Efficient screening equipment for static contacts of electric appliance accessories

A technology for electrical accessories and screening equipment, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of low work efficiency and large labor output, and achieve the goal of improving work efficiency, saving labor, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

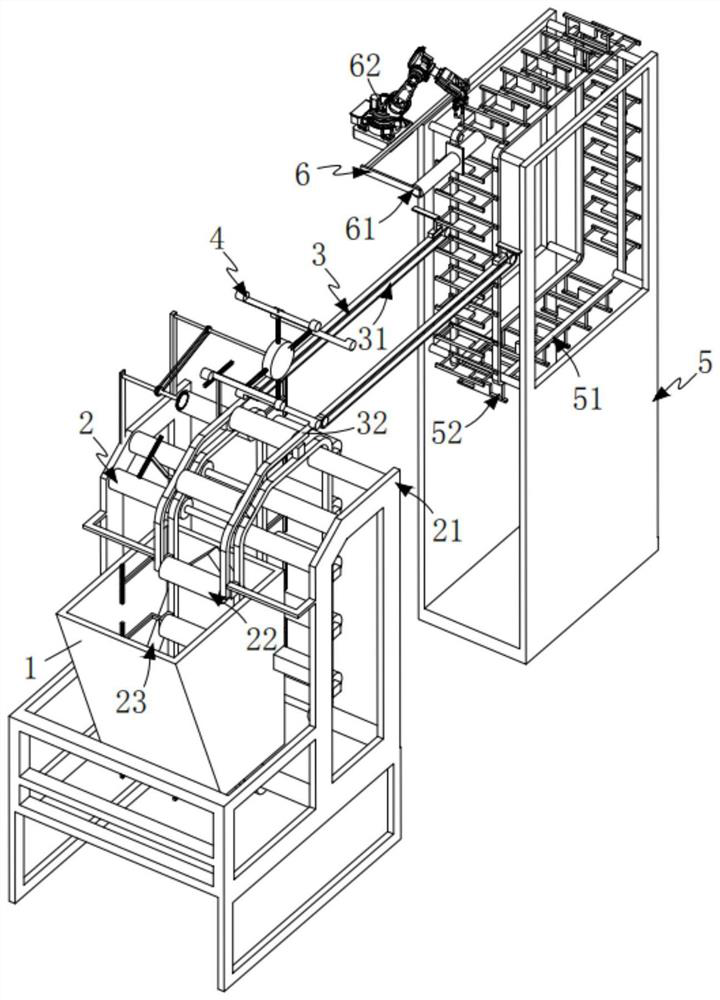

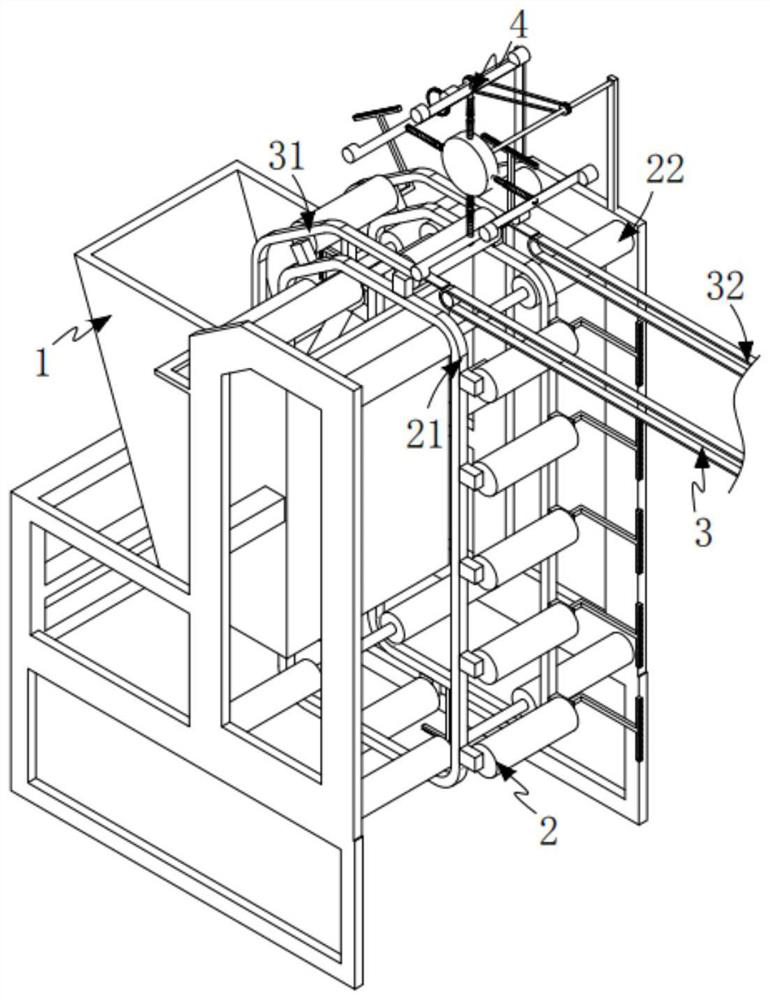

[0054] like figure 1 and figure 2 As shown, a static contact high-efficiency screening equipment for electrical accessories, including:

