Composting method for promoting humus formation

A composting method and humus technology, applied to fertilizers made from biological waste, organic fertilizers, fertilization devices, etc., can solve the problems that humus cannot provide enough precursor substances, lignocellulose has limited efficiency, and biological preparations are troublesome. Achieve the effects of increasing community diversity, facilitating compost fermentation, and improving compost efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A composting method for promoting the formation of humus, the specific steps are as follows:

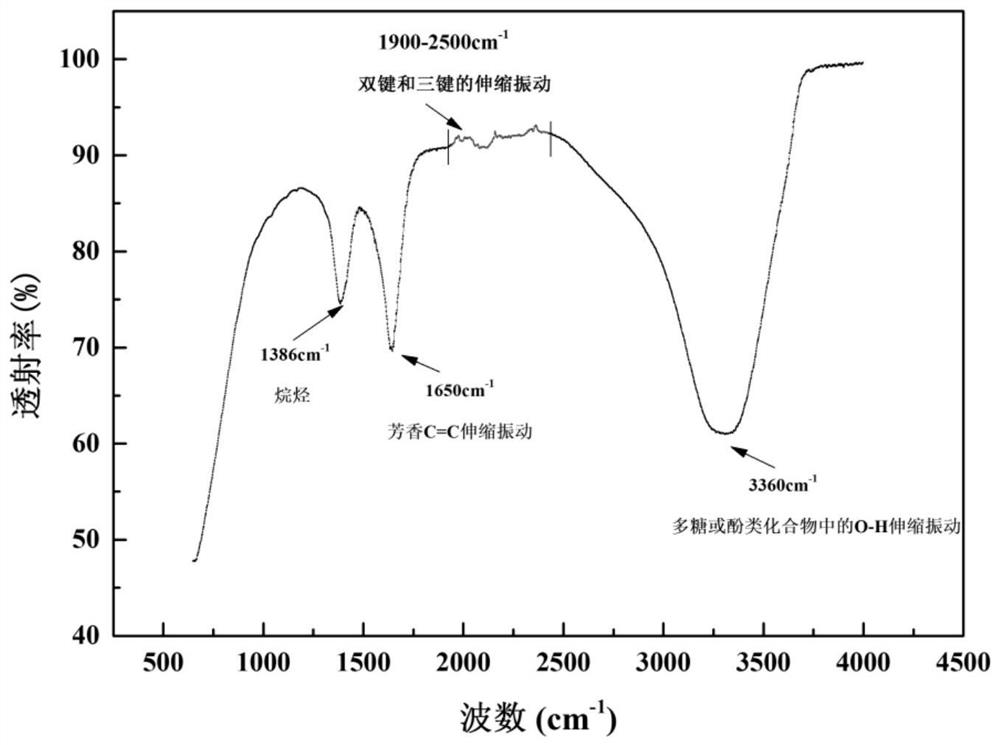

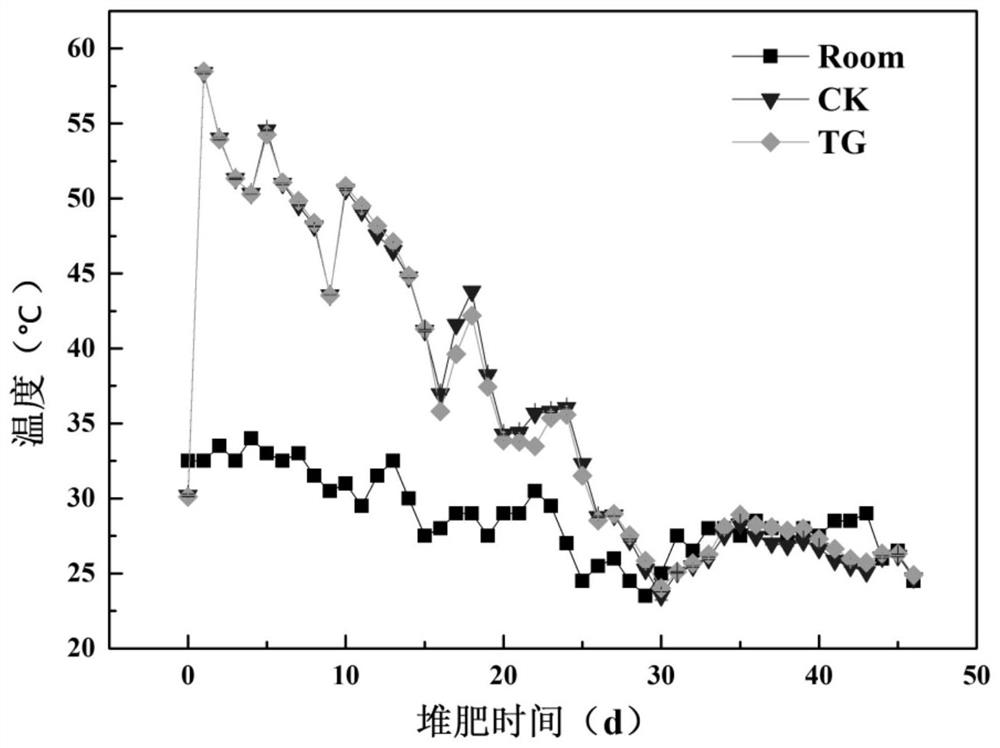

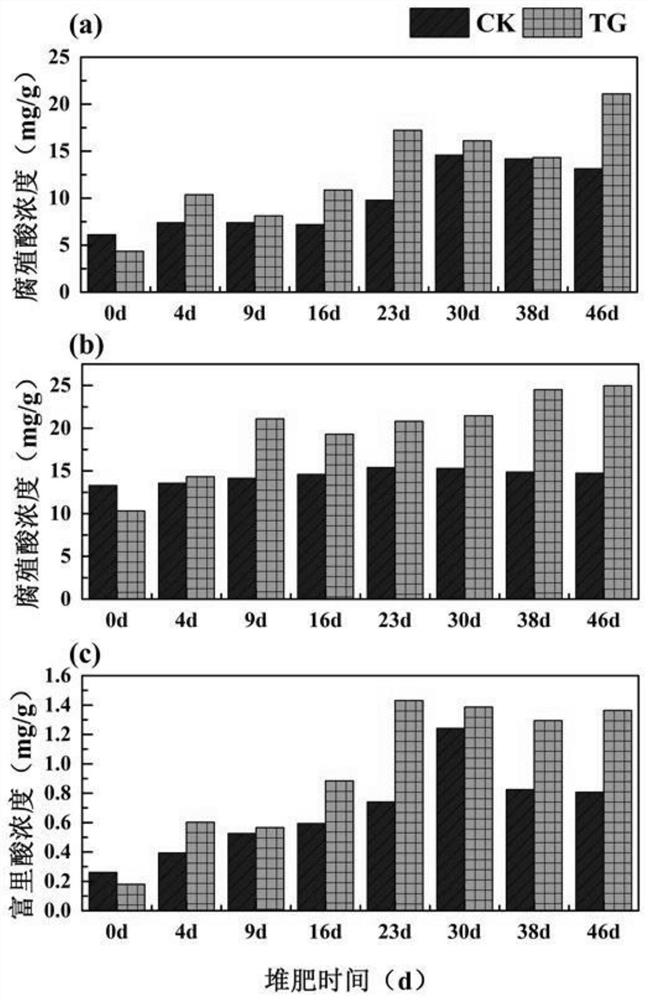

[0028] (1) Preparation of bagasse degraded derivatives (BDD): pulverize the bagasse dried to constant weight to 2-3mm, pretreat with 1.5% NaOH solution for 30min to remove most of the plant cell contents (including soluble carbohydrates, starch, organic acids, proteins, etc.), pour off the waste liquid, dry the bagasse to constant weight, and mix the dried bagasse with an ethanol solution with a volume concentration of 40% in a mass ratio of 1:20 Mix, place in an oven, and extract at 200°C until it is dried to constant weight to obtain the pretreated bagasse; mix the pretreated bagasse with nitrobenzene and NaOH with a concentration of 2 mol / L at a concentration of 1: Mix 0.1:50, place in an oven at 160°C to oxidize until dried to constant weight, then mix with deionized water at a ratio of 1:10, shake for 3 hours, centrifuge at 25°C and 10,000rpm for 10 minutes, and then filt...

Embodiment 2

[0031] A composting method for promoting the formation of humus, the specific steps are as follows:

