Annular cutting type rectangular pipe jacking machine cutting cutter head

A pipe jacking machine and ring cutting technology, which is used in mining equipment, tunnels, earthwork drilling, etc., can solve the problems of complex cutting structure of square section, and achieve the effect of good excavation effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those of ordinary skill in the art to which the invention pertains can easily implement these embodiments, but the present invention can also be implemented in various forms, Therefore, the present invention is not limited to the embodiments described hereinafter, and in addition, in order to describe the present invention more clearly, components not connected with the invention will be omitted from the drawings.

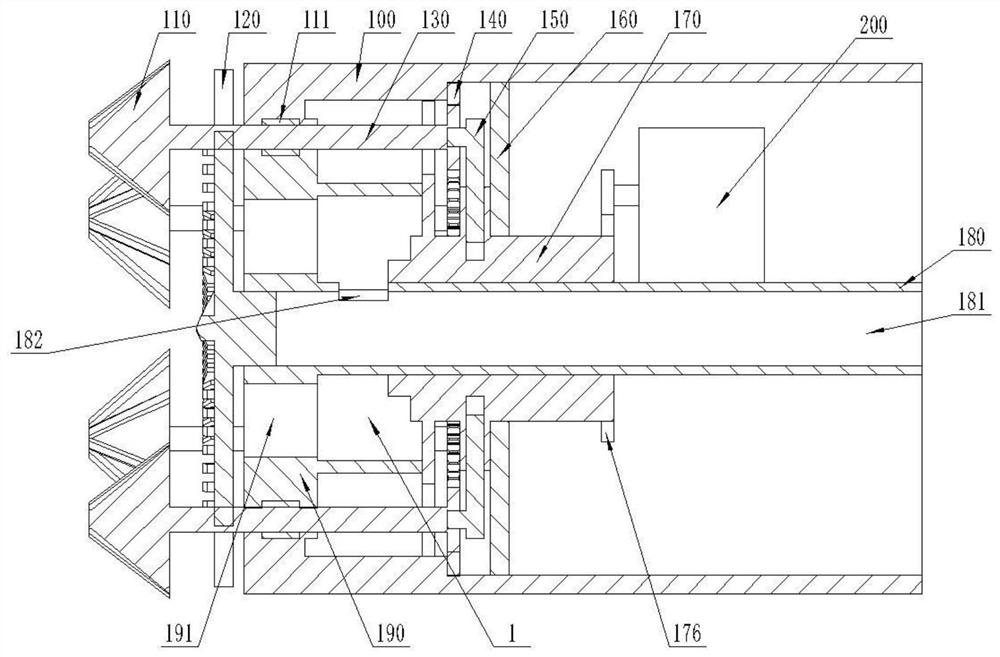

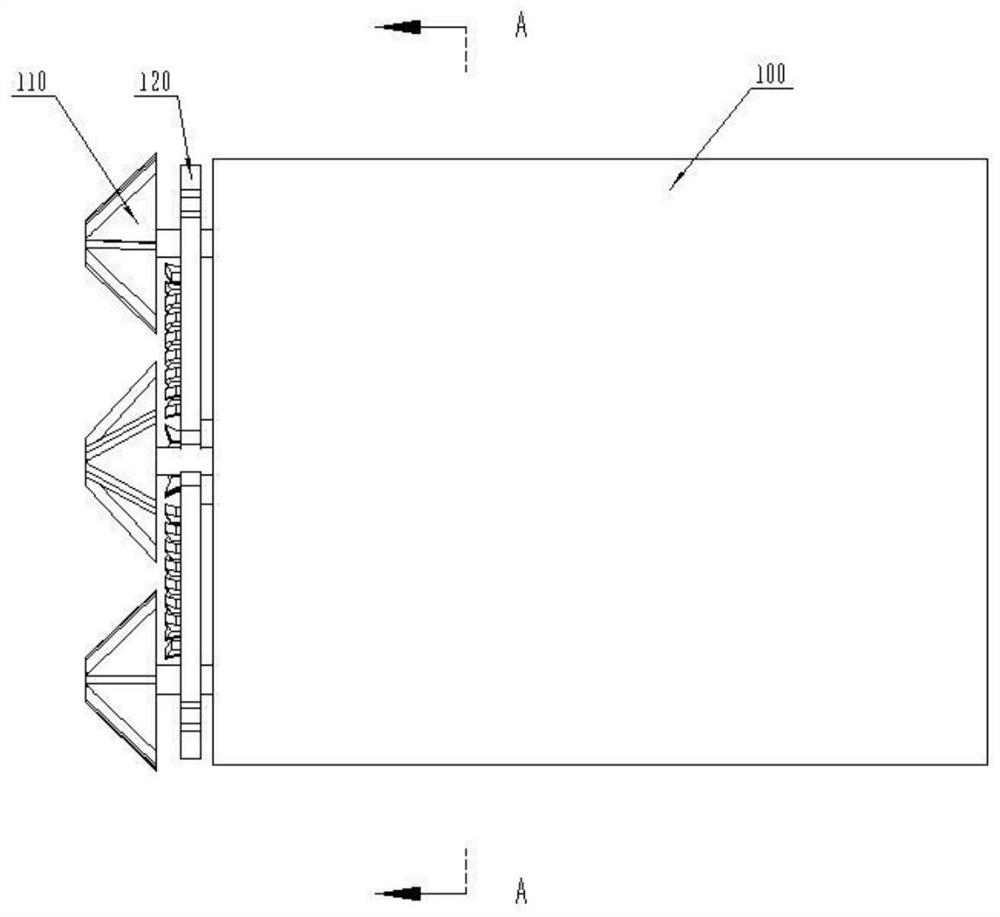

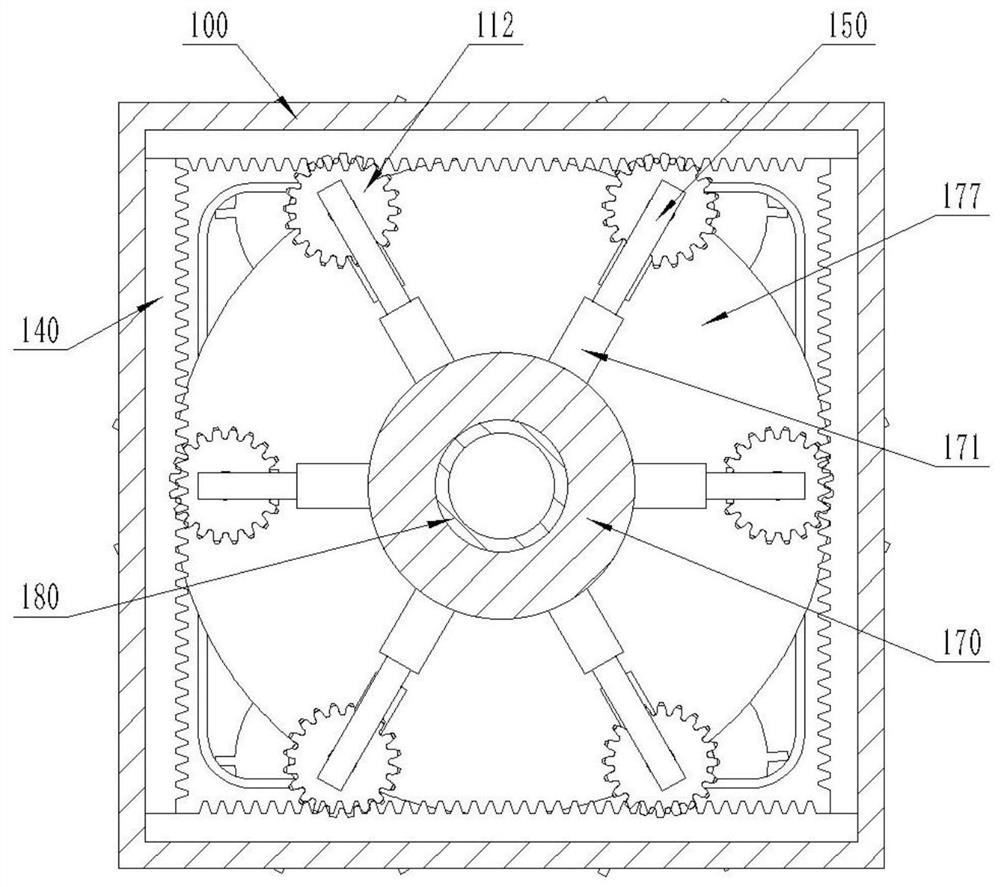

[0024] Such as Figure 1-8 As shown, a cutting cutter head of a ring-cut rectangular pipe jacking machine includes: a protective body 100, a cutting head 110, a main cutting disc 120, a rotating rod 130, a rack 140, a telescopic rod 150, a partition 160, and a rotating body 170 , delivery pipe 180, support body 190, driving motor 200;

[0025] Such as figure 1 , 3 , 4, the circular cutting rectangular cutting shield machine is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com