Formwork construction system and mounting method thereof

A formwork and plate-like technology, applied in the field of formwork construction system and its installation, can solve the problems of high construction cost, heavy workload of pre-embedded steel bars, difficult fixation and operation, etc., to solve the problem of concrete vibration compaction and concrete circulation , Reduce labor intensity and construction cost, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] After long-term research, the applicant found that the existing concrete wall and formwork system has the following disadvantages: 1. The pre-embedding of steel bars is heavy, the construction space is narrow, and it is not easy to fix and operate, and the labor cost is high and the efficiency is low; 2. Construction At the same time, wooden formwork or other formwork needs to be additionally equipped with a complex support system on the outside to prevent the formwork from toppling over, which makes the construction cost high; The demand for installing decorative panels on the wall, especially for high-end office buildings and high-end buildings, is ubiquitous. For this reason, prior art all is to re-drill on the concrete body of wall and install anchor point and fixed support, and finish panel is installed on support at last. This method has deficiencies in construction efficiency, production cost, and safety and stability.

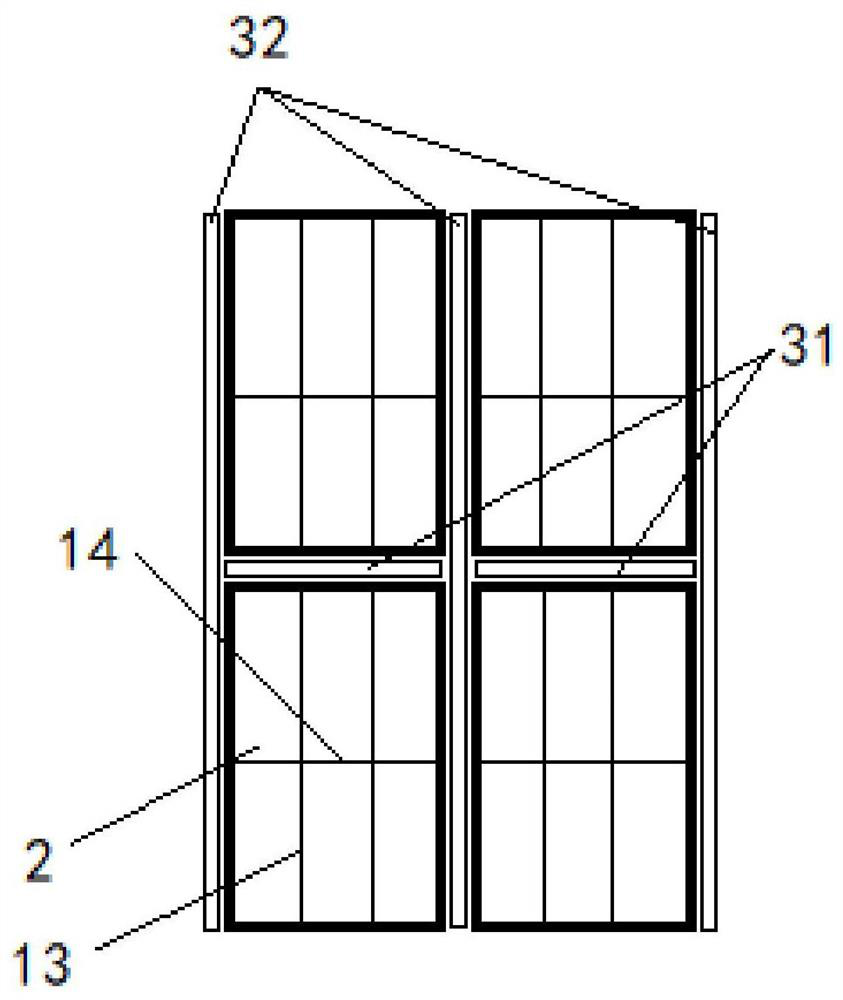

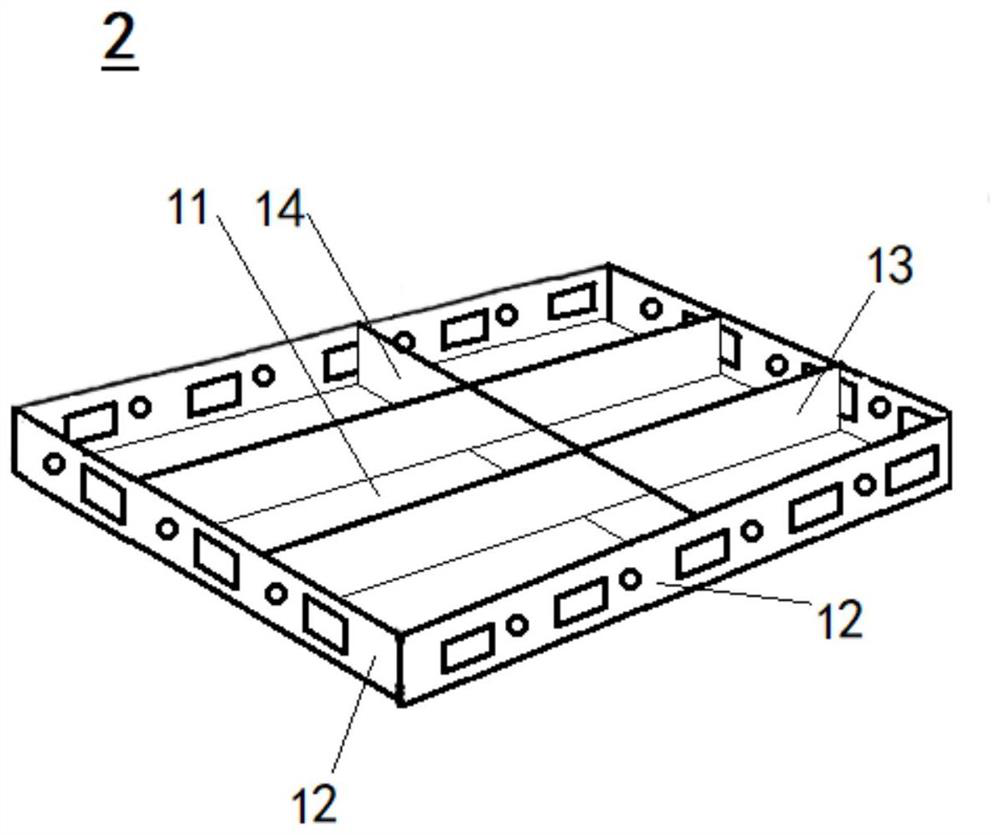

[0042] For this, see figure 1 , a formwo...

Embodiment approach

[0053] According to another preferred embodiment of the present invention, there is also an installation method according to the aforementioned formwork construction system, which is characterized in that it includes the following steps:

