Manufacturing method of open-air limestone mine power supply system grounding device

A technology of power supply system and grounding device, which is applied in the direction of circuits, connections, electrical components, etc., and can solve problems such as non-compliance with energy saving and emission reduction, production cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The features and performances of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

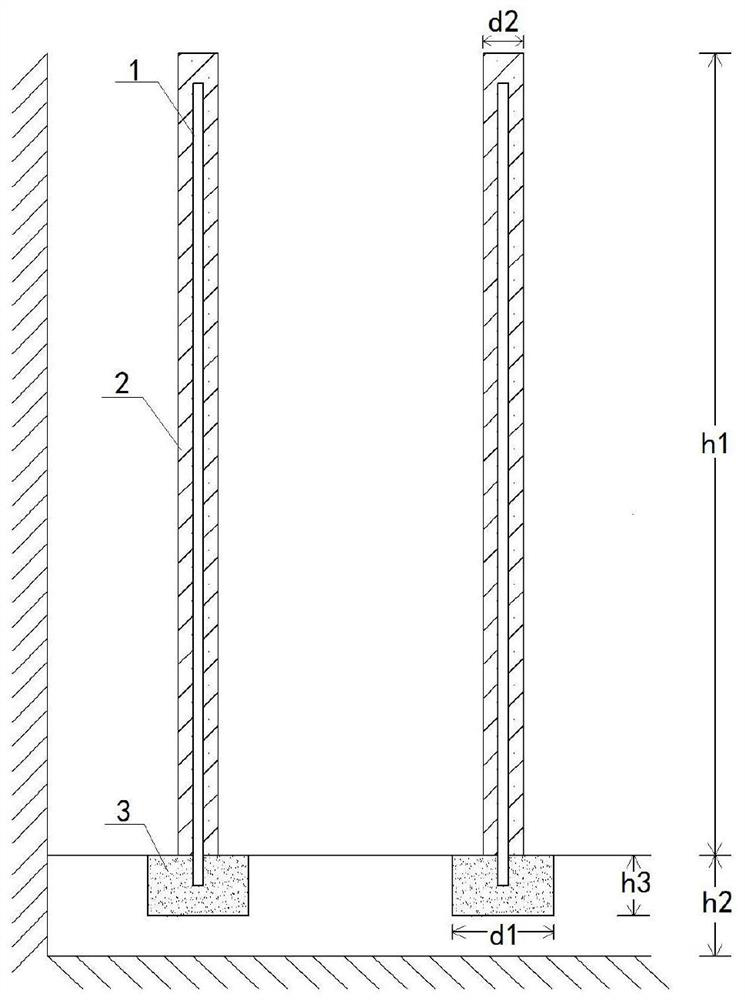

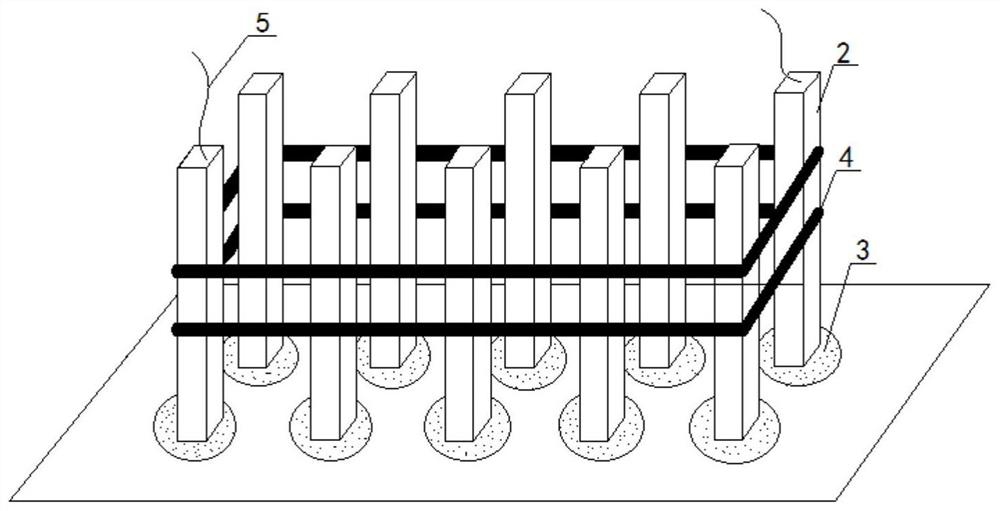

[0027] Such as figure 2 with Figure 4 As shown, here we take a certain actual size as an example to illustrate this method. The excavation depth of the foundation pit is h1+h2=4.5m, the width d6=6m, the length d5=30m, the distance between the ground electrodes 1 in the width direction d4=2m, and the distance in the long direction Spacing d3=3m, radius of cylindrical area r=0.25m, diameter d1=0.5m, depth h3=0.3m, formwork width and length d2 both 0.2m, height h1=0.4m.

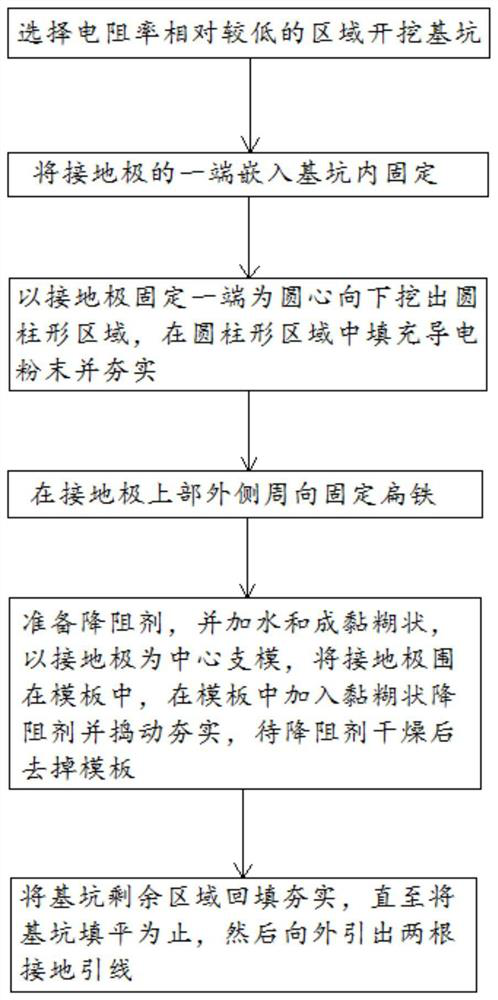

[0028] Such as figure 1 with image 3 As shown, a method for making a grounding device for an open-pit limestone mine power supply system includes the following steps:

[0029] S1. Select an area with relatively low resistivity in the open-pit stope through testing, and excavate a grounded foundation pit in this area. The length of the foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com