Washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve problems such as the complexity of water inlet and exhaust pipeline systems, and achieve the effects of improving user experience, reducing noise, and avoiding electrical safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

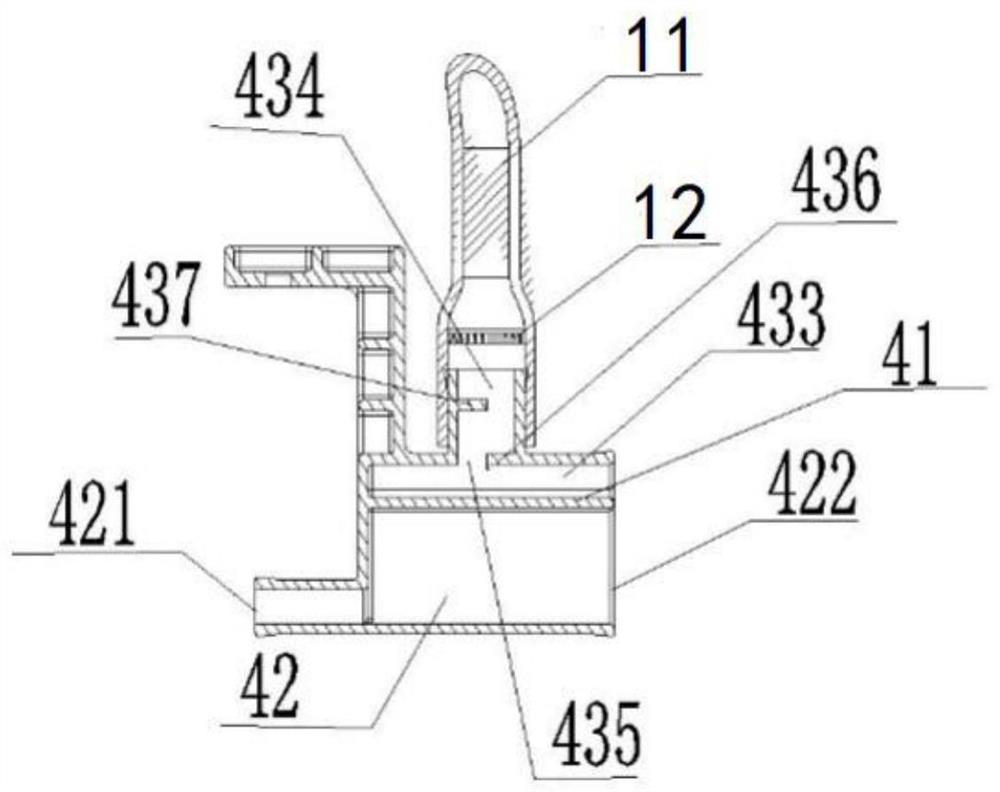

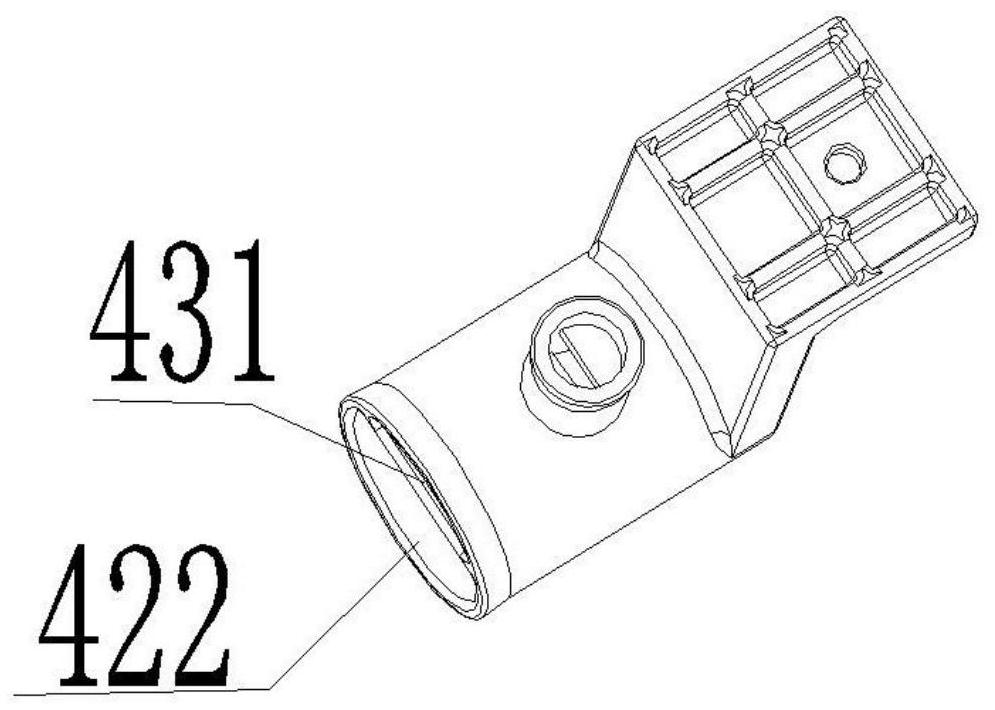

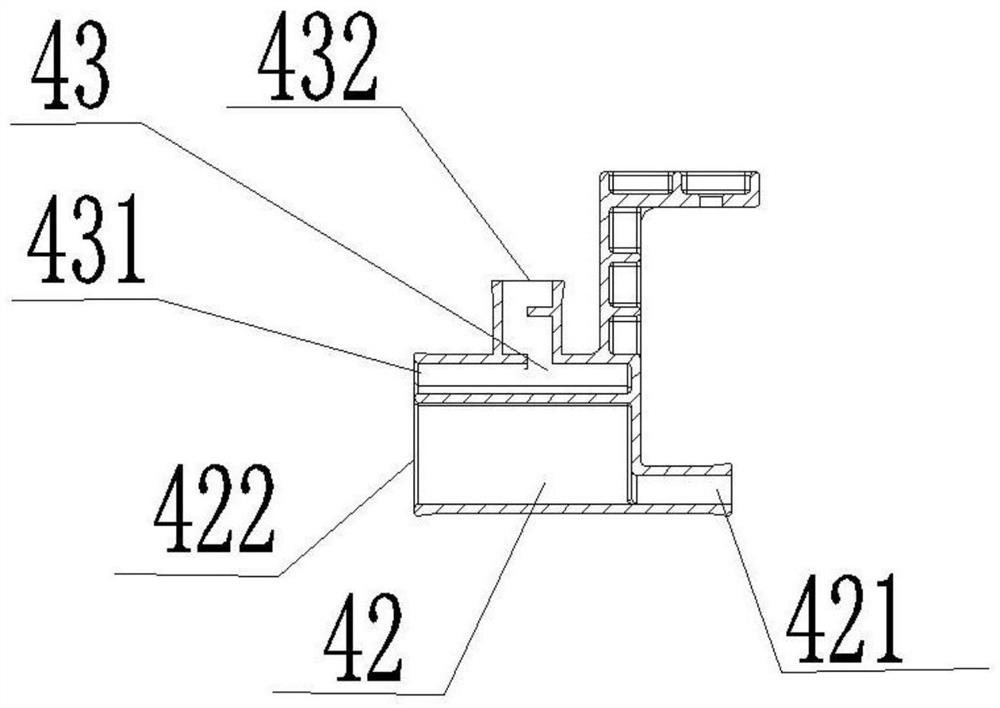

[0053] Such as Figure 1-8 As shown, this embodiment provides a washing machine, including a plurality of washing tubs, wherein at least one of the washing tubs is provided with a set of multifunctional joints 4 with water inlet and exhaust functions on the side of the water inlet 101; specifically, the multifunctional joints 4 It is provided with a liquid inlet 421, a liquid outlet 422, an air inlet 431, an exhaust port 432, and a water chamber 42 formed on the multifunctional joint 4 and internally connected to the liquid inlet 421 and the liquid outlet 422 and connected to the air inlet. 431 and the air chamber 43 of the exhaust port 432; the water chamber 42 and the air chamber 43 are independent of each other; the water inlet 101 of the washing tub is connected with the liquid outlet 422 and the air inlet 431 of the multifunctional joint 4; the liquid inlet of the multifunctional joint 4 The port 421 communicates with the water supply pipeline of the washing machine; and ...

Embodiment 2

[0068] This embodiment provides a washing machine, which includes a washing tub, and a set of multifunctional connectors 4 with water inlet and exhaust functions are arranged on the side of the water inlet 101 of the washing tub; the multifunctional connector 4 is provided with a liquid inlet 421, a liquid outlet 422, an air inlet 431, an air outlet 432, and a water cavity 42 formed on the multifunctional joint 4 and internally connected to the liquid inlet 421 and the liquid outlet 422, and an air chamber 43 connected to the air inlet 431 and the air outlet 432 The water chamber 42 and the air chamber 43 are independent of each other; the water inlet 101 of the washing bucket is connected with the liquid outlet 422 and the air inlet 431 of the multifunctional joint 4; the liquid inlet 421 of the multifunctional joint 4 is communicated with the water supply pipeline of the washing machine; The exhaust port 432 of the functional joint 4 communicates with the atmosphere or the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com