An ultra-light and high-performance sound-absorbing material with a laminated structure of carbon fiber and down

A carbon fiber layer and sound-absorbing material technology, applied in the field of sound-absorbing materials, can solve the problems of reducing the quality of sound-absorbing materials, troubles, difficulty in construction and decoration, etc., and achieve the effect of avoiding extrusion and flattening and satisfying the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

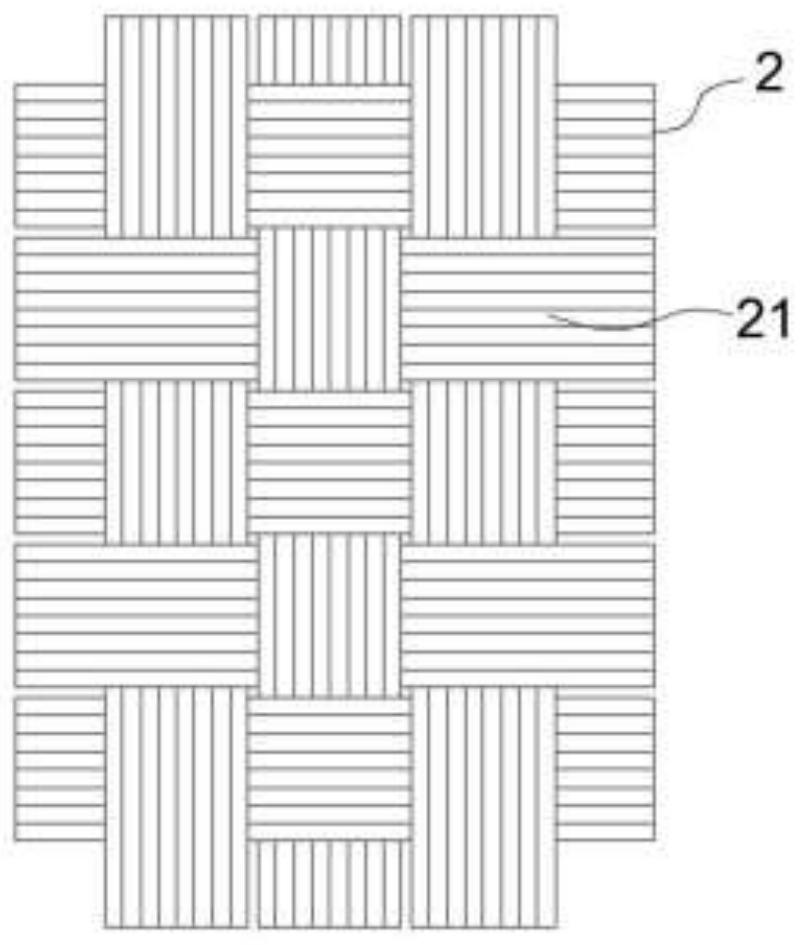

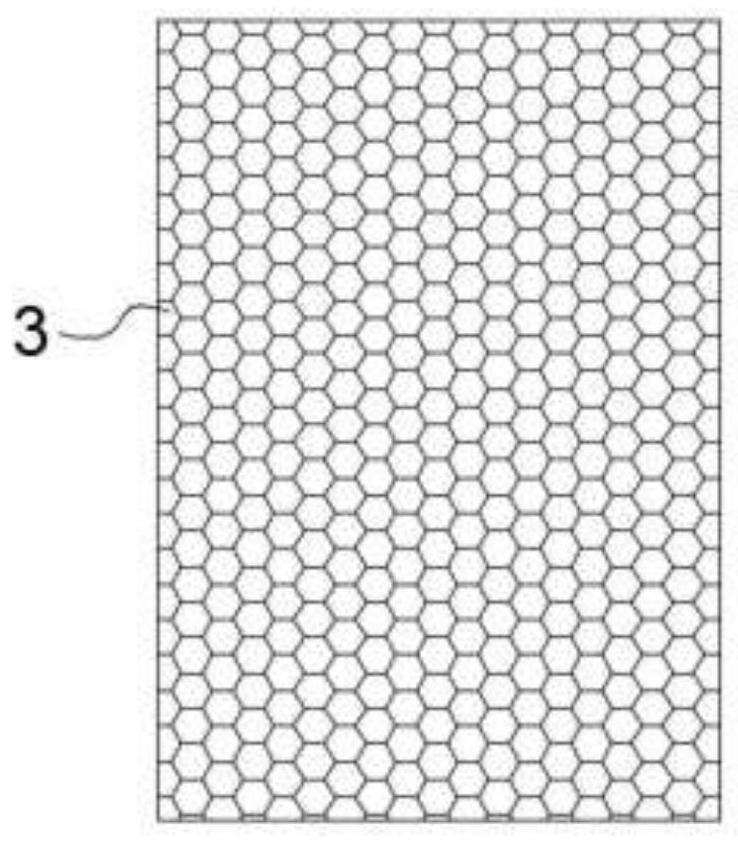

[0039] can be based on image 3 , 4 As shown, the corresponding selection is made according to the carbon fiber layer 1. Taking the preparation of a hard sound-absorbing material composed of carbon fiber boards as an example, the mesh distribution of the rubber pads 3 is adjusted according to the carbon fiber layer 1, such as image 3 As shown, when the carbon fiber layer 1 is a carbon fiber board, the honeycomb mesh setting is adopted; the diameter of the composite fiber hollow pipeline is selected as d=10mm, the wall thickness s=2mm, and the inner down filling density ρ=80%, according to the following formula:

[0040]

[0041] Among them, n-number of arrangement, d-outer diameter of composite fiber hollow pipeline, ρ-down filling density, s-wall thickness of composite fiber hollow pipeline;

[0042] It is calculated that n=8.

[0043] like figure 1 As shown in the figure, an ultra-light and high-performance sound-absorbing material with a carbon fiber and down layered s...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, except that the gaps of the rubber pads are filled with down with a filling density of 30%.

Embodiment 3

[0059] This embodiment is basically the same as Embodiment 1, except that the gaps of the rubber pads are filled with down with a filling density of 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com