Marking device with cargo lifting mechanism for logistics distribution

A technology of logistics distribution and conveying mechanism, which is applied to printing devices, typewriters, conveyor objects, etc., can solve the problems of large workload of workers, reduce marking efficiency, and increase manual operations, so as to reduce handling and improve marking quality. and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

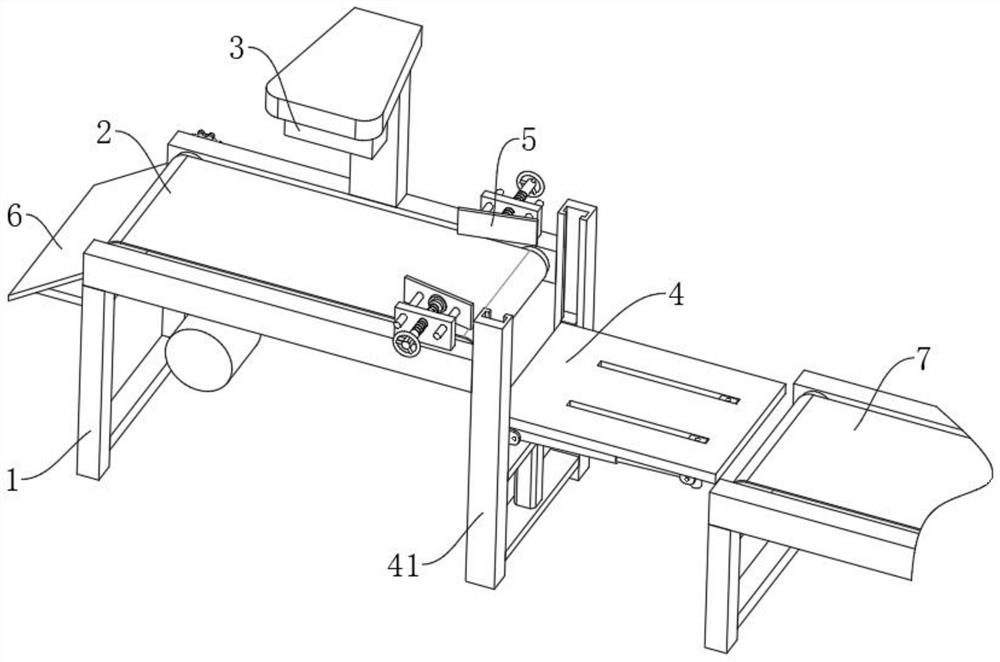

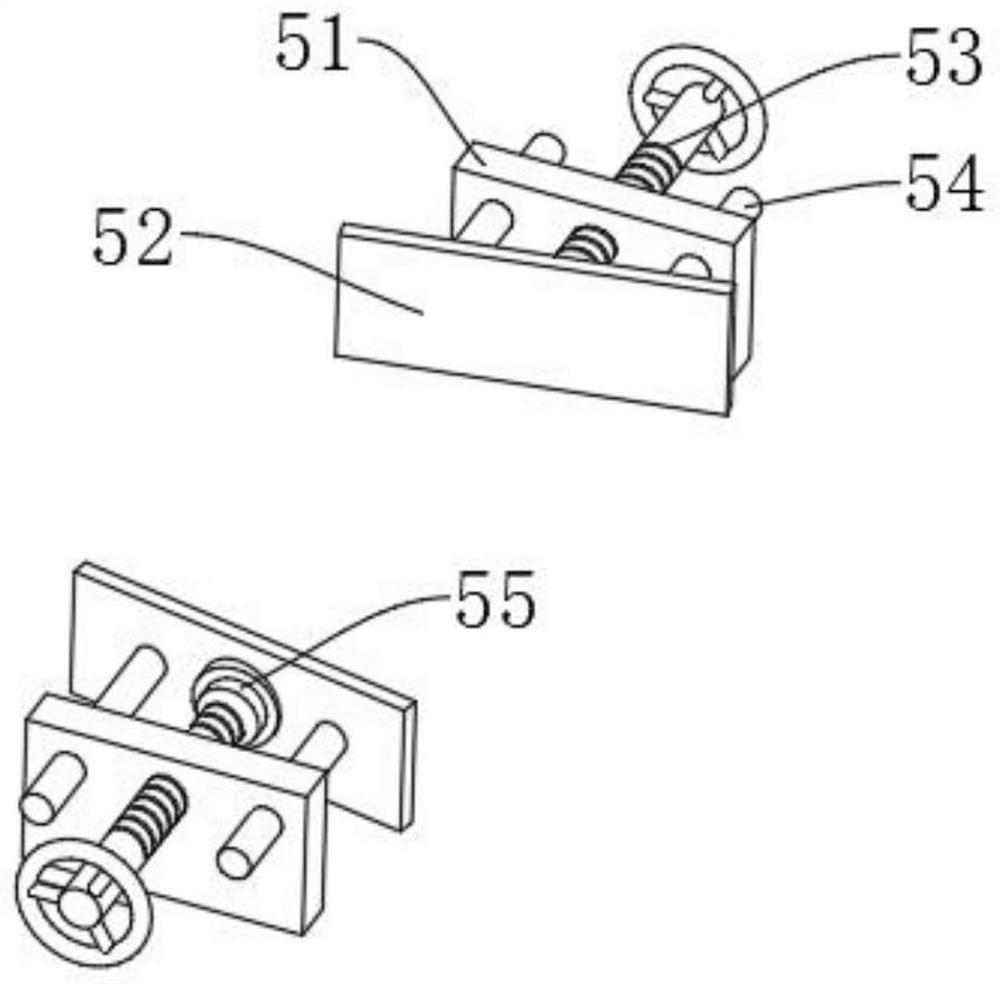

[0044] Such as Figure 1-Figure 7 As shown, a marking device with a cargo lifting mechanism for logistics distribution includes a bracket 1, a conveying mechanism 2 arranged on the bracket 1, a marking machine 3 is arranged above the conveying mechanism 2, and a marking machine 3 arranged on the conveying mechanism 2 is also included. The lifting mechanism 4 on the side for lifting the goods, and the centering mechanism 5 arranged on the side of the lifting mechanism 4 for centering the goods, the lifting mechanism 4 and the centering mechanism 5 are connected to the bracket 1;

[0045]Conveyor mechanism 2 comprises driving roller 21, and driving roller 21 side is provided with auxiliary roller 23, and driving roller 21 passes support 1, and driving roller 21 lower side is