Pocket patching machine workstation

A bag patching machine, workstation technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of manual duty and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

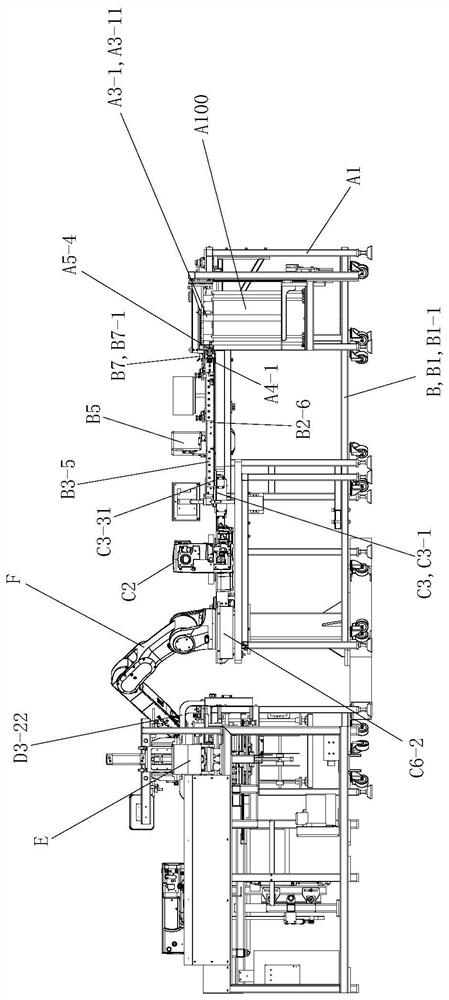

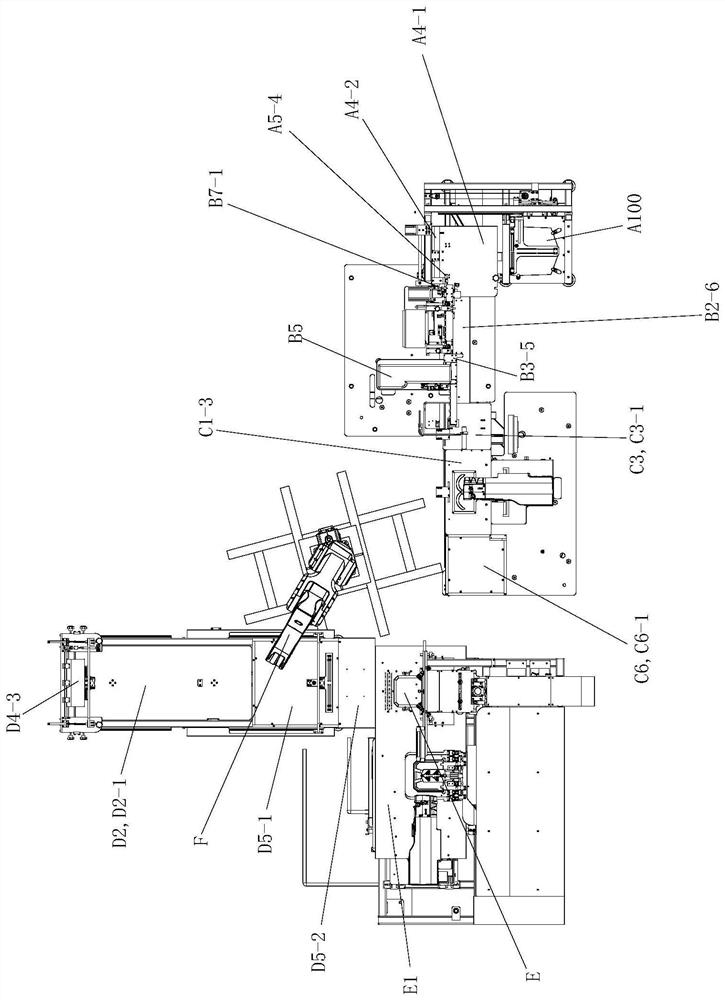

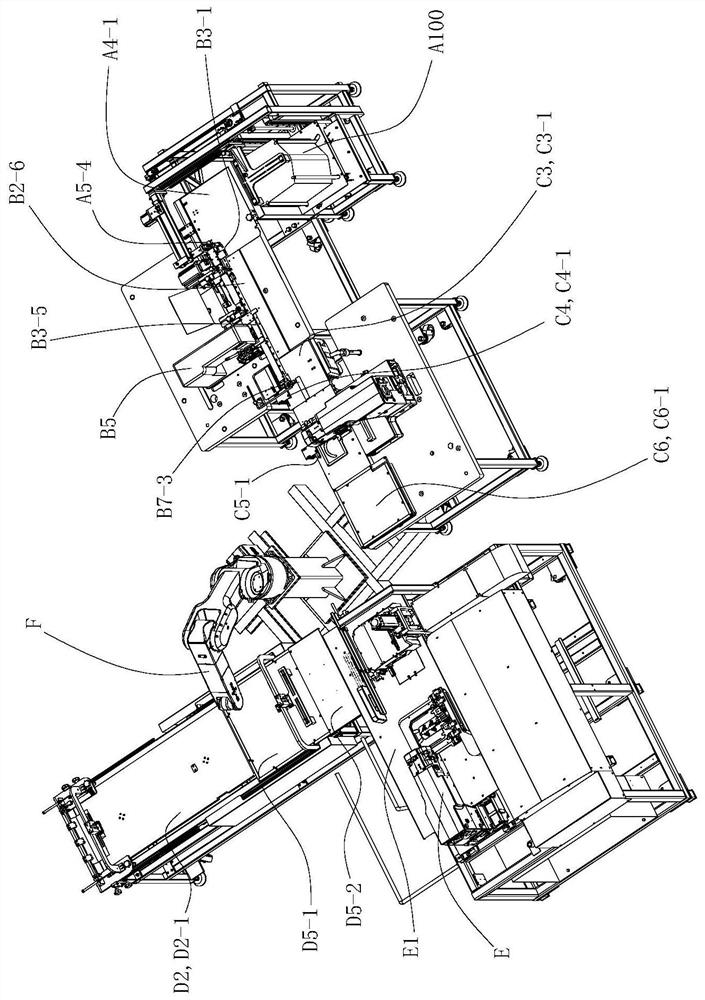

[0179] See Figure 1 to Figure 55 , Pocket patching machine workstation of the present invention includes pocket cloth feeding device A, crimping machine B, pocket flower machine C, body feeding device D, bagging machine E and industrial robot F. The bag sticking machine E adopts the fully automatic cold folding bagging machine recorded in the patent literature with the patent application number 201811542712.0. The industrial robot F is a prior art, and this embodiment is an industrial robot for sewing purchased by Luoshi (Beijing) Technology Co., Ltd. The bag sticking machine E is arranged on the left side of the bag flower machine C.

[0180] See Figure 1 to Figure 8 and Figure 22 to Figure 32, The pocket cloth feeding device A includes the pocket cloth discharging frame A1, the pocket cloth lifting mechanism A2, the pocket cloth splitting mechanism A3, the pocket cloth material receiving mechanism A4 and the pocket cloth loading mechanism A5.

[0181] See Figure 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com