Battery module and battery pack

A technology for battery modules and cell packs, applied in battery pack components, batteries, secondary batteries, etc., can solve problems such as poor use safety performance, and achieve good use safety performance, longer escape time, and delayed burning speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

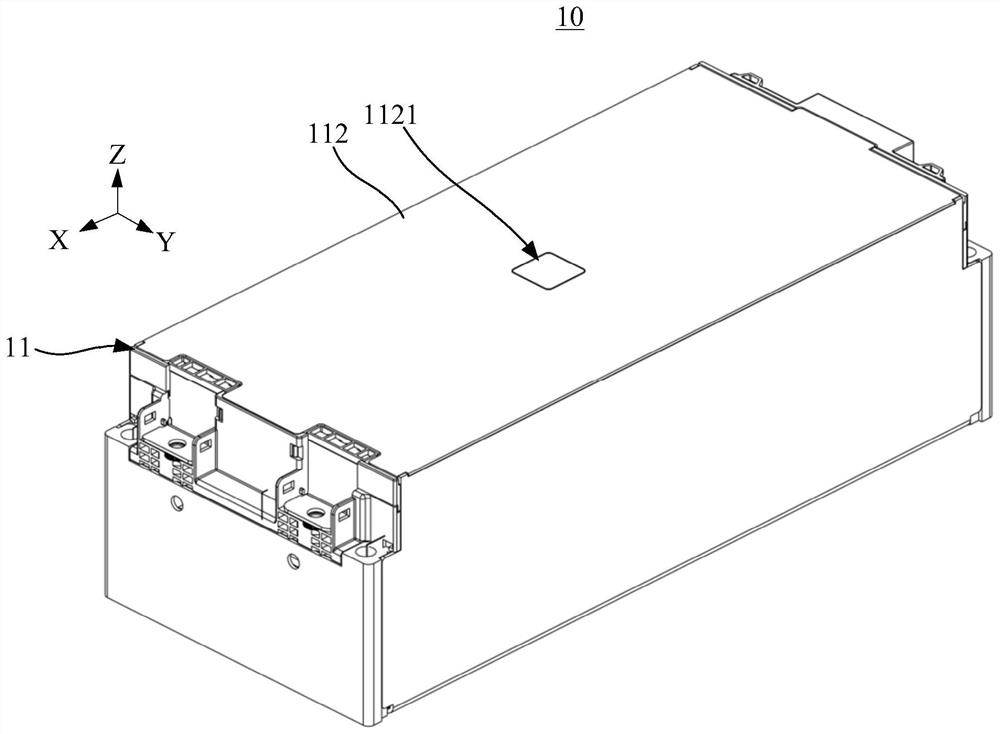

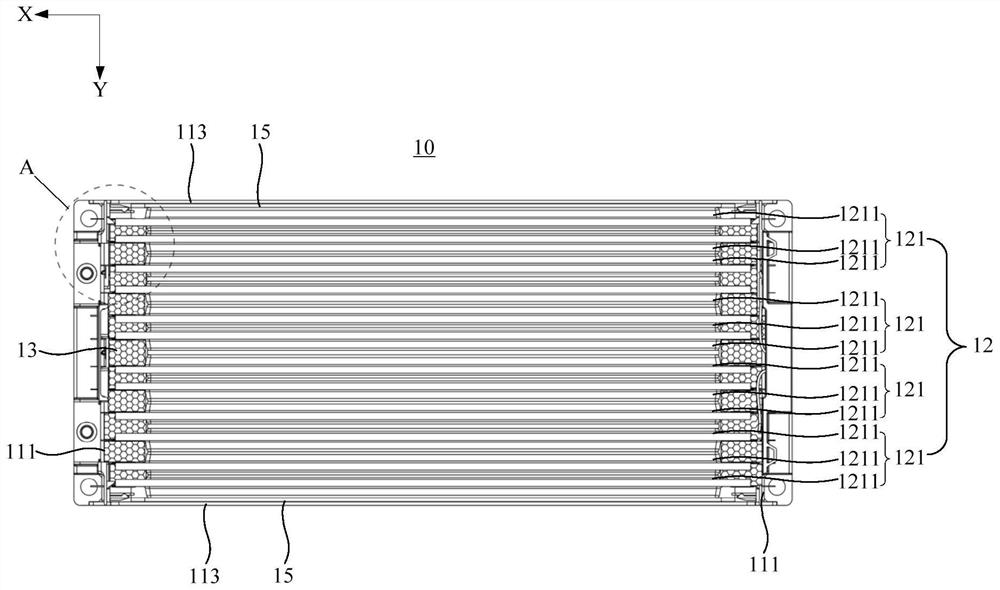

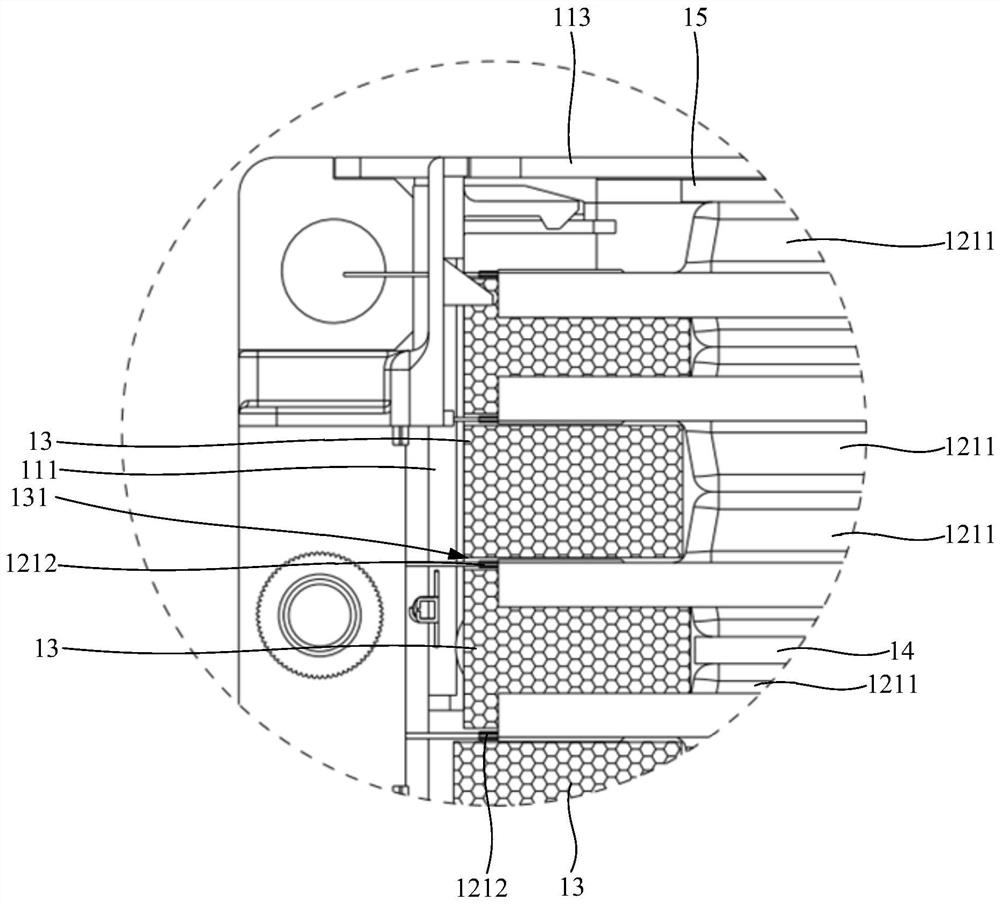

[0037] Please combine Figure 1 to Figure 4As shown, a battery module 10 includes a casing 11 and a cell group 12 disposed in the casing 11. The cell group 12 includes a plurality of cell cells 1211 stacked in sequence, and each cell cell 1211 includes a pole The ear 1214 and the cell main body 1213, the tab 1214 and the cell main body 1213 are sealed and connected to form a tab edge sealing portion 1212, the casing 11 includes a tab bracket 111 for fixing the tab 1214 of each cell unit 1211, and the battery module The group 10 also includes a plurality of fire-proof heat insulators 13 arranged in sequence along the stacking direction of the battery cells 1211, and each fire-proof heat insulator 13 abuts against the lug bracket 111 and the battery cell of the corresponding battery cell 1211 Between the main bodies 1213 and between two adjacent fireproof heat insulators 13 is formed a heat insulation gap 131 for inserting the lug sealing portion 1212 of the corresponding cell u...

Embodiment 2

[0047] Compared with the first embodiment, the present embodiment differs in that the types of the fireproof heat insulator 13 are different.

