Sewer grating plate carrying device for municipal engineering

A technology for handling devices and gratings, applied in transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve problems such as easy shaking or falling, troublesome handling, and affecting the installation progress of sewer gratings, etc., to achieve convenience Adjust the position of the grid plate body to facilitate the effect of blessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

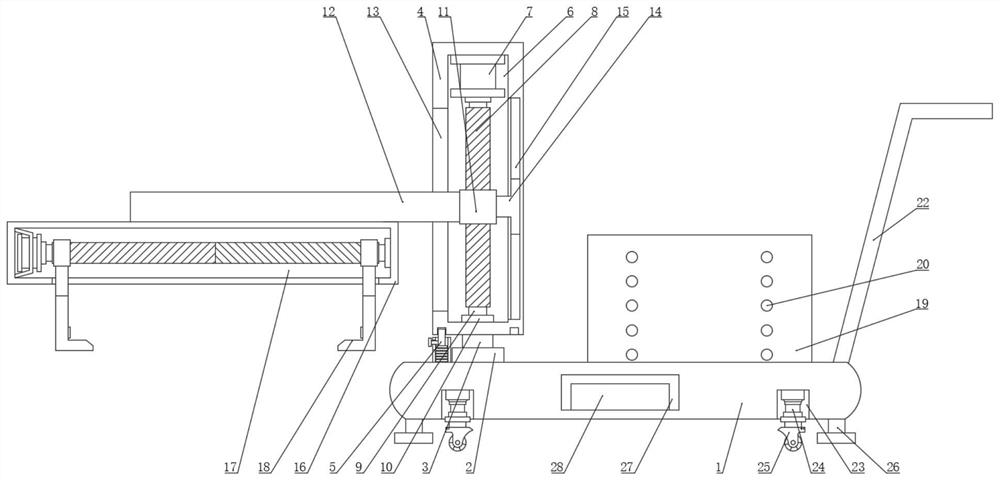

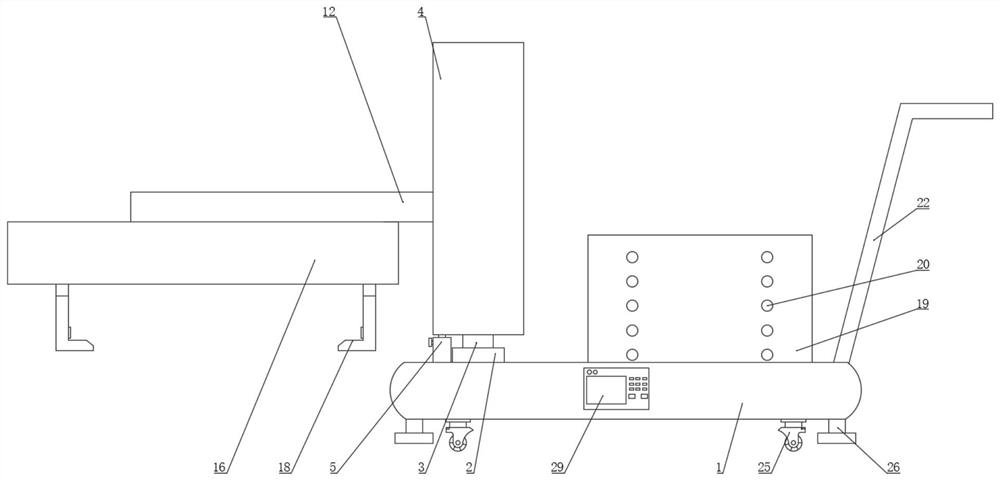

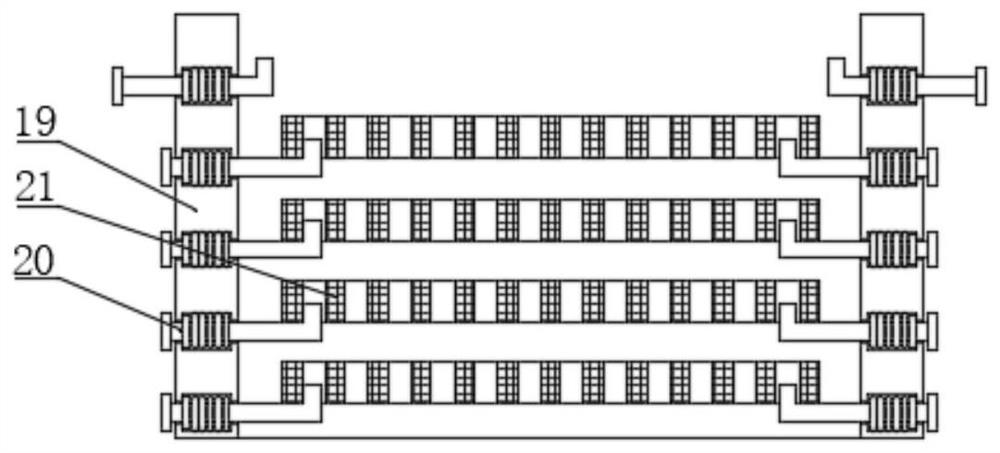

[0027] see Figure 1-7, the present invention provides the following technical solutions: a sewer grating handling device for municipal engineering, comprising a base 1, a first bearing 2 and a first rotating shaft 3, the first bearing 2 is fixedly connected to the upper surface of the base 1, and the first rotating shaft 3 The lower end is installed inside the first bearing 2, the upper end of the first rotating shaft 3 is fixedly connected with the first housing 4, the upper surface of the base 1 is fixedly connected with the limit assembly 5, and the limit assembly 5 is clamped on the lower surface of the first shell 4, The inside of the first housing 4 is provided with a first transmission chamber 6, the inner wall of the first transmission chamber 6 is fixedly connected with a first motor 7, the output shaft of the first motor 7 is fixedly connected with a first threaded column 8, and the lower end of the first threaded column 8 The second rotating shaft 9 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com