[0055] A storage bin 1, the storage bin 1 is set in an inverted conical structure;

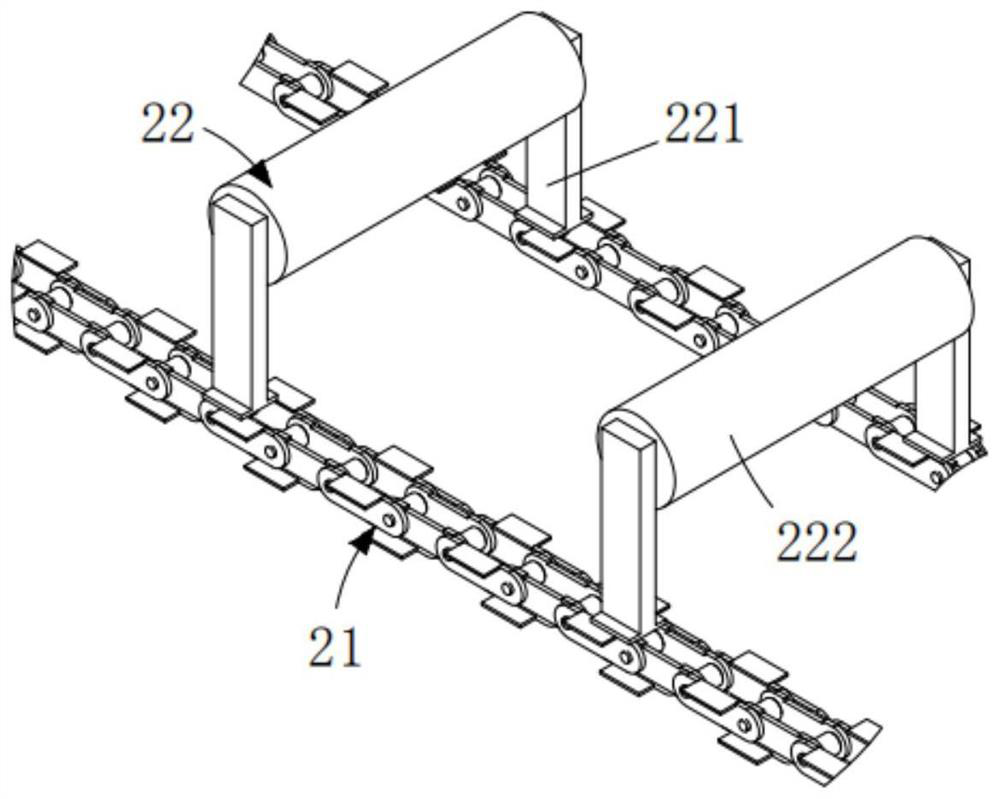

[0056] The hooking mechanism 2, the hooking mechanism 2 is arranged in several groups at equal intervals along the length direction of the storage bin 1. The transmission assembly 21, the hook assembly 22 installed on the first transmission assembly 21 and arranged at equal intervals along the transmission direction of the first transmission assembly 21, and the adjustment assembly arranged on one side of the hook assembly 22 twenty three;

[0057] The sorting mechanism 3, the sorting mechanism 3 is provided with several groups and is provided with several groups corresponding to the first transmission assembly 21 one by one, which includes the first guide assembly 31 and is arranged on the output end of the first guide assembly 31 and is connected with ...

Embodiment 2

[0090] like Figure 9 and Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0091] further, such as Figure 9 and Figure 10 As shown, the toggle mechanism 4 includes a transmission assembly 41 and a push assembly 42;

[0092] The transmission assembly 41 includes a transmission rack 411 fixedly connected to the connecting rod 221, a transmission gear 412 meshed with the transmission rack 411 and rotatably provided on the frame, coaxial with the transmission gear 412 and The pulley a413 of synchronous transmission and the pulley b414 of synchronous transmission with said pulley a413;

[0093] The pushing assembly 42 includes a drive shaft 421 coaxially driven with the pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com