[0048] In this embodiment, the fireproof heat insulator 13 is a foamed fireproof heat insulator. After the battery module 10 is assembled, foam material is filled in the gap between the tab edge sealing parts 1212 of two adjacent battery cells 1211. After the foaming material is solidified, the above-mentioned fireproof heat insulator 13 is formed to close the gap between the tab edge sealing parts 1212 of two adjacent battery cells 1211. When the battery cells 1211 in the battery module 10 experience thermal runaway And when the high-temperature gas or flame breaks through the lug sealing portion 1212 of the battery cells 1211 , the foam fireproof heat insulator can effectively prevent the high-temperature gas or flame from spreading along the stacking direction of the battery cells 1211 .

Embodiment 3

[0050] Compared with the first embodiment, the present embodiment differs in that the types of the fireproof heat insulator 13 are different.

[0051] In this embodiment, the fireproof heat insulator 13 is a phase change fireproof heat insulator, that is, the fireproof heat insulator 13 is made of a phase change material, such as paraffin, silicone resin or a mixture containing more than 5wt% silicone resin, the battery After the assembly of the module 10 is completed, a phase-change fire-proof heat insulator is placed in the gap between the tab edge sealing parts 1212 of two adjacent battery cells 1211. When the battery cells 1211 in the battery module 10 experience thermal runaway and When the high-temperature gas or flame breaks through the tab edge portion 1212 of the battery cell 1211, the phase-change fireproof heat insulator is heated and gradually changes from a solid state to a vapor state or a liquid state, thereby absorbing heat and effectively delaying the high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com