Neutron transmission imaging system for prefabricated wall detection and application thereof

An imaging system and prefabricated technology, applied in the direction of material analysis using wave/particle radiation, material analysis using radiation, measuring devices, etc., can solve the problems of insufficient equipment for detecting the connection quality of prefabricated buildings, and achieve good applicability , high work efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

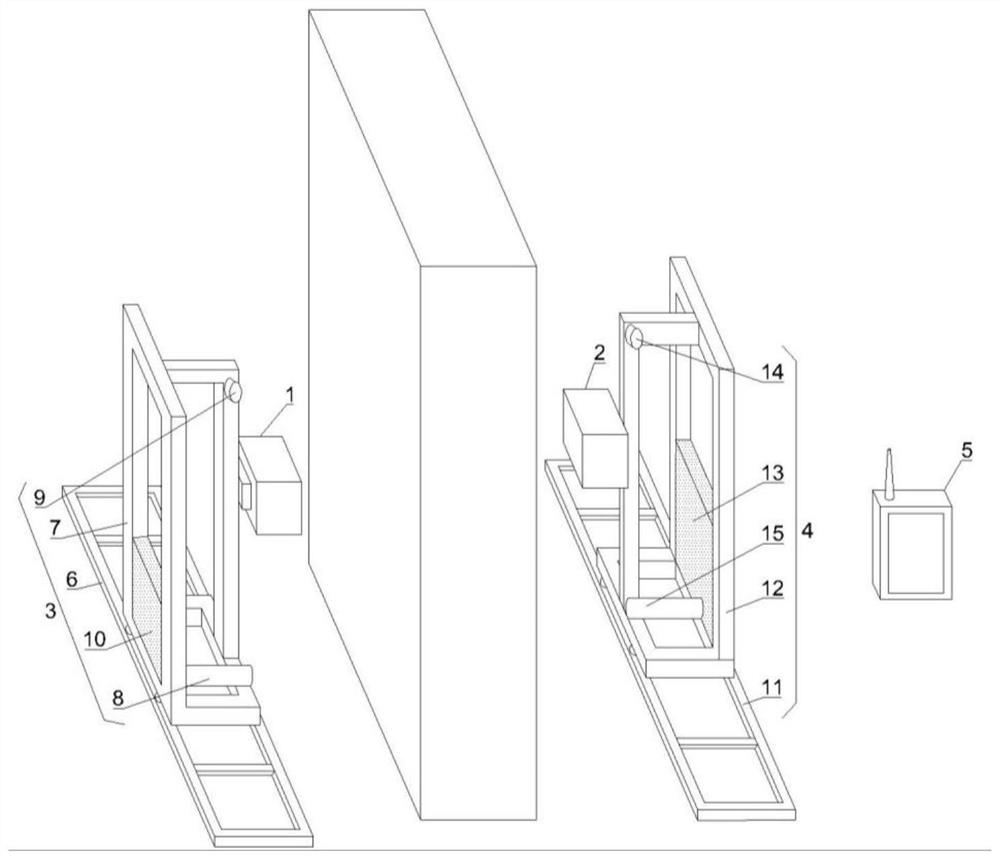

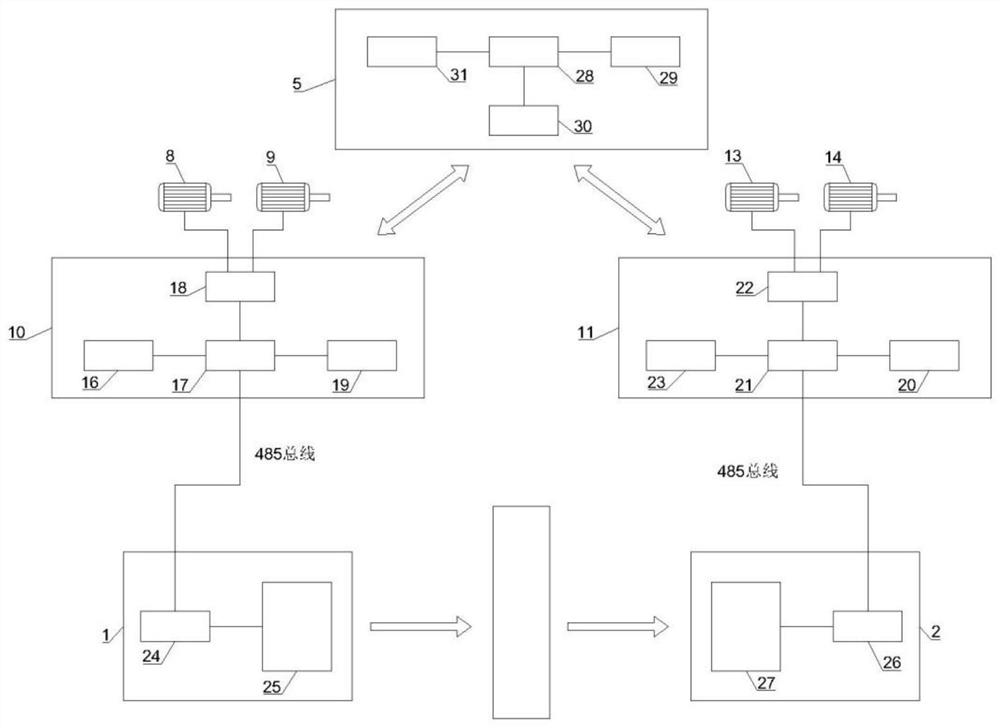

[0044] combine figure 1 , this embodiment provides a neutron transmission imaging system for prefabricated wall detection, including a neutron transmitter assembly 1 for emitting fast neutrons arranged on both sides of the prefabricated wall to be detected and a neutron transmitter assembly for The neutron receiver assembly 2 for receiving thermal neutrons, the neutron transmitter assembly 1 and the neutron receiver assembly 2 are respectively fixedly installed on a vertical wall parallel to the vertical surface where the assembled wall to be detected is located. On the first driving device 3 and the second driving device 4 moving in a two-dimensional plane, the neutron transmitter assembly 1 is connected to the first driving device 3, and the neutron receiver assembly 2 is connected to the second driving device 4 connected, and the first driving device 3 and the second driving device 4 are connected to the main control device 5 respectively.

