Online cleaning method for reverse osmosis membrane element based on combined pollution

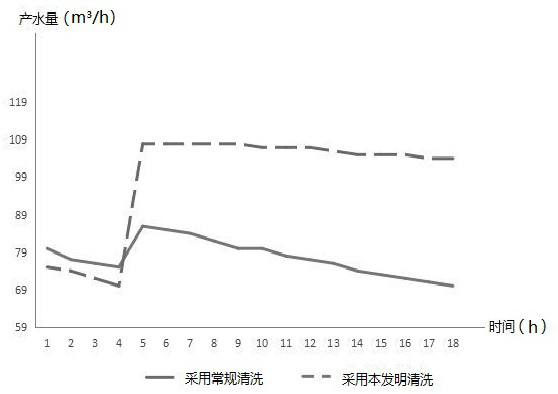

A reverse osmosis membrane and complex pollution technology, which is applied in the direction of reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc., can solve the problems of poor effect, extend the cleaning cycle, improve the cleaning recovery effect, and reduce the system performance attenuation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

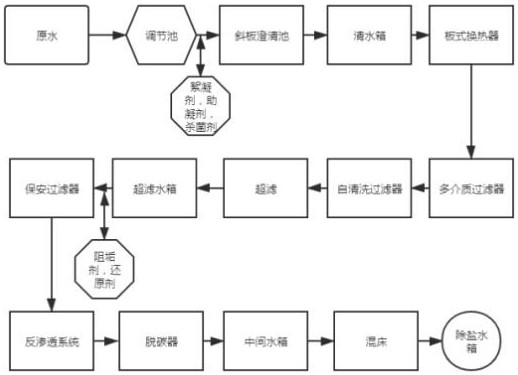

Method used

Image

Examples

Embodiment 1

[0028]An online cleaning method for reverse osmosis membrane elements based on compound pollution.

[0029]The technical solution is: including the following steps:

[0030](1) Perform the first sterilization and cleaning of the first and second-stage reverse osmosis membrane elements: the first and second-stage reverse osmosis membrane elements are all cleaned with sterilizing cleaning fluid, and each stage is cycled for 0.1h, then soaked for 0.1h, and then used for reverse osmosis. The permeating product water is flushed to neutrality, the cleaning flow is controlled at 4m³ / h / pressure vessel, and the cleaning pressure is controlled at 0.1Mpa; the sterilization cleaning liquid uses 2,2-bisbromo-3-nitrilopropionamide 500ppm aqueous solution.

[0031](2) Intensified alkaline cleaning of a section of reverse osmosis membrane element: using an intensified alkaline cleaning solution, first cycle for 1h, first soak for 1h, and then perform second cycle for 1h and second soak in sequence After 1h,...

Embodiment 2

[0038]An online cleaning method for reverse osmosis membrane elements based on compound pollution.

[0039]The technical solution is: including the following steps:

[0040](1) Carry out the first sterilization and cleaning of the first and second-stage reverse osmosis membrane elements: the first and second-stage reverse osmosis membrane elements are both cleaned with sterilizing cleaning fluid, and each stage is cycled for 0.2h, then soaked for 0.2h, and then used for reverse osmosis. The permeate product water is flushed to neutrality, the cleaning flow is controlled at 6m³ / h / pressure vessel, and the cleaning pressure is controlled at 0.2Mpa; the sterilization cleaning liquid uses 800ppm aqueous solution of 2,2-bisbromo-3-nitrilopropionamide.

[0041](2) Intensified alkaline cleaning of a section of reverse osmosis membrane elements: using an intensified alkaline cleaning solution, the first cycle of 1.5h, the first immersion for 1.5h, and the second cycle of 1.5h, the first Secondly soak...

Embodiment 3

[0048]An online cleaning method for reverse osmosis membrane elements based on compound pollution.

[0049]The technical solution is: including the following steps:

[0050](1) Carry out the first sterilization and cleaning of the first and second-stage reverse osmosis membrane elements: the first and second-stage reverse osmosis membrane elements are both cleaned with sterilizing cleaning fluid, and each stage is cycled for 0.6h, then soaked for 0.6h, and then used for reverse osmosis. The permeate product water is flushed to neutral, the cleaning flow is controlled at 9m³ / h / pressure vessel, and the cleaning pressure is controlled at 0.3Mpa; the sterilization cleaning liquid uses 2,2-bisbromo-3-nitrilopropionamide 1500ppm aqueous solution.

[0051](2) Intensified alkaline cleaning of a section of reverse osmosis membrane elements: using an enhanced alkaline cleaning solution, the first cycle of 2.5h, the first immersion for 2.5h, and then the second cycle of 2.5h, the first Secondly soak fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com