Automatic clamping and adsorbing mechanism

A technology of clamping mechanism and adsorption mechanism, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as product quality decline and deviation in various operations, and achieve the effect of increasing the fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

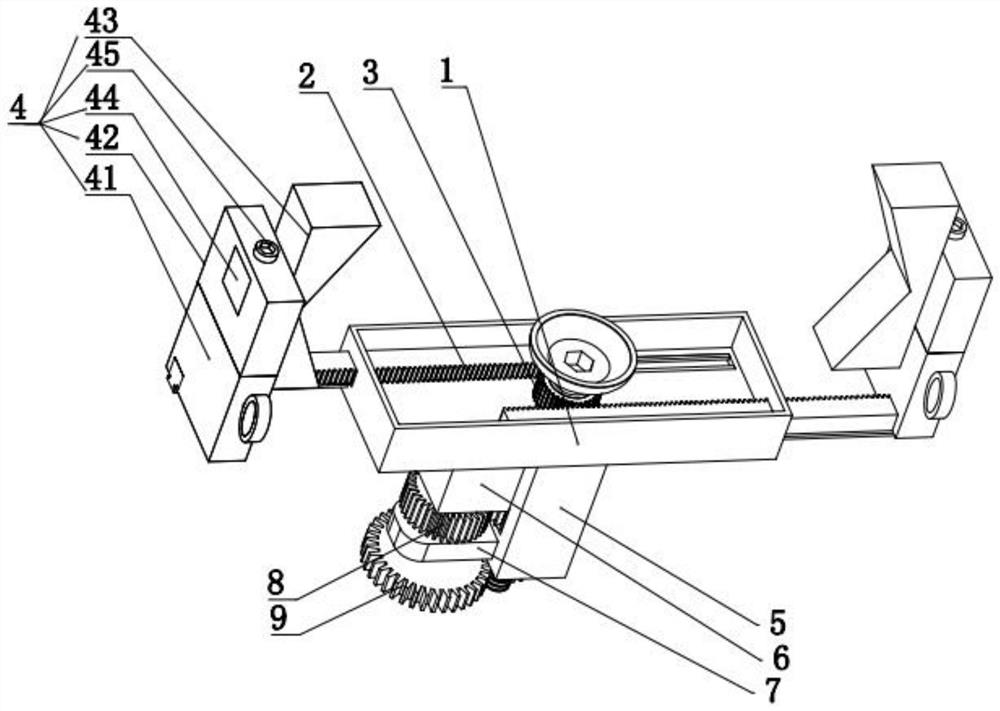

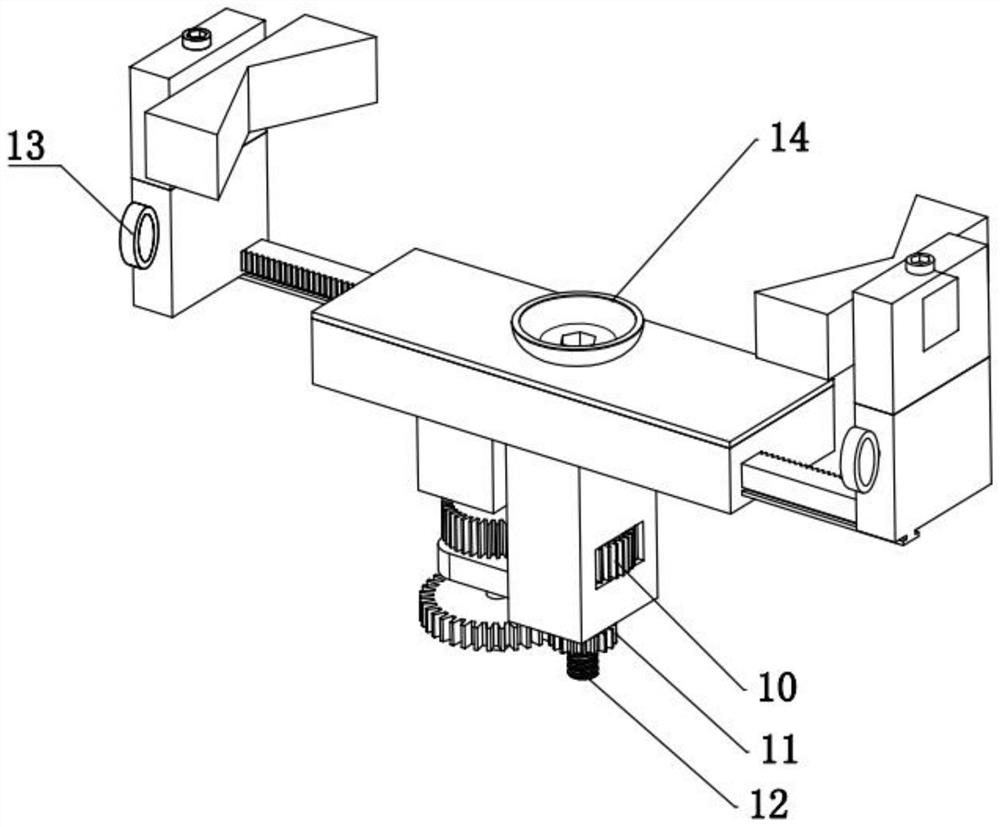

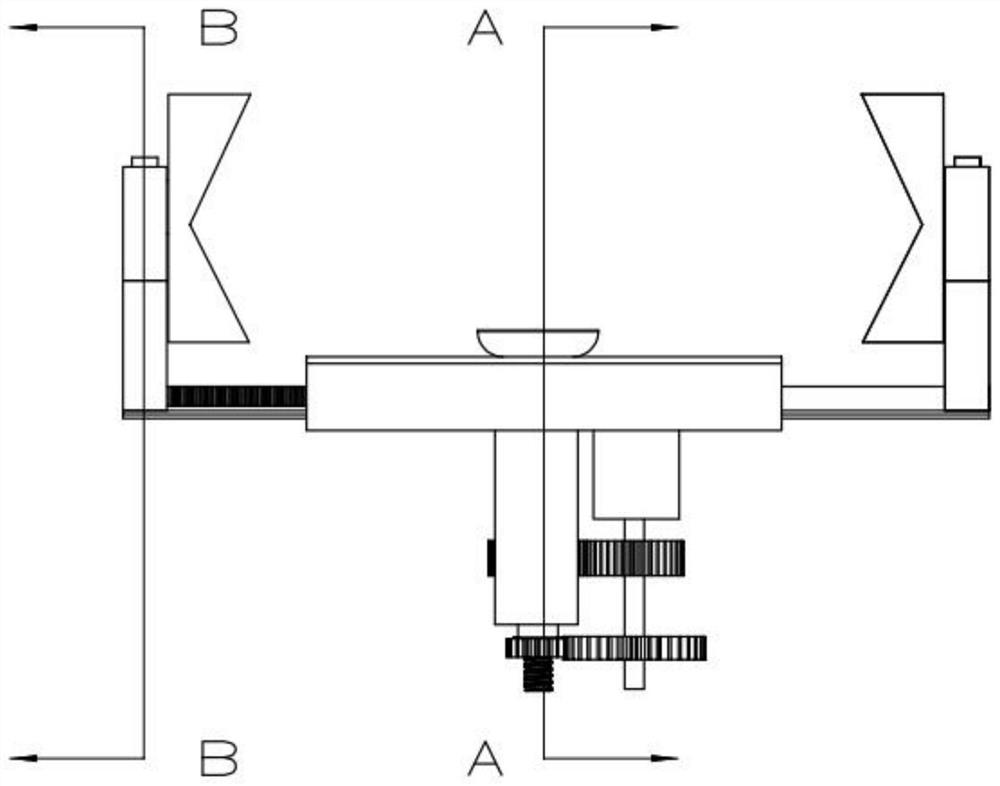

[0030] A kind of automatic suction mechanism, with reference to figure 1 As shown, it includes a hollow clamping base 1 and a clamping mechanism arranged on the clamping base 1. The upper end of the clamping base 1 is detachably provided with an end cover through screws, and the clamping mechanism includes clamps located at both ends of the clamping base 1. The holding block 4, the driving gear 3 that is rotated at the bottom of the inner cavity of the clamping base 1, and the moving rack 2 that is slidably embedded on both sides of the driving gear 3 at the bottom of the inner cavity of the clamping base 1 and engages with the driving gear 3, The opposite ends of the moving rack 2 are respectively fixed to the clamping blocks 4 located at both ends of the clamping base 1 . With the forward and reverse rotation of the driving gear 3, the clamping block 4 can be relatively close to or far away from. In the above arrangement, a slide block that gradually increases from top to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com