Cold-resistant antibacterial liquid cultivation fertilizer and processing method thereof

A processing method and fertilizer technology, applied in the direction of liquid fertilizer, organic fertilizer, inorganic fertilizer, etc., can solve the problems of fertilizer loss, disgusting cycle, loss, etc., and achieve the effect of cost saving, good effect and lower requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

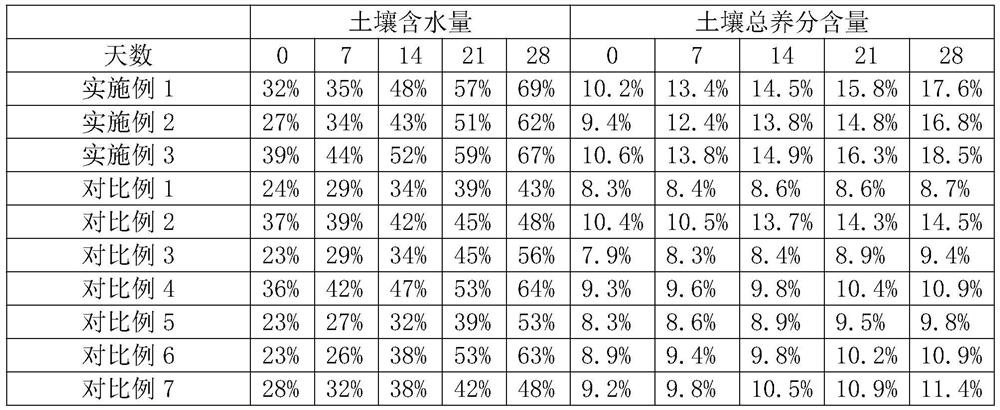

Examples

Embodiment 1

[0030] A cold-resistant and antibacterial liquid cultivation fertilizer, the raw materials of each component are as follows, in parts by weight, including 2 parts of bacterial liquid, 5 parts of deionized water, 10 parts of mineral components, 3 parts of suspension, 1 part of antifreeze, chelating agent 1 part of mixture, 2 parts of dimethyl oxalate, 5 parts of dodecylbenzene.

[0031] The raw materials of each component of the suspension are as follows, in parts by weight, including 2 parts of straw and 2 parts of cow manure.

[0032] The raw materials of each component of the mineral component are as follows, in parts by weight, including 2 parts of potassium chloride and 2 parts of phosphate rock powder.

[0033] The raw materials of each component of the chelating agent are as follows, in parts by weight, including 2 parts of calcium sodium edetate and 2 parts of xanthate.

[0034] The antifreezing agent includes one or more of 3 parts of methanol and 2 parts of propylene...

Embodiment 2

[0046] A cold-resistant and antibacterial liquid cultivation fertilizer, the raw materials of each component are as follows, in parts by weight, including 3 parts of bacterial liquid, 6 parts of deionized water, 13 parts of mineral components, 4 parts of suspension, 2 parts of antifreeze, chelating agent 2 parts of mixture, 3 parts of dimethyl oxalate, 6 parts of dodecylbenzene.

[0047] The raw materials of each component of the suspension are as follows, in parts by weight, including 3 parts of straw and 3 parts of cow manure.

[0048] The raw materials of each component of the mineral component are as follows, in parts by weight, including 3 parts of potassium chloride and 3 parts of phosphate rock powder.

[0049] The raw materials of each component of the chelating agent are as follows, in parts by weight, including 3 parts of calcium sodium edetate and 3 parts of xanthate.

[0050] The antifreezing agent includes one or more of 3 parts of glycerin and 2 parts of propyle...

Embodiment 3

[0062] A cold-resistant and antibacterial liquid cultivation fertilizer, the raw materials of each component are as follows, in parts by weight, including 4 parts of bacterial liquid, 7 parts of deionized water, 15 parts of mineral components, 5 parts of suspension, 3 parts of antifreeze, chelate 3 parts of mixture, 4 parts of dimethyl oxalate, 7 parts of dodecylbenzene.

[0063] The raw materials of each component of the suspension are as follows, in parts by weight, including 4 parts of straw and 4 parts of cow manure.

[0064] The raw materials of each component of the mineral component are as follows, in parts by weight, including 4 parts of potassium chloride and 4 parts of phosphate rock powder.

[0065] The raw materials of each component of the chelating agent are as follows, in parts by weight, including 4 parts of calcium sodium edetate and 4 parts of xanthate.

[0066] The antifreeze includes 3 parts of glycerin and 2 parts of methanol.

[0067] The raw materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com