A kind of in-phase traction power supply power generation system and control method

A power generation system and traction power supply technology, applied in photovoltaic power generation, electric traction, AC networks with the same frequency from different sources, etc. The effect of promoting green development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

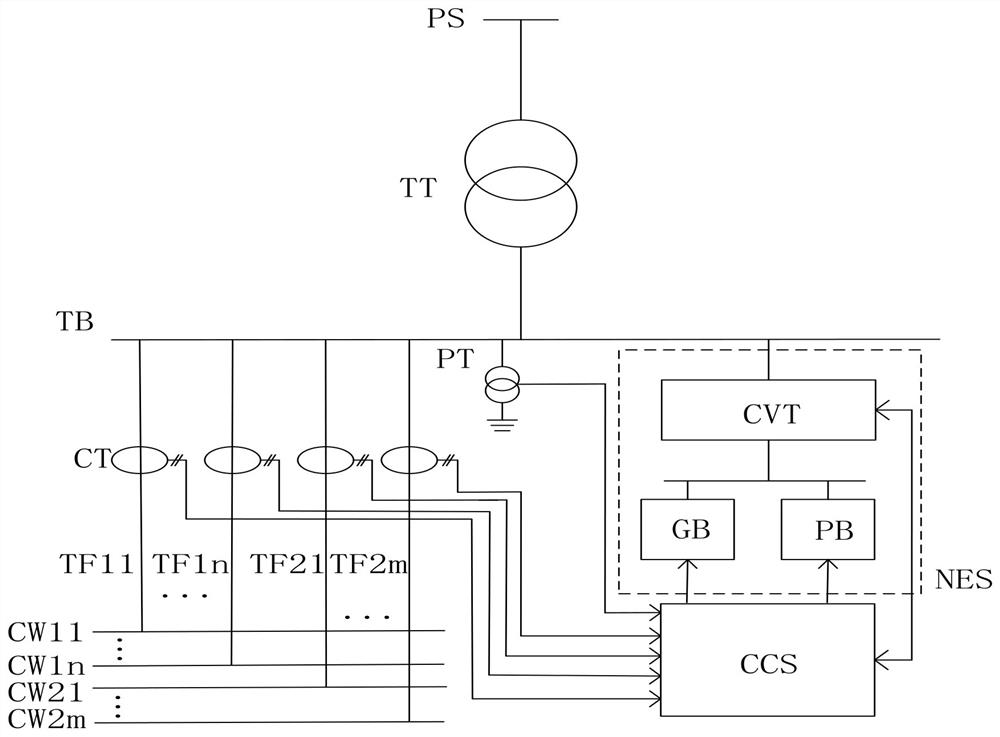

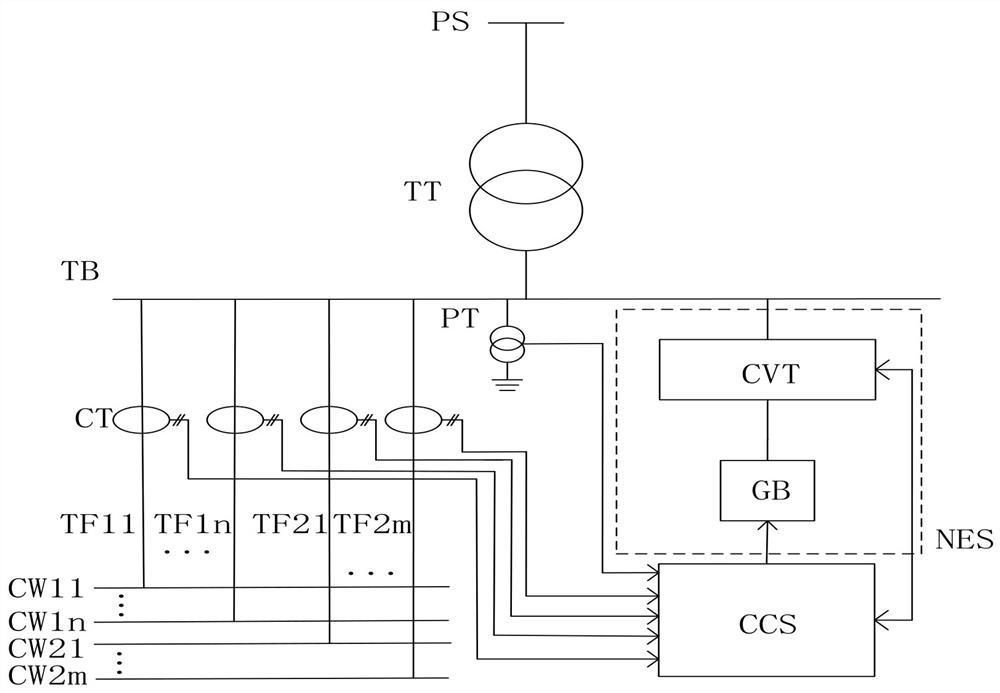

[0033] like figure 1 As shown, this embodiment provides an in-phase traction power supply power generation system, including a traction transformer TT, a traction bus TB and a feeder TF, and the secondary side of the traction transformer TT is connected to the traction bus TB. It is characterized in that: the traction bus TB is provided with There is a voltage transformer PT, and the AC output terminal of the new energy power generation device NES is connected to the traction bus TB. The feeder TF is divided into n upstream feeder lines TF11, TF12, ..., TF1n and m downstream feeder lines TF21, TF22, ..., TF2m , each upstream feeder and each downstream feeder are equipped with a current transformer CT, n≥2, m≥2, wherein: the first ends of the n upstream feeders TF11, TF12, ..., TF1n are connected to the traction bus TB Connection, the end of n uplink feeders TF11, TF12, ..., TF1n is connected to n uplink catenary lines CW11, CW12, ..., CW1n; Connection, m downlink feeder lines...

Embodiment 2

[0043] like Figure 4 As shown, this embodiment provides a control method based on the same-phase traction power supply power generation system provided in Embodiment 1, which is applied to the coordination controller CCS, and the method includes:

[0044] S1: The coordinating controller CCS obtains the voltage information measured by the voltage transformer PT and the current information measured by each current transformer CT; S2: According to the voltage information and current information, n upstream feeder lines TF11 and TF12 are calculated respectively , ..., the active power P11, P12, ..., P1n of TF1n and the active power P21, P22, ..., P2m of m downlink feeders TF21, TF22, ..., TF2m, where the active power flowing to the catenary is the traction power, denoted as Positive, active power flowing to the traction bus is regenerative power, recorded as negative;

[0045] S3: The active power P11, P12, ..., P1n of the n uplink feeder lines TF11, TF12, ..., TF1n are summed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com