Aluminum-graphite aluminum composite material structure capable of enhancing longitudinal heat conductivity coefficient

A technology of aluminum composite materials and thermal conductivity, which is applied in the fields of modification through conduction and heat transfer, electronic equipment, cooling/ventilation/heating transformation, etc., can solve problems such as graphite aluminum application constraints, and achieve improved application boundaries and longitudinal thermal conductivity. , Improve the effect of longitudinal thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

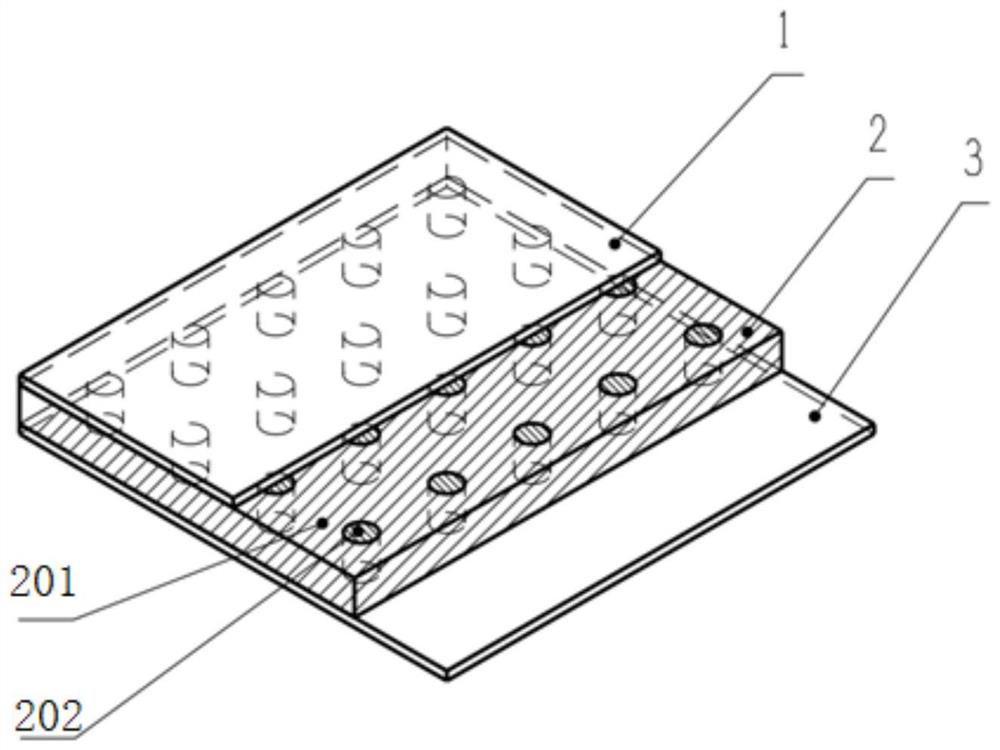

[0027] The specific structure of the aluminum-graphite-aluminum composite material configuration with enhanced longitudinal thermal conductivity in this embodiment is as follows figure 1 As shown, from top to bottom, it includes an upper aluminum alloy layer 1, a composite graphite aluminum functional layer 2 and a lower aluminum alloy layer 3, and the three layers are fused together by metallurgical methods; the composite graphite aluminum functional layer 2 includes a graphite aluminum layer 201 and several cylindrical aluminum alloy heat conduction pillars 202 embedded in the graphite aluminum layer.

[0028] Among them, the thickness of the upper aluminum alloy layer 1 is 0.5mm, and the thermal conductivity is 120w / m·k; the thickness of the lower aluminum alloy layer 3 is 0.5mm, and the thermal conductivity is 120w / m·k; the thickness of the graphite aluminum layer 201 is 2mm , the transverse thermal conductivity is 600w / m·k, the longitudinal thermal conductivity is 35w / m·k...

Embodiment 2

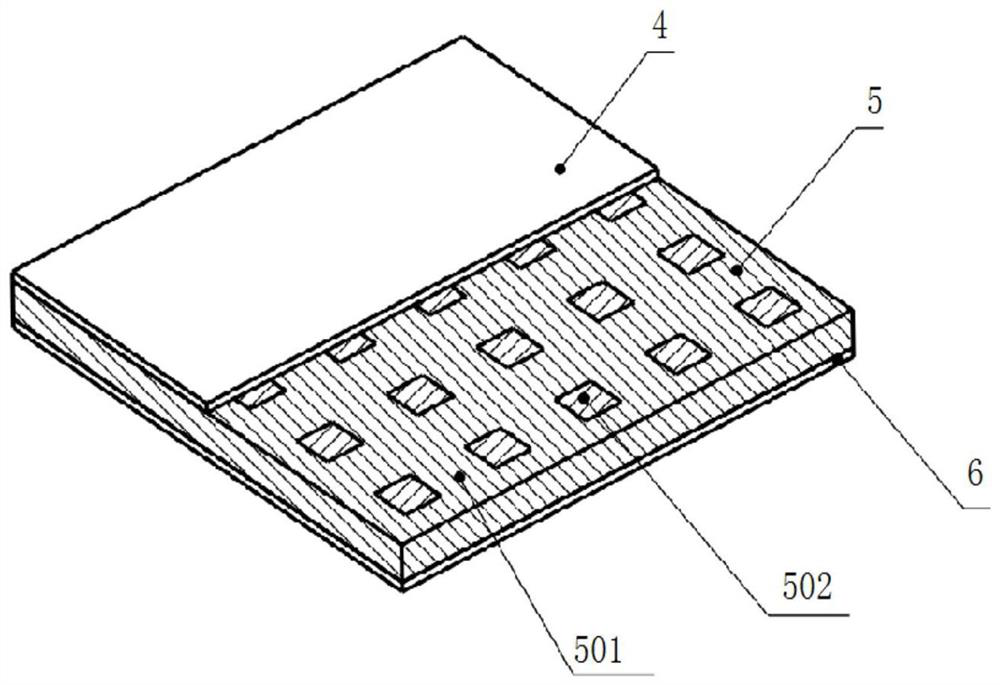

[0031] The specific structure of the aluminum-graphite-aluminum composite material configuration with enhanced longitudinal thermal conductivity in this embodiment is as follows figure 2 As shown, from top to bottom, it includes an upper aluminum alloy layer 4, a composite graphite aluminum functional layer 5 and a lower aluminum alloy layer 6, and the three layers are fused together by metallurgical methods; the composite graphite aluminum functional layer 5 includes a graphite aluminum layer 501 and several square-shaped aluminum alloy heat conduction pillars 502 embedded in the graphite aluminum layer.

[0032] Among them, the thickness of the upper aluminum alloy layer 4 is 1.1mm, and the thermal conductivity is 150w / m·k; the thickness of the lower aluminum alloy layer 6 is 0.5mm, and the thermal conductivity is 150w / m·k; the thickness of the graphite aluminum layer 501 is 3mm , the transverse thermal conductivity is 500w / m·k, the longitudinal thermal conductivity is 45w / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com