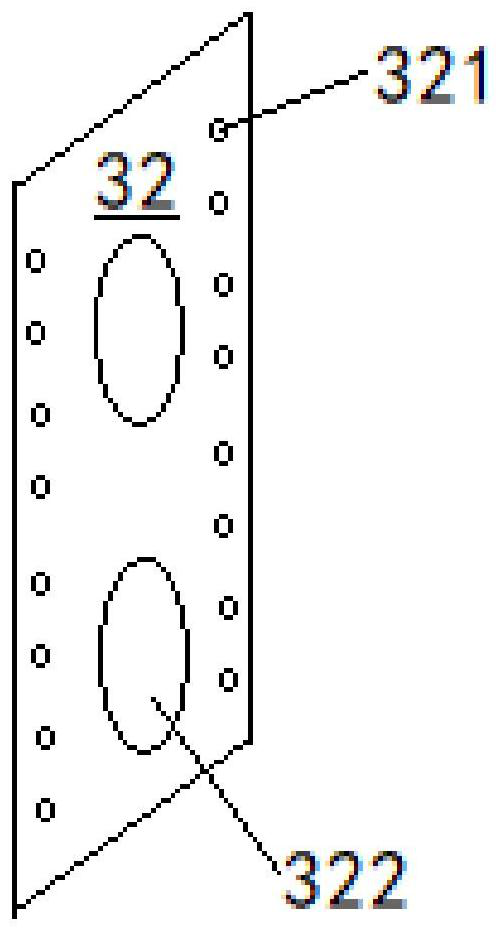

[0054] The first stainless steel plate frame 32 is arranged along the first direction, and the two stainless steel templates 2 of the first template unit and the second stainless steel template 2 are respectively arranged in the second direction in an orthogonal manner on both sides of the first stainless steel plate frame 32. The two stainless steel templates 2 of the two template units are connected to the adjacent side plates of the two stainless steel templates 2 and the second adjacent side plates through the connectors arranged in the fifth through hole and the first through hole 321. A stainless steel plate skeleton 32;

[0055] Arrange the second stainless steel plate frame 31 along the second direction, and arrange the two stainless...

Embodiment 2

[0082] On the basis of Embodiment 1, the formwork construction system may further include a temperature monitoring system.

[0083] According to yet another preferred embodiment of the present invention, in the prior art, cracks or fractures often occur inside construction buildings in harsh environments, and the temperature inside the buildings is difficult to detect. In order to prevent cracks or breaks due to excessive temperature difference between inside and outside during the pouring process, and to facilitate internal temperature monitoring, a temperature monitoring system is also provided.

[0084] see Figure 5 , through holes are set on the two stainless steel panels 11 of the stainless steel formwork 2 that are arranged oppositely, the hollow threaded steel bar 3 that runs through the two stainless steel panels 11 is set in the through hole, and the threaded connection is set in the central hole of the hollow threaded steel bar 3 5, the threaded connection 5 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com