A long-distance hinge seat positioning welding tool and its positioning welding method

A positioning welding tool and positioning welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of hinge arm deformation, flipping stuck, shaft hole processing difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the function and working principle of each part, etc. will be further described. Details of:

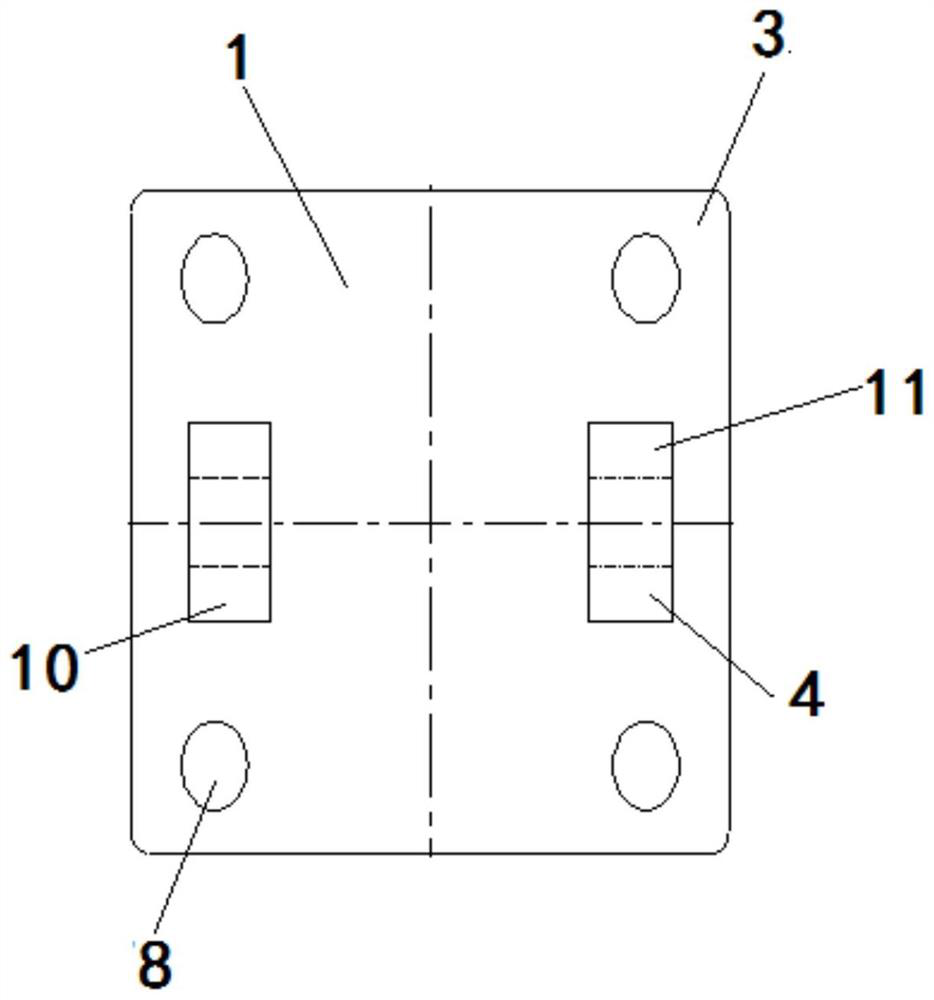

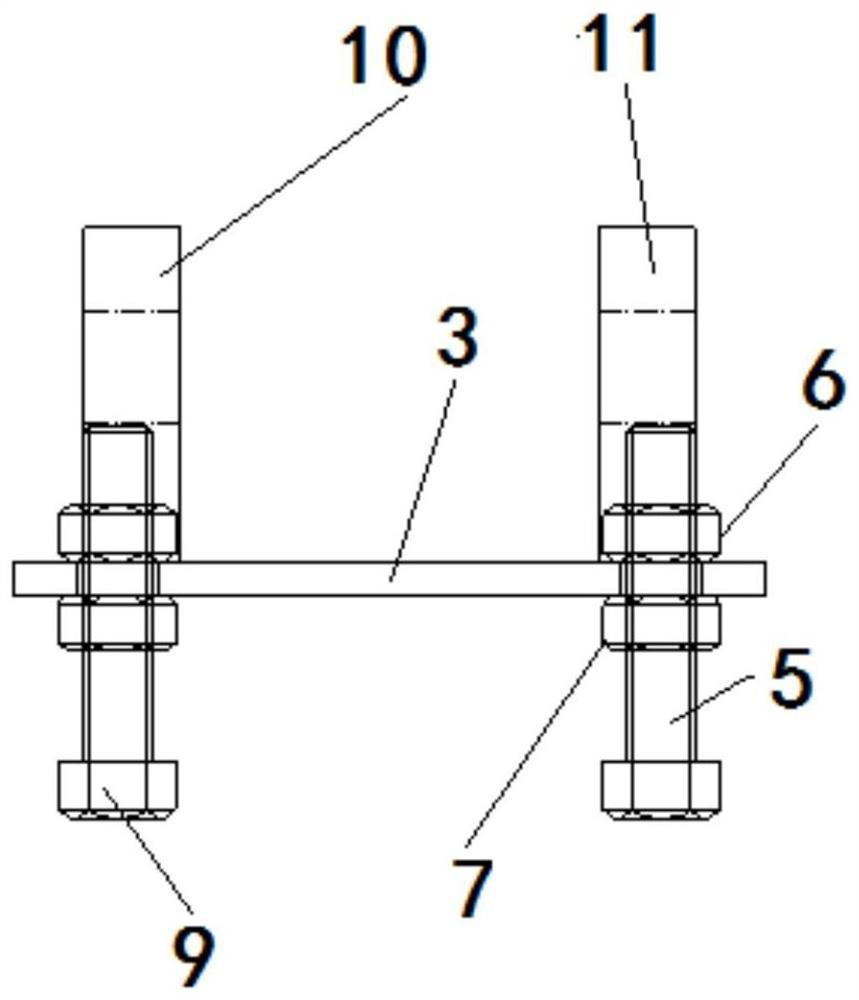

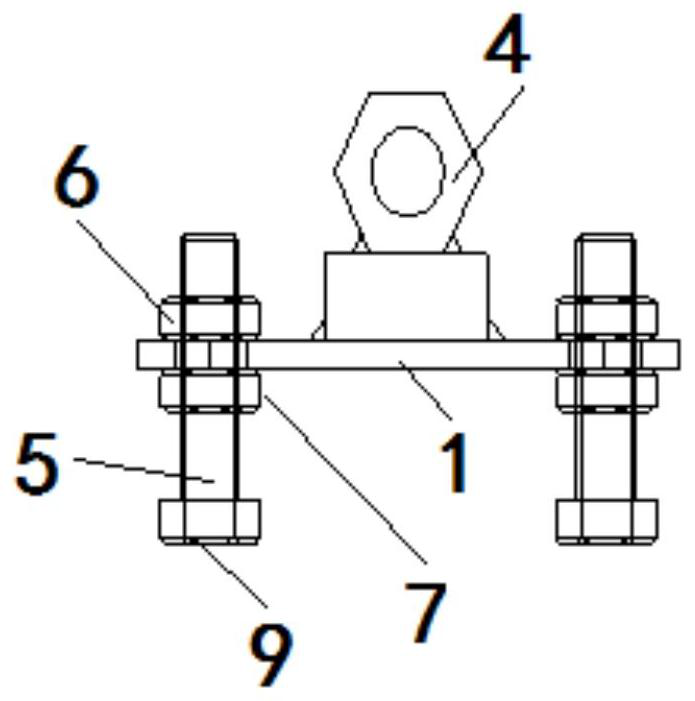

[0032] as attached figure 1 -Attached Image 6As shown, the present invention is a long-spacing hinge seat positioning welding tool, including a plurality of positioning components 1, a correction wire 2, and each positioning component 1 respectively includes a base 3, an ear plate 4, an adjustment bolt 5, an adjustment nut I6, an adjustment Nut II7, the lug plate 4 is welded on one side of the base 3, a plurality of adjustment holes 8 are arranged on the base 3, each adjustment hole 8 passes through an adjustment bolt 5, and the bolt end 9 of the adjustment bolt 5 is located below. The nut I6 is scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com