provided with driving motor 22, and driving motor 22 output ends and driving roller 21 rear ends are connected. A sprocket 25 is provided, and a conveyor belt 24 is provided on the outer ring of the driving ...

Embodiment 2

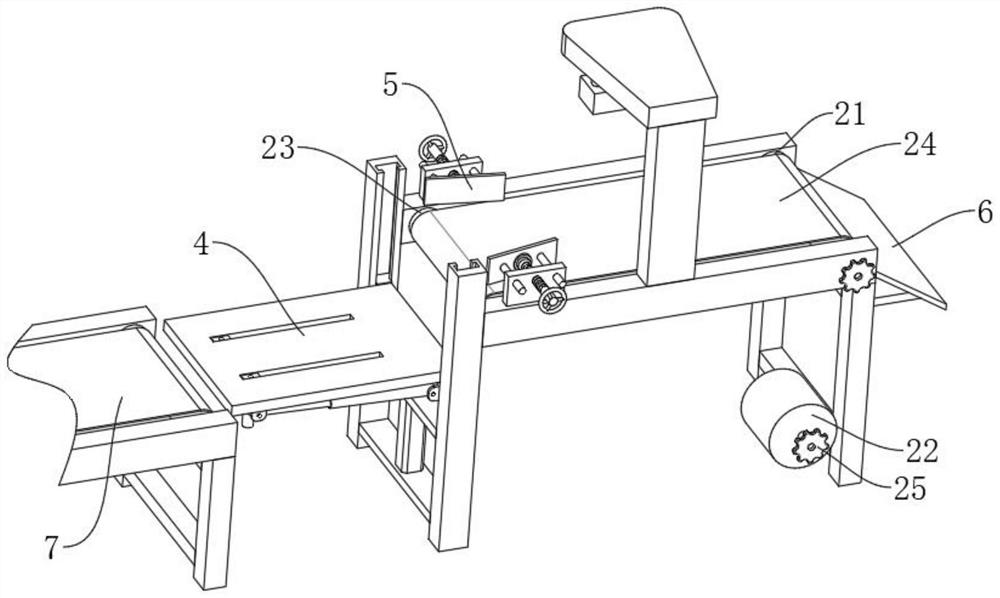

[0049] Such as Figure 4-Figure 9 As shown, a marking device with a cargo lifting mechanism for logistics distribution includes a bracket 1, a conveying mechanism 2 arranged on the bracket 1, a marking machine 3 is arranged above the conveying mechanism 2, and a marking machine 3 arranged on the conveying mechanism 2 is also included. The lifting mechanism 4 on the side for lifting the goods, and the centering mechanism 5 arranged on the side of the lifting mechanism 4 for centering the goods, the lifting mechanism 4 and the centering mechanism 5 are connected to the bracket 1;

[0050] Conveyor mechanism 2 comprises driving roller 21, and driving roller 21 side is provided with auxiliary roller 23, and driving roller 21 passes support 1, and driving roller 21 lower side is provided with driving motor 22, and driving motor 22 output ends and driving roller 21 rear ends are connected. A sprocket 25 is provided, and a conveyor belt 24 is provided on the outer ring of the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com