A Spraying Robot Based on Visual Recognition and Positioning

A spraying robot and visual recognition technology, applied in manipulators, spray booths, spraying devices, etc., can solve the problems of thick wrists and inability to spray small-hole workpieces, and achieve the effect of accurate probe positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

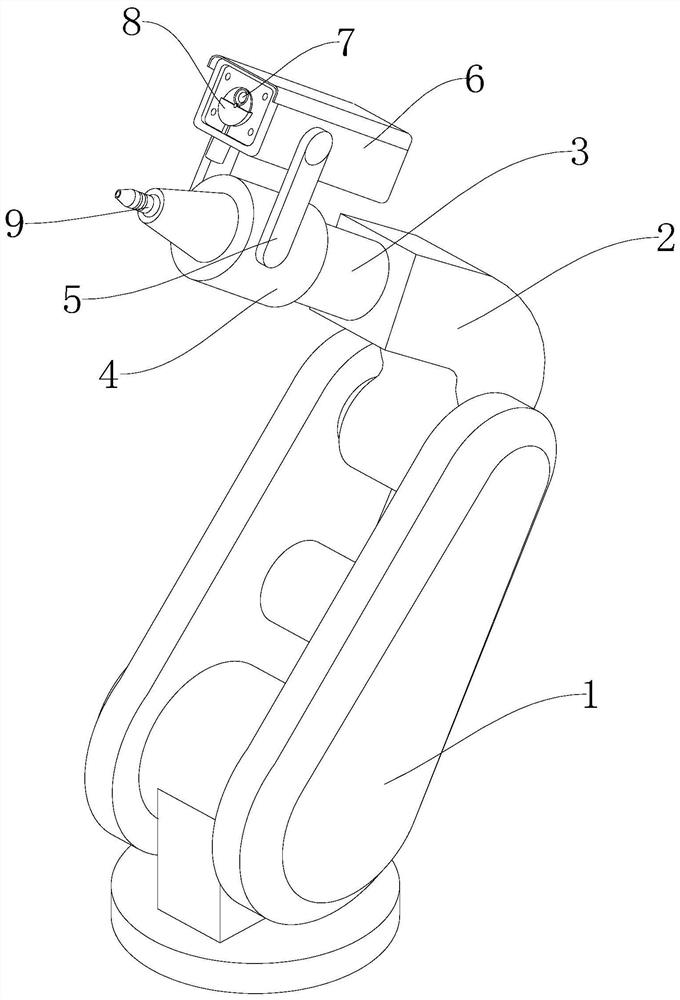

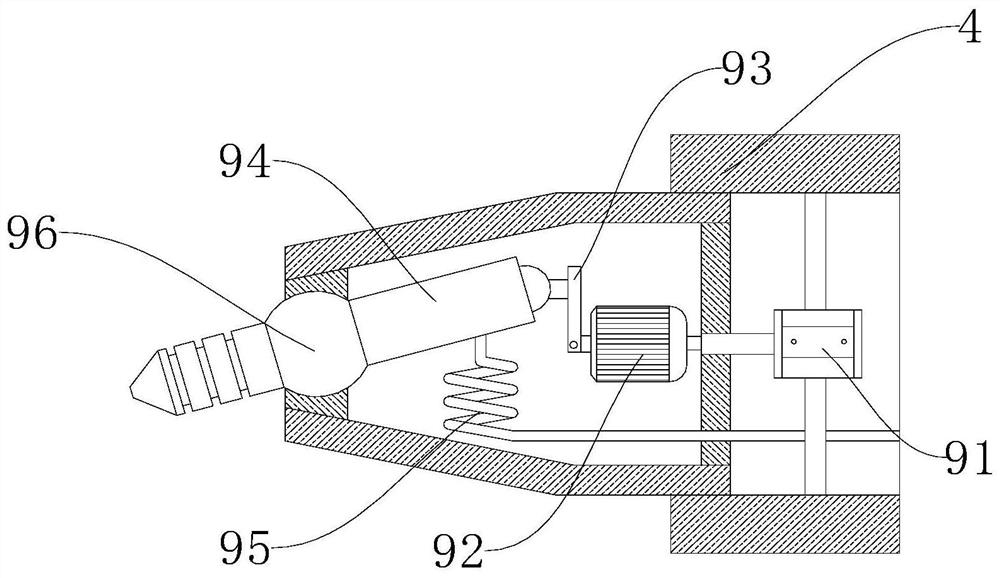

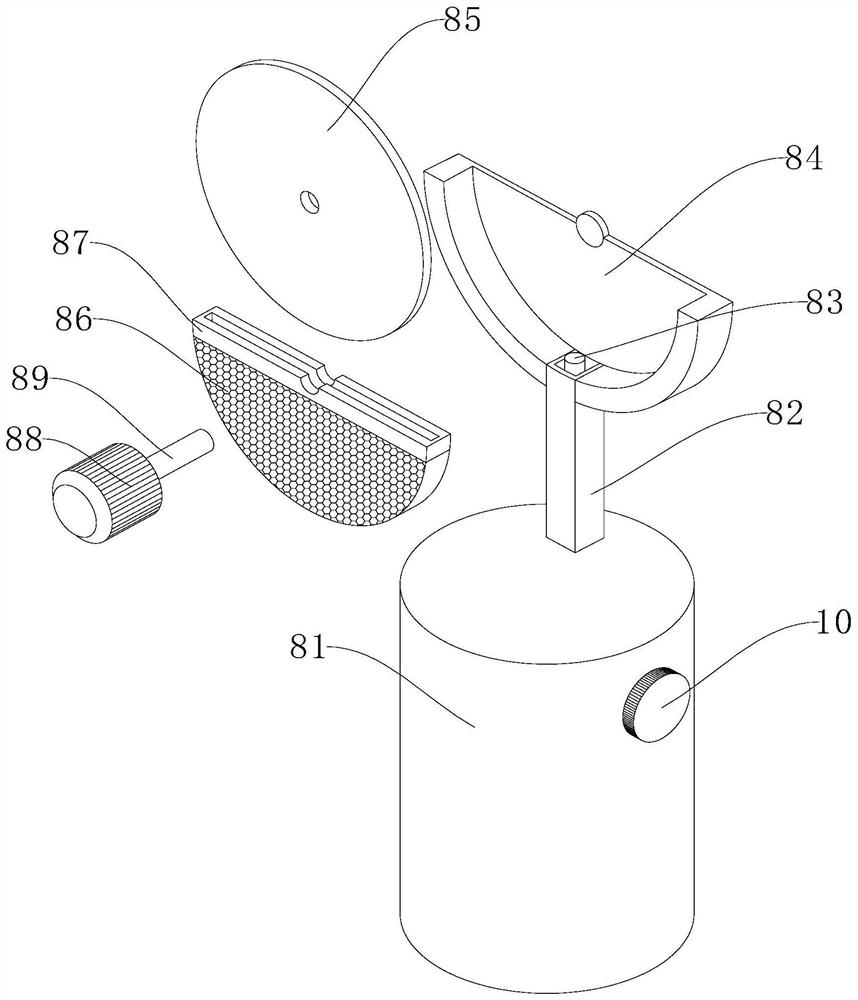

[0024] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a spraying robot based on visual recognition and positioning of the present invention includes a main segment mechanical arm 1, a second segment mechanical arm 2 movably connected to the top of the main segment mechanical arm 1, and a rotating arm that is rotatably connected to the front end of the second segment mechanical arm 2 3 and the three-section mechanical arm 4 movably connected to the front end of the rotating arm 3, the top of the three-section mechanical arm 4 is provided with a monitoring probe 6, the monitoring probe 6 is movably connected with the three-section mechanical arm 4 through the probe support frame 5, and the monitoring probe 6 The front end is interspersed with a camera lens 7, the front end of the camera lens 7 is provided with a lens cleaning structure 8, and the inside of the three-section mechanical arm 4 is provided with an adjustable nozzle structure 9, and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com