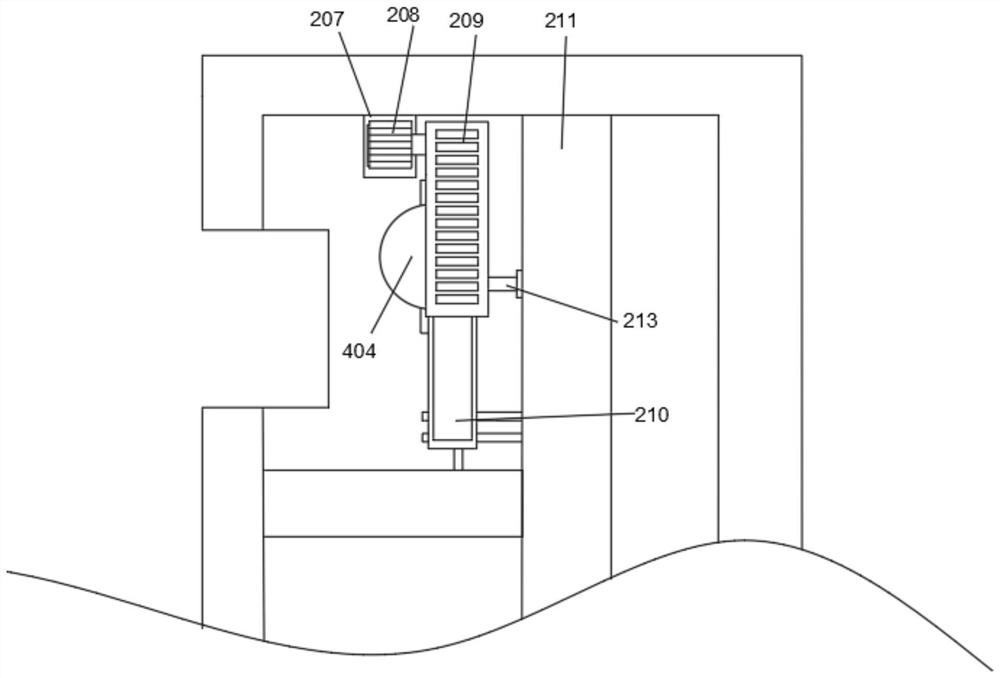

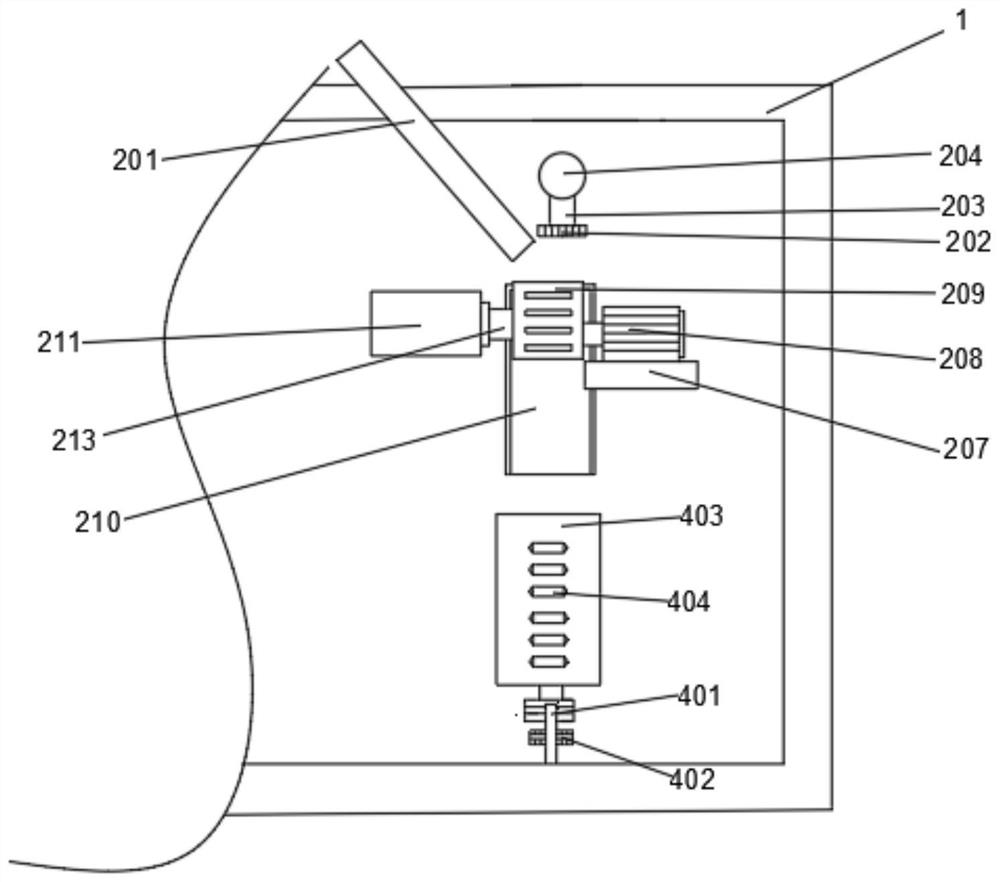

[0023] Example 1, such as Figure 1-3 As shown, the present invention provides: a recycling screening device, comprising a box body 1, the inside of the box body 1 near the top is provided with a screening mechanism 2, the outer wall on the right side of the box body 1 near the top is fixedly embedded with a support plate 3, the box body 1 The inner surface of the left side is provided with a mincing mechanism 4 .

[0024] Let's talk about the specific settings and effects of the screening mechanism 2 and the crushing mechanism 4 below.

[0025] Such as figure 1 and figure 2 As shown, the screening mechanism 2 includes a feed pipeline 201, the feed pipeline 201 is fixedly installed on the top of the left side of the box body 1, the top of the support plate 3 is fixedly connected with a first DC motor 212, and the right side of the box body 1 is close to the center. The inner wall is fixedly connected with a support block 207, the top of the support block 207 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com