Manufacturing method of battery pack box body and battery pack box body

A manufacturing method and technology of battery packs, which are applied to battery pack parts, circuits, electrical components, etc., can solve the problems of unfavorable lightweight design, poor strength of welded parts, and low production efficiency, and achieve high die-casting efficiency and die-casting effect. The effect of high filling speed and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

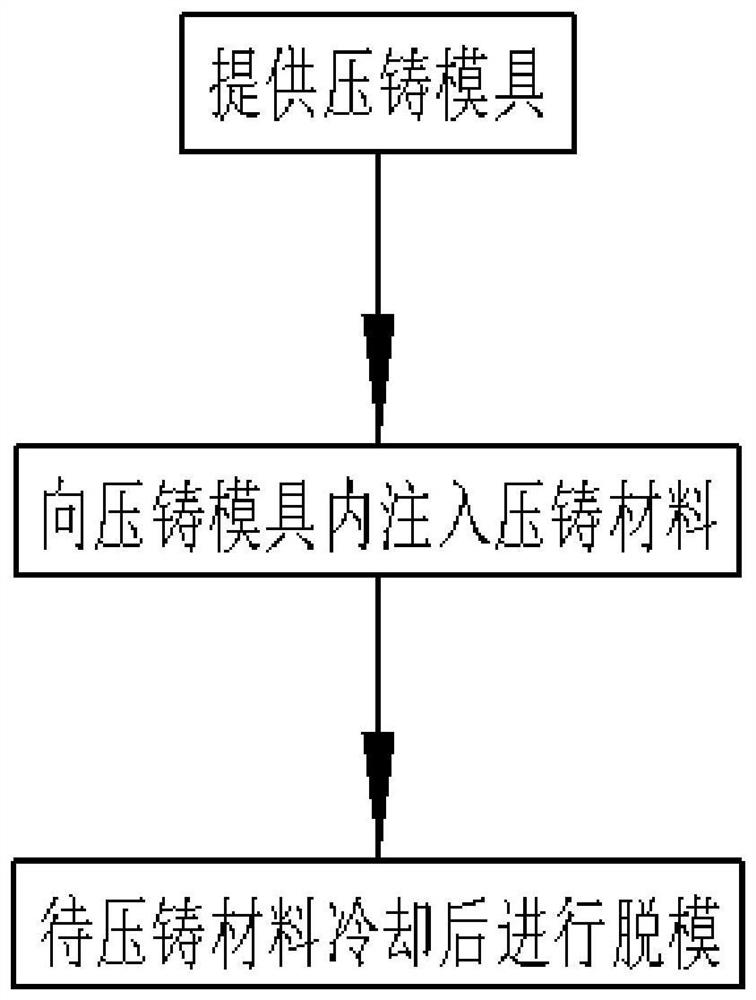

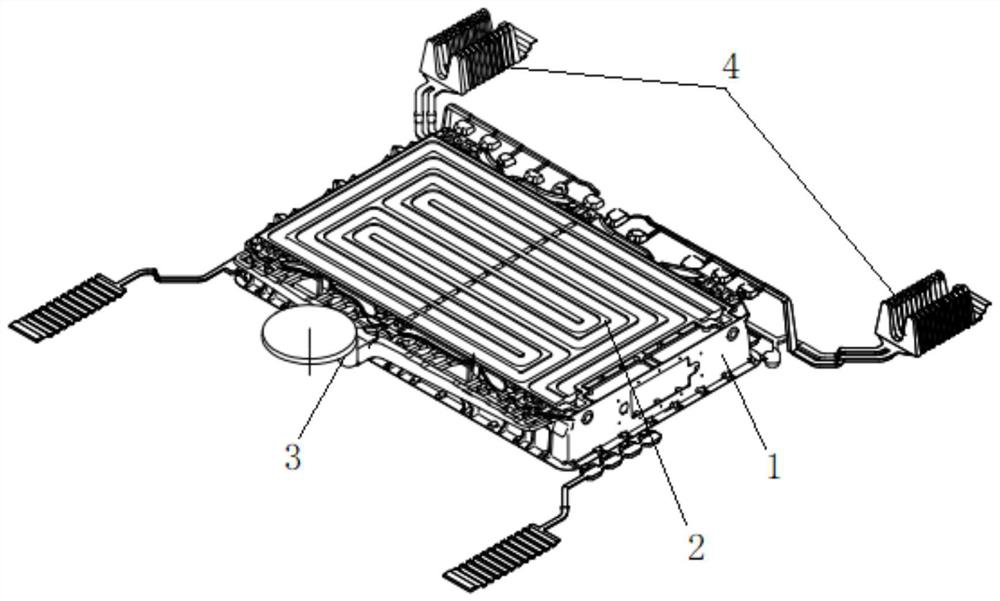

[0052] Such as figure 1 and figure 2 As shown, the present invention provides a method for manufacturing a battery pack box, including:

[0053] Provide die-casting mold 1;

[0054] Inject the die-casting material into the die-casting mold 1;

[0055] After the die-casting material is cooled, demoulding is carried out.

[0056] In this embodiment, the die casting material is AlSi10MnMg.

[0057] In this embodiment, before injecting the die-casting material into the die-casting mold 1, the die-casting mold 1 is vacuumed to ensure that the vacuum degree in the die-casting mold 1 is less than 100 mbar.

[0058] In this embodiment, a vacuum pump is used to evacuate the die-casting mold 1 .

[0059] In this embodiment, when the die-casting material is injected into the die-casting die 1, the die-casting die 1 is heated to ensure that the temperature of the die-casting die 1 is 220°C-230°C.

[0060] In this embodiment, a mold temperature machine is used to heat the die-castin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com