Umbilical Integrated Coiled Tubing Connector Assembly

A connector assembly and integrated technology, applied in the direction of multi-core cable end parts, electrical components, etc., can solve the problems of fracture, easy corrosion, lack of protection, etc., and achieve the effect of convenient connection, safe use, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

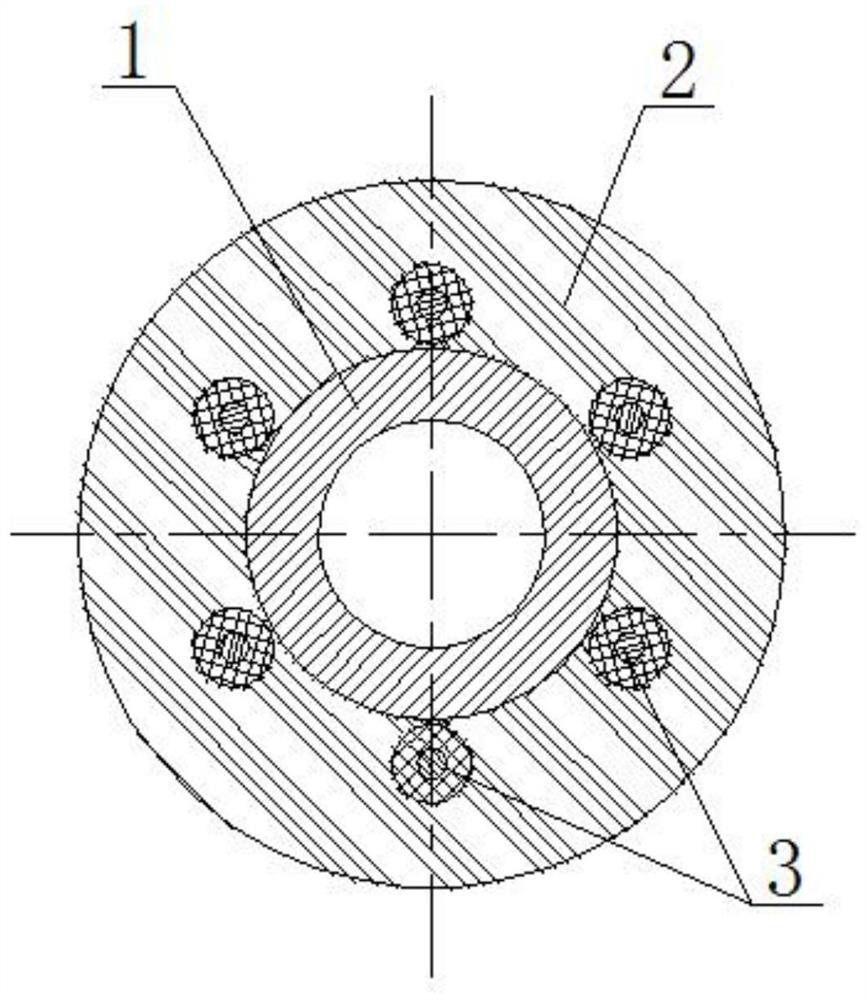

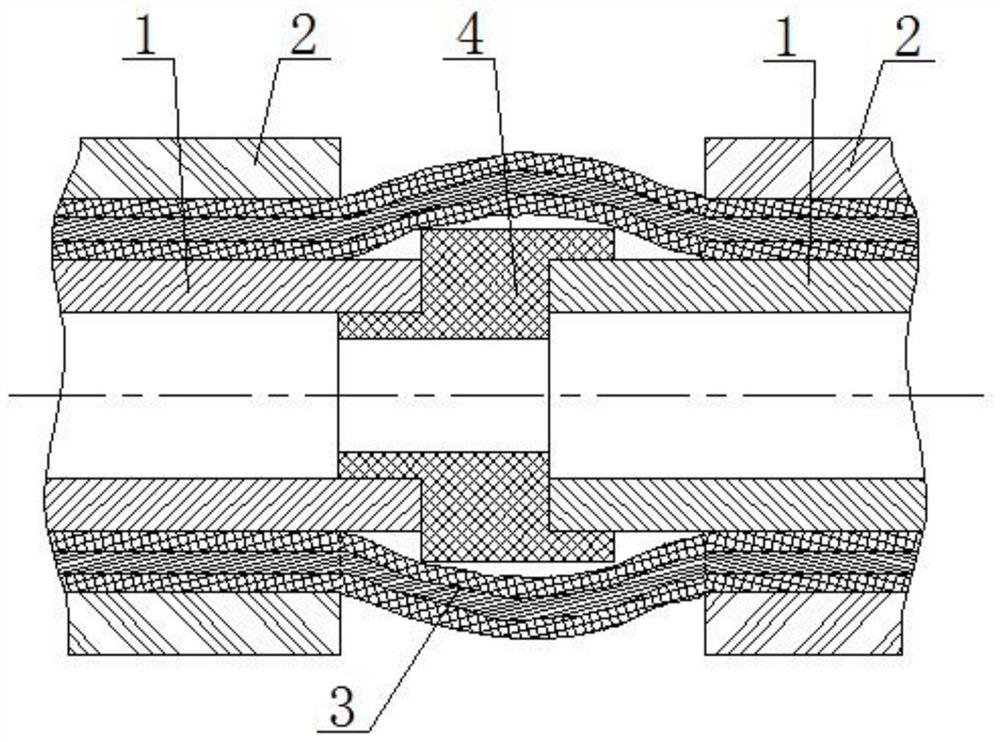

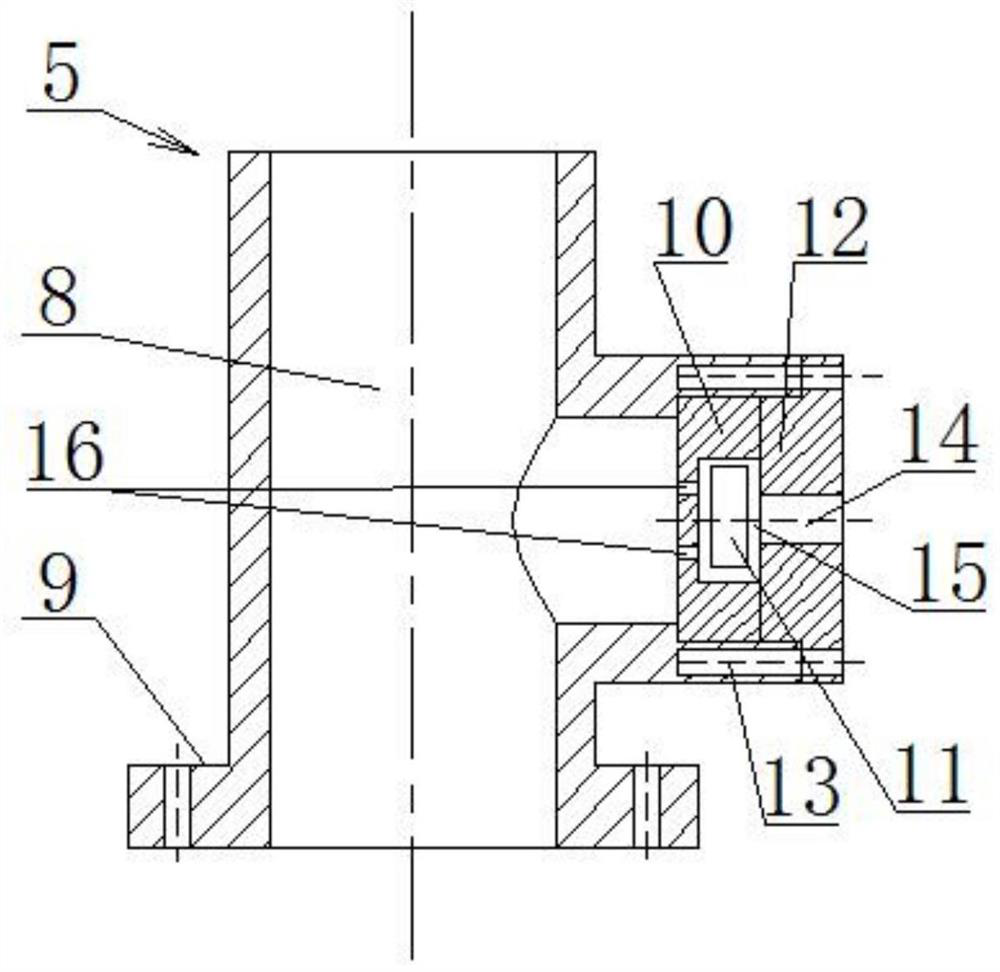

[0026] The umbilical continuous integral pipe connector assembly comprising a wellhead connector 5, the tube connection pipe 6 and the bottom connector 7 (see attached instructions image 3 , 5 And 7).

[0027] 5 comprises a three wellhead connector sleeve 8, adapter flanges 9, intermediate 10, terminal 11 and the valve flap 12 (see the description attached image 3 );

[0028] The lower end of the three-way sleeve 8 with a port adapter flange 9; three-way port side end of the sleeve 8 is pressed by the valve flap 12 with the member 10 (see the description attached image 3 );

[0029] Central flap valve 12 is provided with a cable inlet hole 14 (see the description attached image 3 ); Disk-like intermediate structure 10; intermediate central relief 10 is provided with a counter bore 15; a plurality of relief holes sink connector 15 provided on the side through-hole 16; terminal 11 is attached to relief the counterbore 15 (see instructions attached image 3 with 4 . Terminal 11 is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com