Functionalized biological hybrid micro-nano motor and preparation method thereof

A bio-hybrid, micro-nano technology, applied in the field of material technology and micro-nano manufacturing, can solve the problems of inability to solve the core driving problem of synthetic micro-nano motors, underutilization of biological entity functions, etc., and achieve uniform size and rapid detection. , the effect of enhancing magnetic responsiveness and magnetic motion control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Aiming at the problems described above in the background technology, the present invention provides a functionalized biohybrid micro-nano motor and a preparation method thereof.

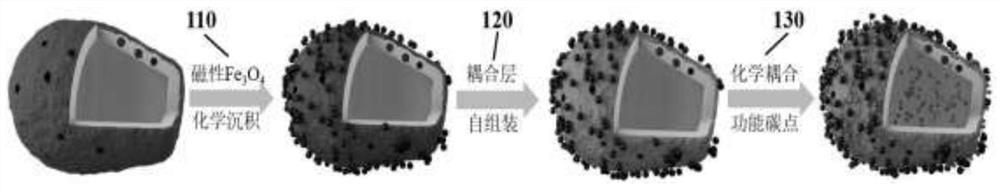

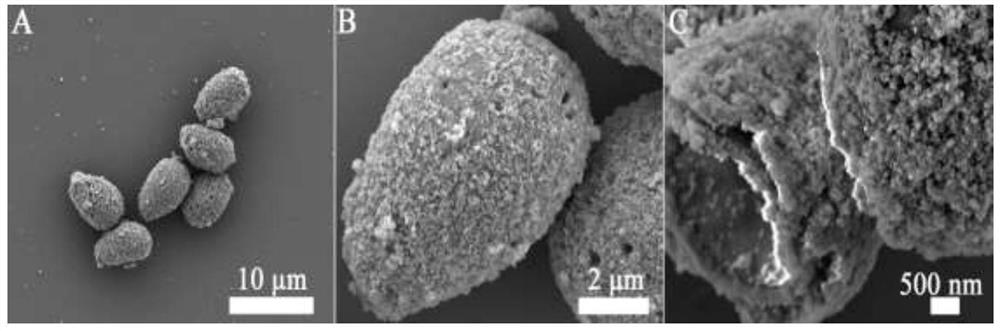

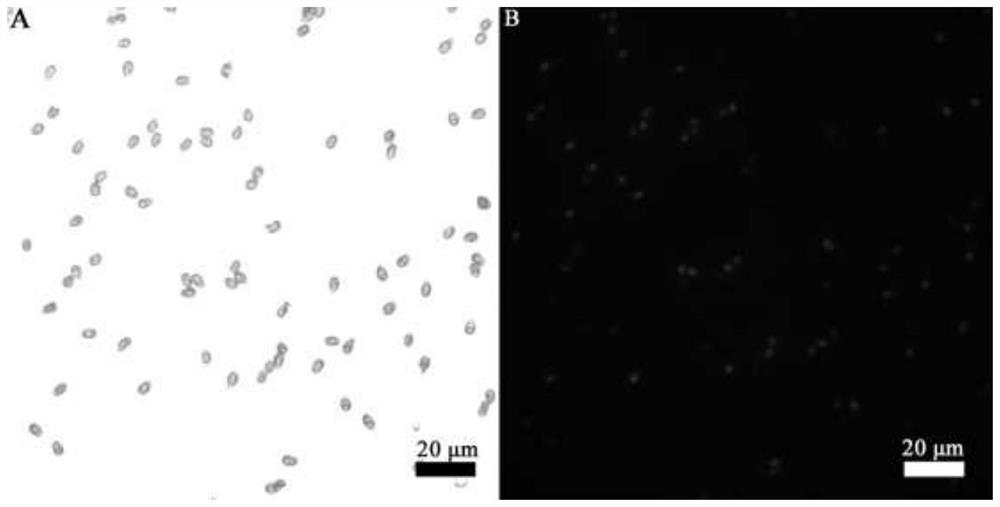

[0031] The functionalized biohybrid micro-nanomotor includes a bioentity inner core, a magnetic nanoparticle coating and a probe layer. The inner core of biological entities can be natural plant seeds, fungal spores, pollen, etc., which have unique and complex three-dimensional structures and can be cultivated or obtained in large quantities. On the surface of the inner core of the biological entity is a magnetic nanoparticle coating for micro-nanomotor drive and manipulation, which can be self-assembled by chemisorption-deposited magnetic nanoparticles. On the surface of the inner core of the biological entity wrapped by the magnetic nano-coating, there are probes immobilized by self-assembled functional groups, which include carbon dots with fluorescence emission and response capabilities an...

Embodiment

[0036] Taking the oligosaccharide-functionalized spore-based micro-nanomotor as an example, the functionalized biohybrid micro-nanomotor and its preparation method are described in detail.

[0037] Described preparation method comprises:

[0038] Step 1. Pretreatment of Ganoderma lucidum or Lycopodium spores, followed by ultrasonic treatment in 200mL absolute ethanol for 30min, ultrasonic treatment in 200mL deionized water for 10min and washing with deionized water several times to remove impurities on the outer membrane and inner core, Freeze-dried for later use.

[0039] Step 2. Ultrasonic disperse the spores pretreated in step 1 into 60 mL of deionized water, and stir for 5 min to form a brown suspension with evenly dispersed spores. Then FeSO was added to the above suspension 4 After stirring for 20 min, 20 mL of ammonia water (25%-27 wt %) was added dropwise, and the dropping time was controlled within 10 min. Following sealing and further stirring for 2 h, the black m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com