Rotary drying device for cleaning inner and outer rings of bearing

A technology of rotating drying, inner and outer rings, applied in the directions of drying, dryer, lighting and heating equipment, etc., can solve the problems of no obvious improvement in service life, inability to carry out effective and comprehensive drying, etc., which is conducive to popularization Use, improve speed and quality, fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

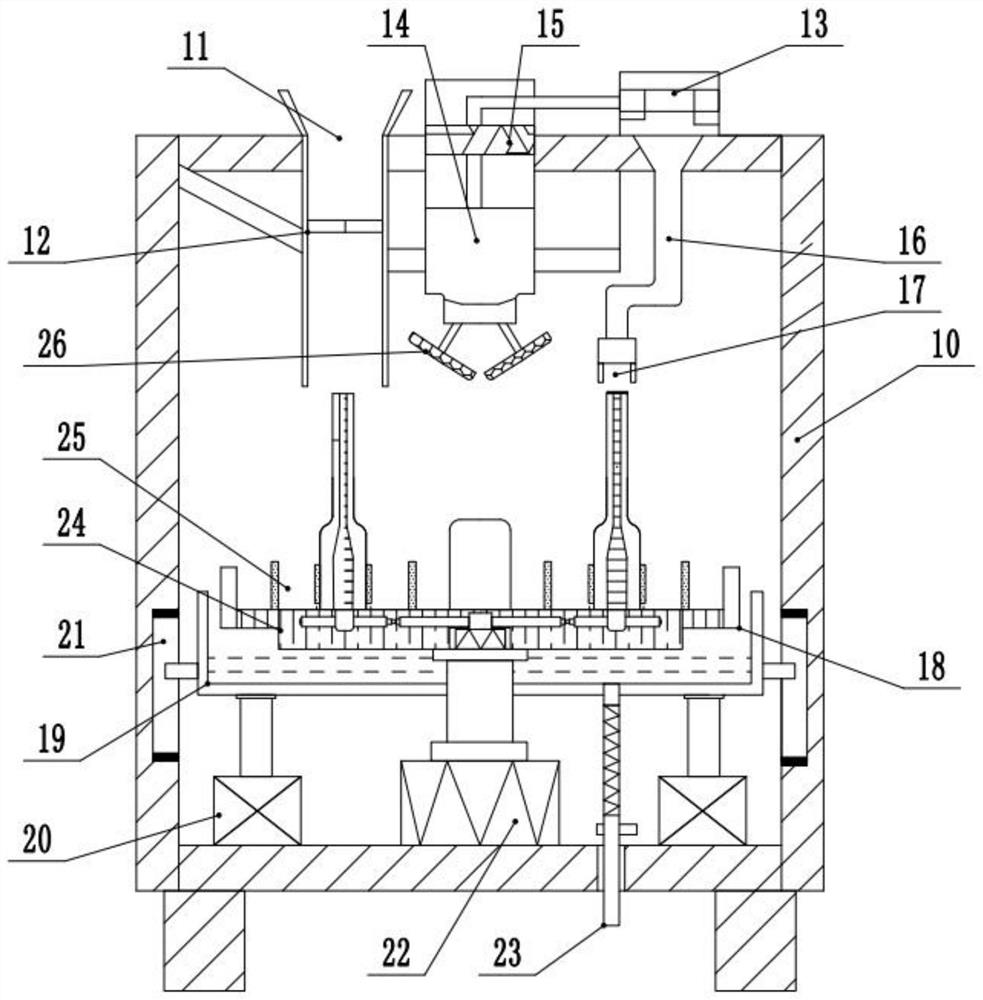

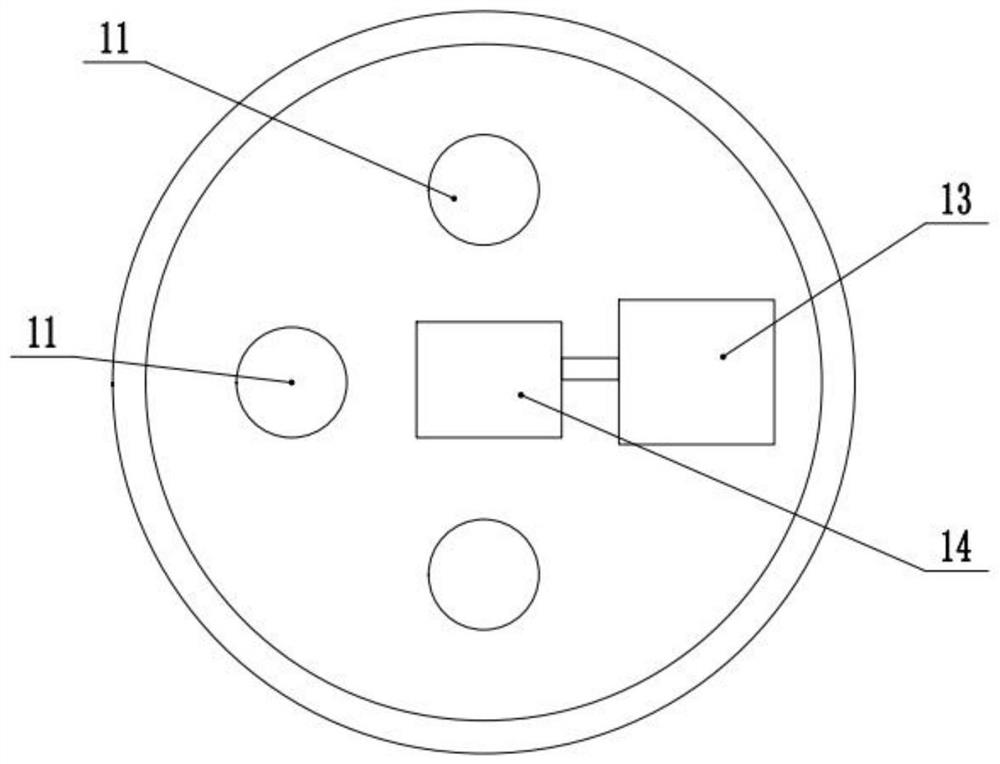

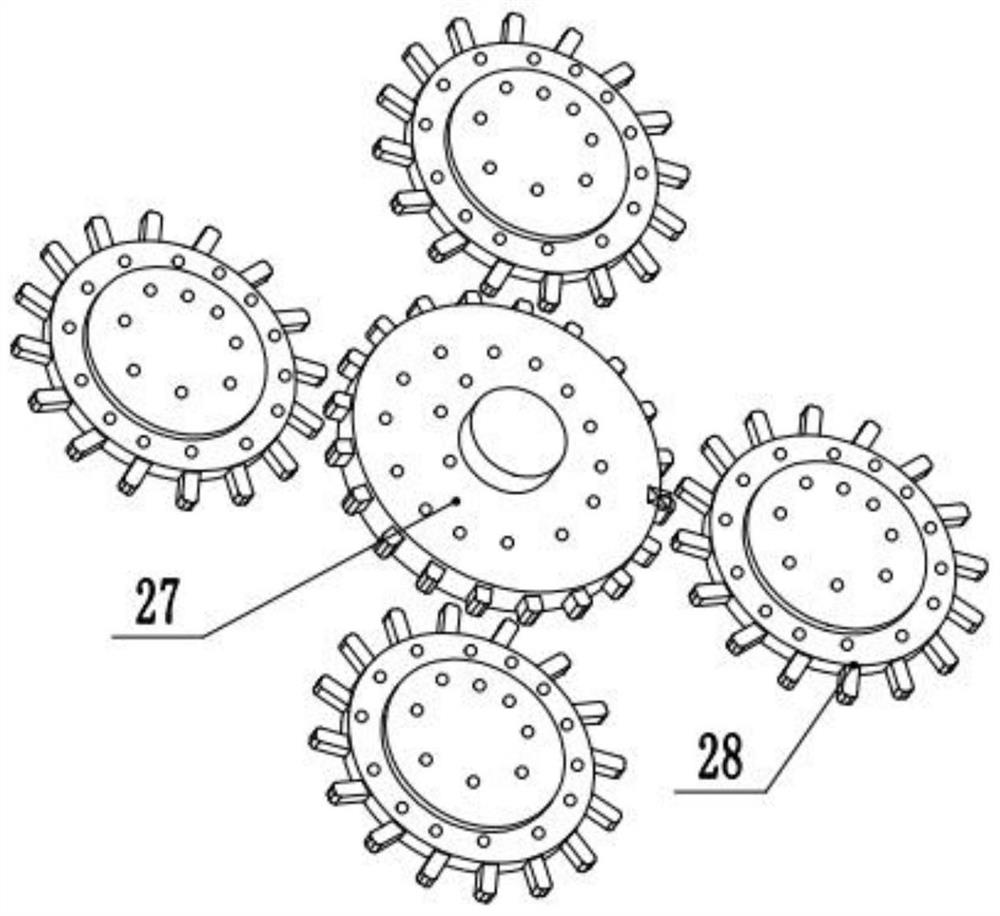

[0024] see Figure 1-5 , a bearing inner and outer ring cleaning and rotating drying equipment, including a body 10, a bearing inlet and outlet 11, a dryer 13, and a soaking pool 19; the bottom of the body 10 is fixed and supported by multiple sets of legs. Three groups of identical bearing inlets and outlets 11 are provided downwards on the top left side of the body 10 , through which the bearings to be cleaned and dried are conveniently brought into and out of the body 10 . The inner middle of the bearing inlet and outlet 11 is fixedly equipped with a left and right symmetrical opening and closing spring plate 12, and the setting of the spring plate 12 will automatically close the communication between the inside and outside of the bearing inlet and outlet 11 while not affecting the bearing in and out of the bearing inlet and outlet 11. , thereby reducing the output of the hot air inside the machine body 10 to the outside. The middle part of the body 10 is provided with a g...

Embodiment 2

[0030] On the basis of Embodiment 1, the sides of the soaking pool 19 are slidably connected in the chute 21 provided in the inner side wall of the body 10 through four groups of evenly distributed sliders, and the side walls of the soaking pool 19 are provided with sliders for sliding connection. In the chute 21, in order to increase the stability of the soaking tank 19 when lifting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com