Metal surface highlight drilling and cutting device

A metal surface, drilling and cutting technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as debris splashing and poor protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

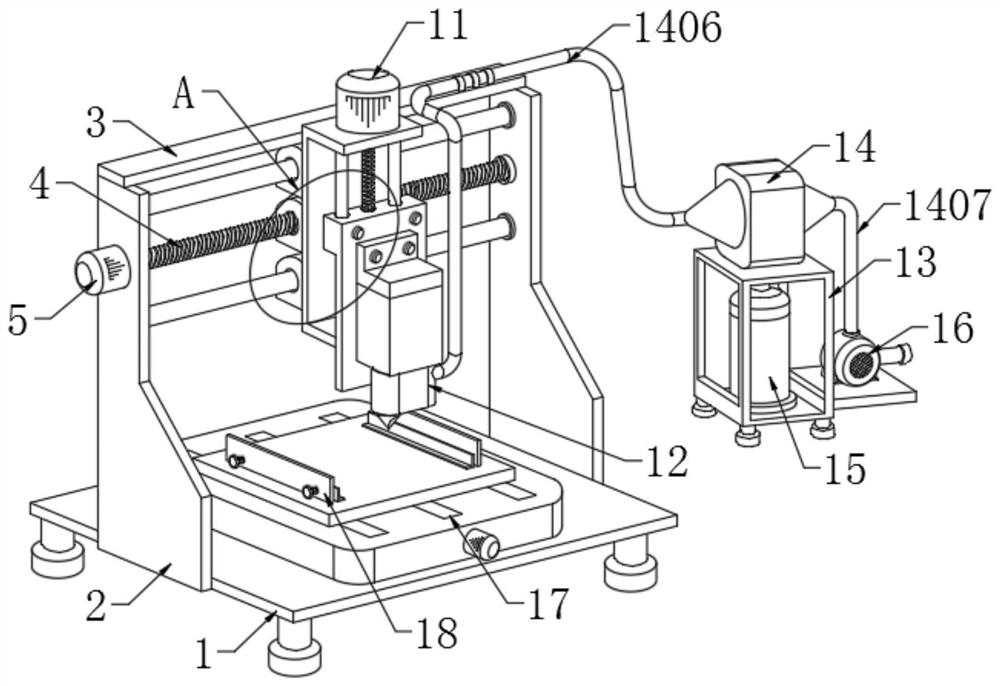

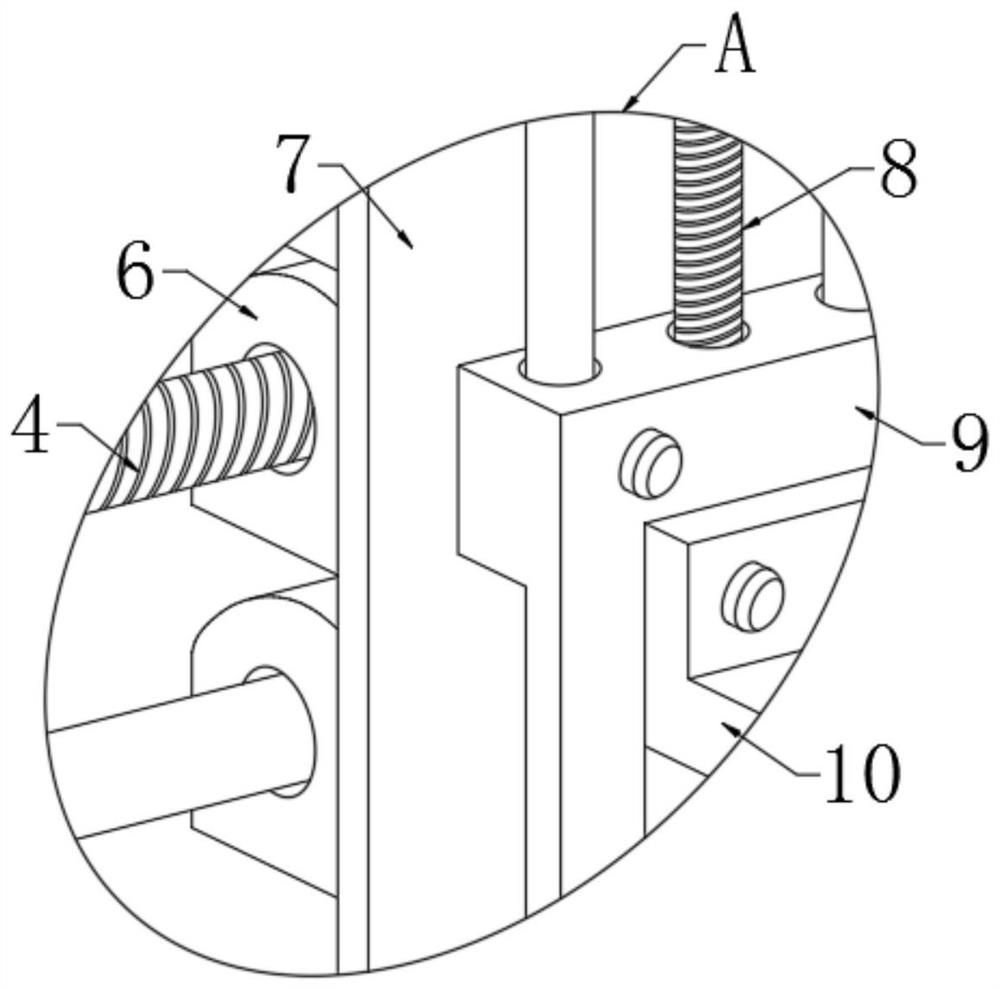

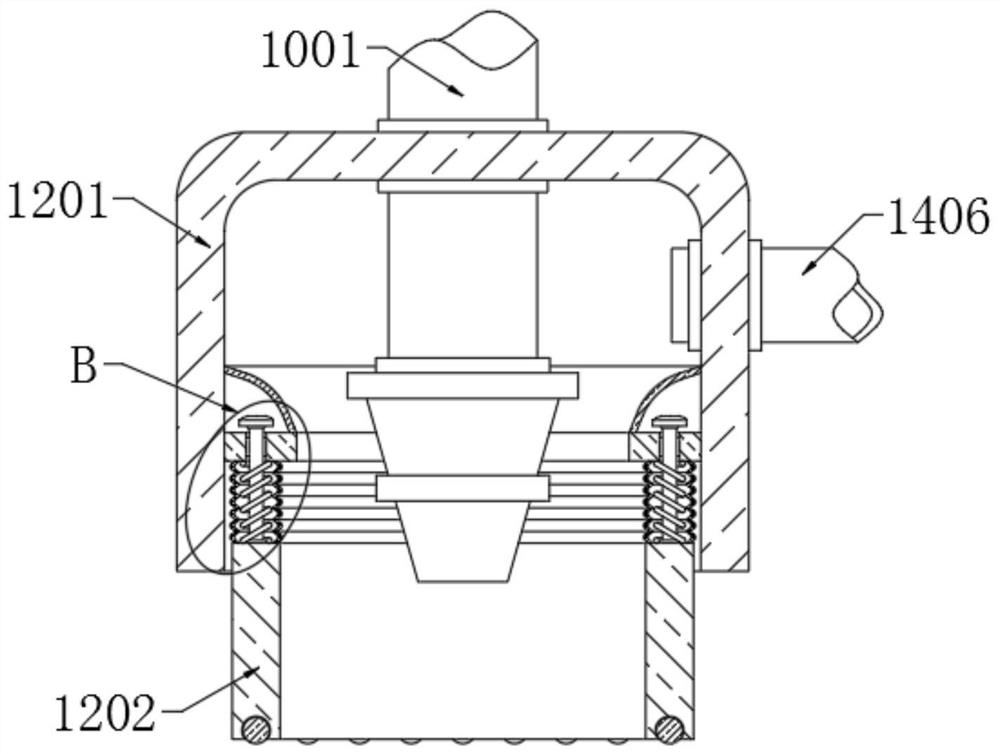

[0030] refer to Figure 1-6 In this embodiment, a metal surface highlight drilling and cutting equipment is proposed, including a base 1, two vertical plates 2 are fixedly installed on the top of the base 1, and the same horizontal plate 3 is fixedly installed on the top of the two vertical plates 2, and the two The same first screw rod 4 is rotatably installed on two risers 2, and a first motor 5 is fixedly installed on one side of one riser 2, and one end of the first screw rod 4 close to the first motor 5 passes through the corresponding riser 2 and is connected with the first riser 2. The output shafts of the first motor 5 are fixedly connected together, the first screw rod 4 is threaded with a first rectangular column 6, the first rectangular column 6 is fixedly mounted with a mounting frame 7, and the mounting frame 7 is rotatably mounted with a second screw rod 8. The second screw rod 8 is provided with a fixed plate 9 on the threaded sleeve. The second motor 10 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com