Workpiece distribution mechanism for intelligent production line

A technology for workpieces and production lines, applied in the field of workpiece distribution mechanisms of smart production lines, can solve problems such as reduced production efficiency, save system energy consumption, and avoid long-term no-load operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

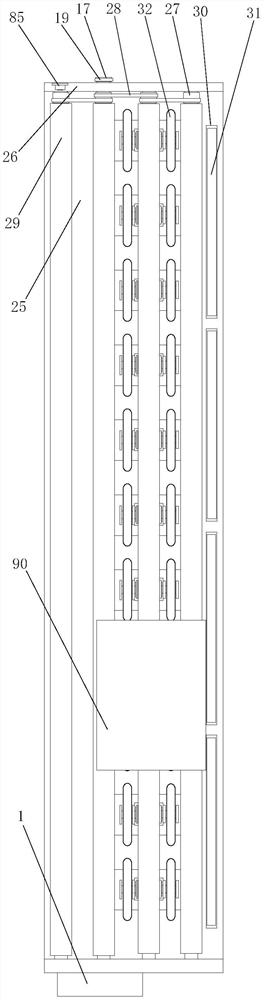

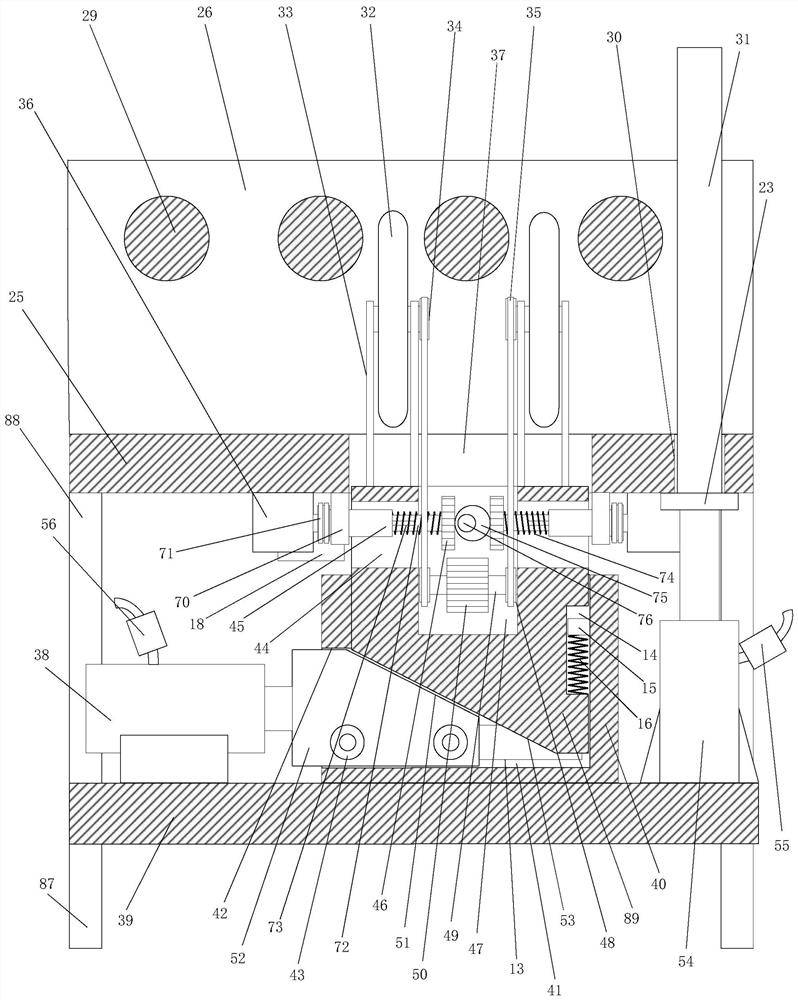

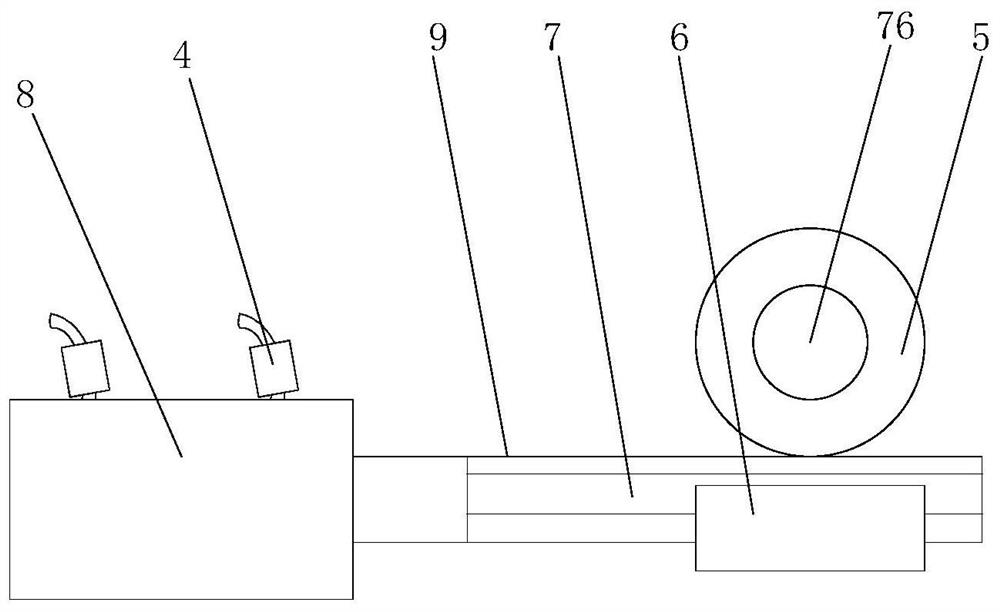

[0021] Such as Figure 1-4 As shown, the workpiece distribution mechanism for smart production lines disclosed by the present invention includes: a distribution control box 1, a distribution conveying roller bed, a lateral transfer mechanism, and a blocking and limiting mechanism;

[0022] The traversing transfer mechanism is installed on the unloading side of the distribution conveying roller bed, and is used for laterally conveying the workpiece 90 on the unloading side; the blocking limit mechanism is installed on the unloading side of the distribution conveying roller bed, and is located at the The rear side is used to block and control the workpiece 90 on the unloading side of the distribution conveying roller bed; a position sensor 85 on the feeding side is arranged on the feeding side of the distribution conveying roller bed;

[0023] The distribution control box 1 is installed on the distribution conveying roller bed, and is provided with a controller, a wireless commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com