A method of 3D printing concrete special-shaped non-web reinforcement beam

A 3D printing and concrete technology, applied in the field of making concrete beams, can solve problems such as difficulties in making special-shaped beams, achieve the effects of reducing the use of redundant materials, avoiding shear damage, and simplifying construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

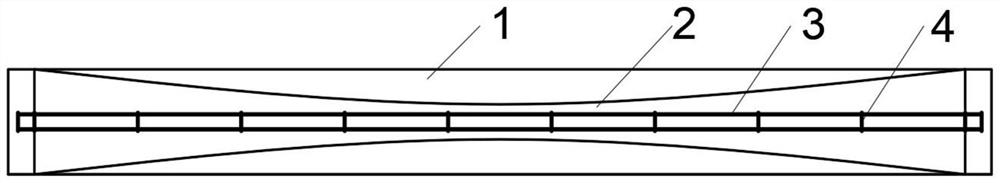

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The method of the present invention adopts the 3D concrete direct printing technology, and prints the beam member upside down.

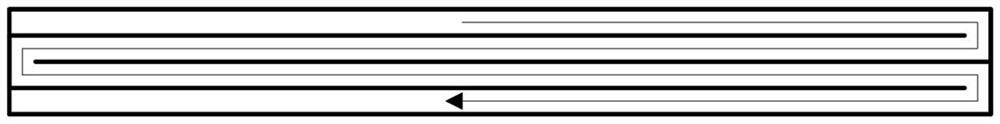

[0031] The first step is to print the rectangular flange layer 1. For the printing path, see figure 1 , because the beam flange is mainly under compression, the rectangular flange layer adopts a printing path from the edge to the center, and prints layer by layer until the design thickness of the rectangular flange layer is met.

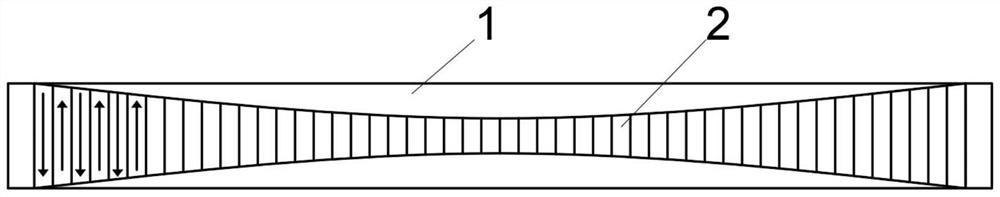

[0032] The second step is to print the curved web layer 2 on the basis of the printed rectangular flange layer. For the printing path, see figure 2 , in order to facilitate printing, print back and forth along the width of the beam in a straight Z-shaped path, and accumulate layer by layer; the outer contour of each layer of printed concrete is hyperbolic, and the length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com