[0045] working principle:

[0...

Embodiment 2

[0057] This embodiment provides a method for detecting the saturation of sleeve grouting in the wall of a prefabricated building by using the above-mentioned equipment, specifically:

[0058]First, the first driving device 3 and the second driving device 4 are respectively installed on both sides of the wall of the prefabricated building to be detected, and the neutron transmitter assembly 1 and the neutron receiver assembly 2 are relative to the wall of the prefabricated building to be detected The center is symmetrically arranged, and the two are synchronously moved under the respective control of the main control device 5 via the first drive device 3 and the second drive device 4, and then the following steps are performed:

[0059] S1. Determine the following parameters and input them into the main control device 5: Delineate the detection area S, the wall thickness d of the prefabricated building to be detected, the depth h of the sleeve in the detection area, the outer di...

Embodiment 3

[0071] Adopt above-mentioned apparatus and method to carry out following experiment:

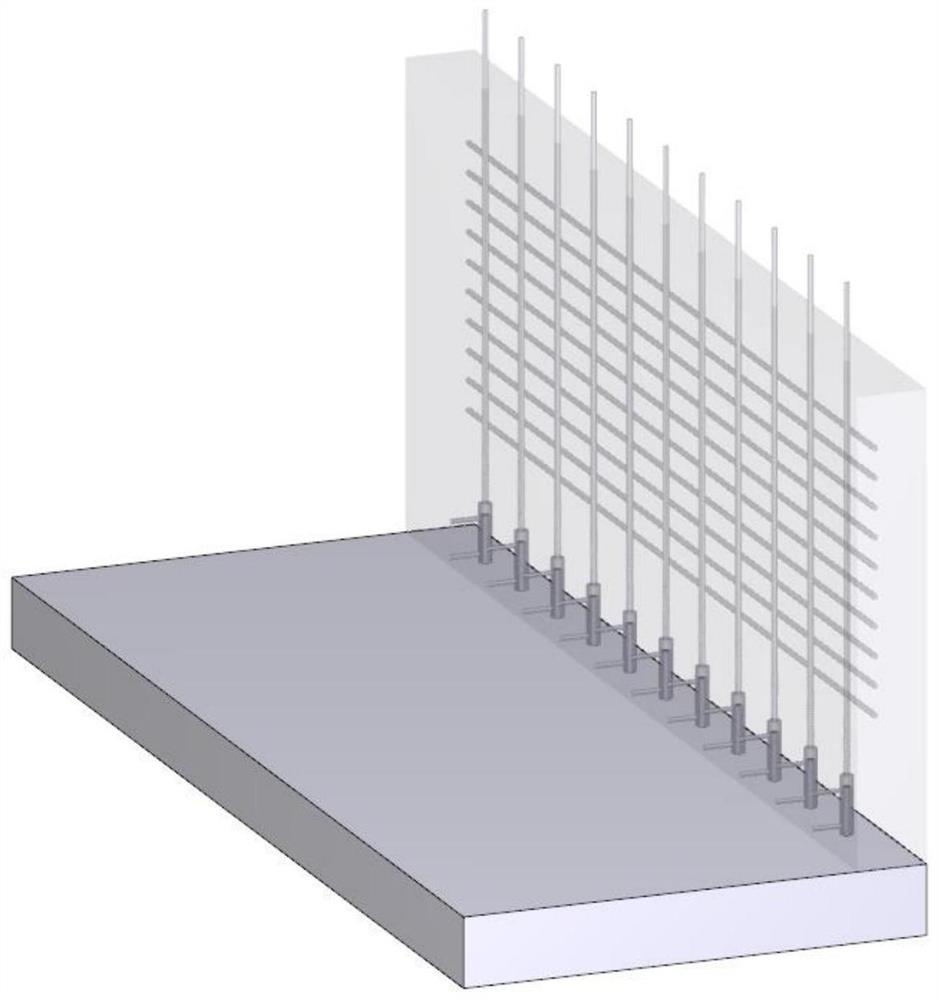

[0072] 1) use the equipment shown in embodiment 1 to such as image 3 The shown base plate and body of wall adopt the method shown in embodiment 2 to detect its connection quality, specifically:

[0073] 2) The wall thickness d is 200mm. Use equipment to calibrate and sample various parts of the wall sample plate with a thickness of 200mm, including the area A1 without any internal structure, and the area A2 containing standard sleeves, steel bars but no slurry, including standard sleeves, steel bars and slurry. area A3 of the body. Form a calibration image P A1 ( Figure 4 ), P A2 ( Figure 5 ), P A3 ( Figure 6 ).

[0074] 3) As an implementation case, select image 3 One of the connecting sleeves defines the detection area and divides the area 1 into an equally divided grid of N columns and M rows. Using a dedicated automated neutron scattering scanning imaging equipment, accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com