[0032] (1) Preparation of bagasse degraded derivatives (BDD): pulverize the bagasse dried to constant weight to 2-3mm, pretreat with 1.5% NaOH solution for 30min to remove most of the plant cell contents (including soluble carbohydrates, starch, organic acids, proteins, etc.), pour off the waste liquid, dry the bagasse to constant weight, and mix the dried bagasse with an ethanol solution with a volume concentration of 40% in a mass ratio of 1:20 Mix, place in an oven, and extract at 200°C until it is dried to constant weight to obtain the pretreated bagasse; mix the pretreated bagasse with nitrobenzene and NaOH with a concentration of 2 mol / L at a concentration of 1: Mix 0.3:50, place in an oven at 160°C to oxidize until it is dried to constant weight, then mix with deionized water at a ratio of 1:10, shake for 3 hours, centrifuge at 25°C and 10,000rpm for 10 minutes, and the...

Embodiment 3

[0035] A composting method for promoting the formation of humus, the specific steps are as follows:

[0036] (1) Preparation of bagasse degraded derivatives (BDD): pulverize the bagasse dried to constant weight to 2-3mm, pretreat with 1.5% NaOH solution for 30min to remove most of the plant cell contents (including soluble carbohydrates, starch, organic acids, proteins, etc.), pour off the waste liquid, dry the bagasse to constant weight, and mix the dried bagasse with an ethanol solution with a volume concentration of 40% in a mass ratio of 1:20 Mix, place in an oven, and extract at 200°C until it is dried to constant weight to obtain the pretreated bagasse; mix the pretreated bagasse with nitrobenzene and NaOH with a concentration of 2 mol / L at a concentration of 1: Mix 0.2:50, place in an oven at 160°C to oxidize until it is dried to constant weight, then mix with deionized water at a ratio of 1:10, shake for 3 hours, centrifuge at 25°C and 10,000rpm for 10 minutes, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com