Clamping Flatbed Handling Manipulator

A manipulator and clamping technology, applied in the field of manipulators, can solve the problems of large-size flat products that do not conform to ergonomics, manual handling cannot meet production needs, and the operation of the conveying platform is not smooth, so as to achieve increased rigidity, reliable performance, The effect of low manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

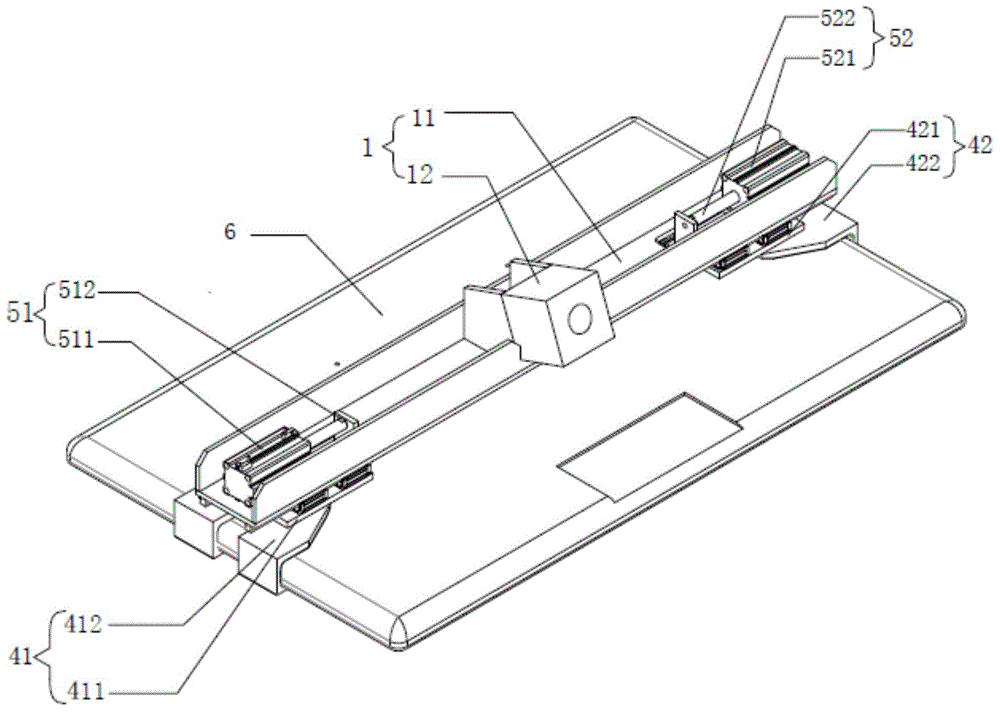

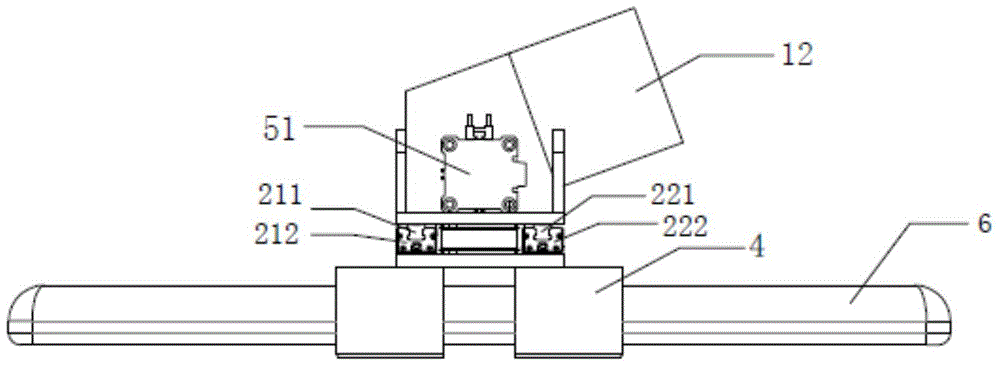

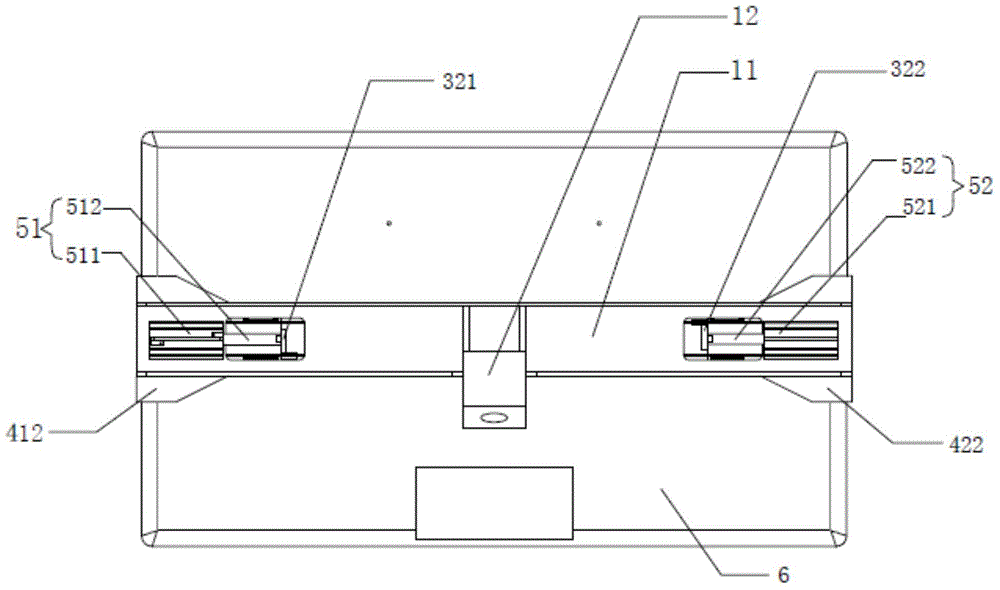

[0025] Such as Figure 1-5 As shown, the clamping type plate handling manipulator provided by the present invention includes a bracket 1, and the bracket 1 includes a crossbeam 11 and a fixing member 12 arranged in the middle of the crossbeam 11, and the section of the crossbeam 11 perpendicular to the length direction is "U". ” shape, the beam 11 includes a strip-shaped bottom groove and two sides perpendicular to the bottom groove and parallel to each other; the left and right sides of the bottom groove of the beam 11 are symmetrically provided with a rectangular installation groove 111 and an installation groove 112. Since the beam 11 adopts a "U"-shaped structure in section, the beam 11 is not easily deformed during work, and its load-bearing capacity is enhanced.

[0026] The clamping flat plate handling manipulator also includes a guide rail slider group, the above guide rail slider group is composed of at least four guide rail sliders: the first guide rail slider 21, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com