A kind of hollow TBM cutterhead, TBM and construction method for pilot hole expansion and excavation for inclined shafts

A hollow and cutter head technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of low construction efficiency of pilot tunnel expansion and excavation, and achieve the effects of reducing safety hazards, reducing disturbances, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

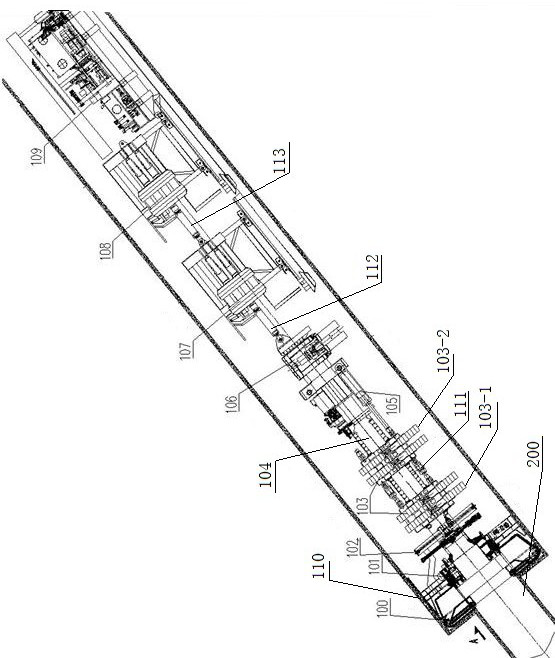

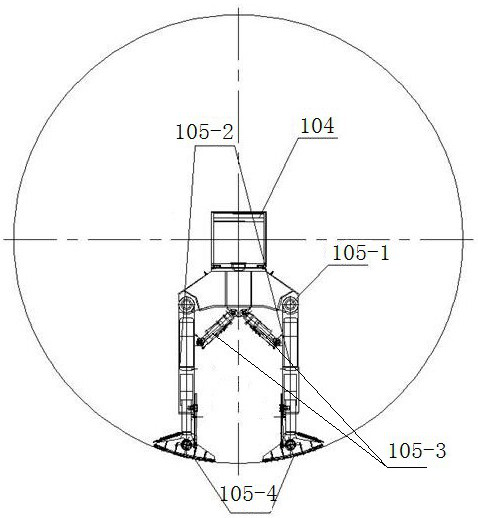

[0028] Embodiment 3, a kind of construction method of expanding the TBM with the pilot tunnel of inclined shaft as described in Embodiment 2: the steps are as follows: S1, when the TBM breaks the rock and digs, the double support shoe mechanism 103 and the bottom support 105 are supported on the cave wall , the hollow channel 2 of the hollow TBM cutter head 100 is aligned with the guide hole, the hollow TBM cutter head 100 rotates, and under the action of the propulsion force of the propulsion system (propelling oil cylinder), the hob on the hollow TBM cutter head 100 penetrates into the rock for crushing rock; the slag produced in the excavation process enters the guide hole under the action of the inner slag scraper 205 on the inner wall of the hollow passage 2 and the outer slag scraper 201 on the outer edge of the cutter head body 1, and realizes slag removal from the guide hole, and the cutter head A central slag scraper is set at the center, and the TBM discharges slag fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com